Super-hydrophobic demulsifying oil-water separation membrane material, preparation method and application thereof

A super-hydrophobic, emulsifiable oil technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve problems such as harsh conditions, complex processes, and high energy consumption, and achieve good separation ability and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

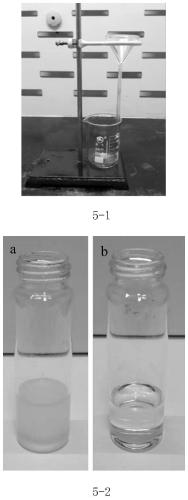

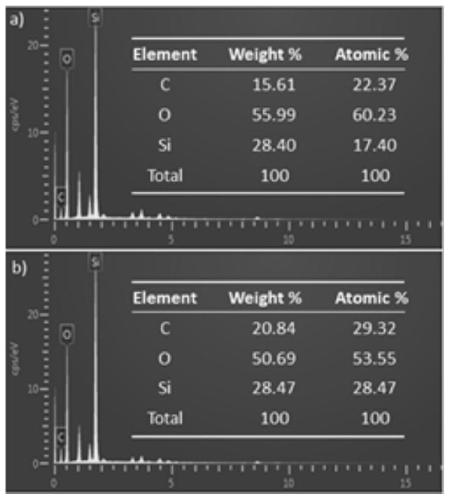

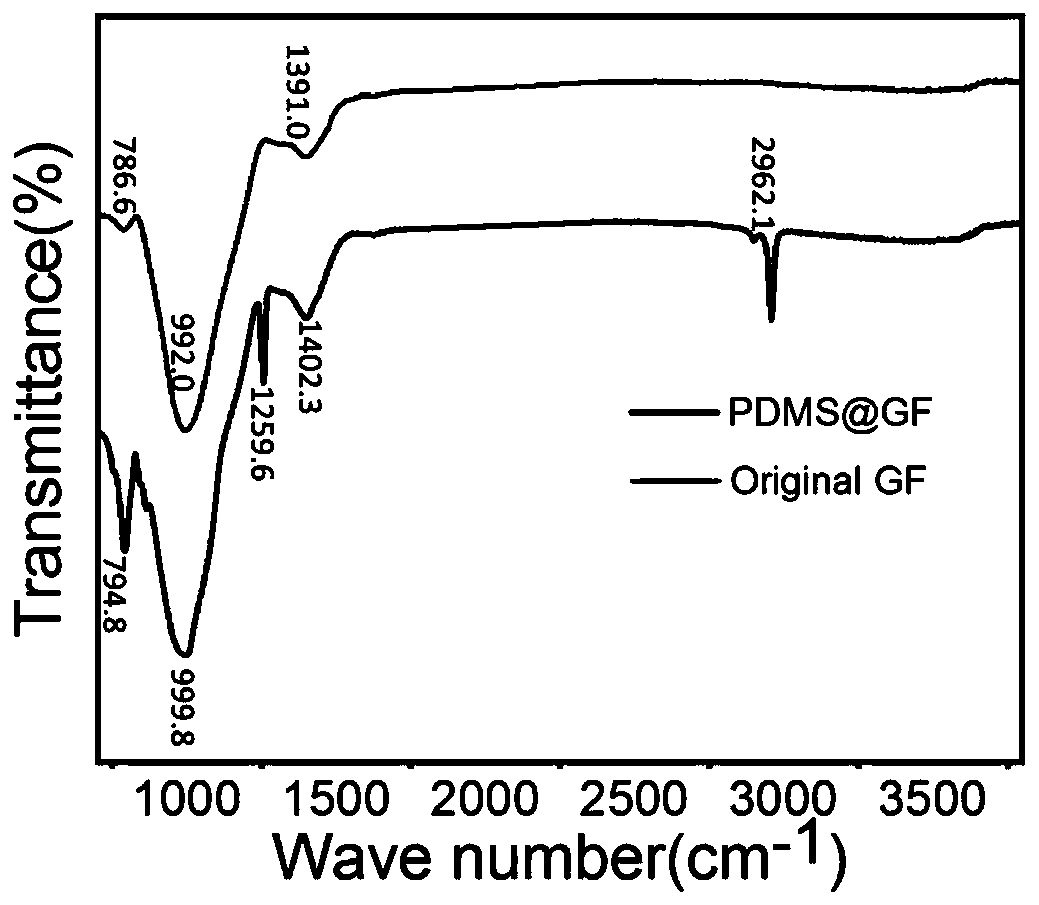

[0043]A kind of preparation method of superhydrophobic demulsification oil-water separation membrane material (PDMS glass fiber filter membrane), concrete steps are as follows:

[0044] (1) Add 1 g of polydimethylsiloxane (PDMS) solution into 100 g of organic solvent n-hexane solution, and stir magnetically for 30 minutes to mix PDMS and organic solvent evenly to obtain polydimethylsiloxane with a mass concentration of 1%. PDMS-n-hexane mixed solution;

[0045] (2) Take out the glass fiber filter membrane, first use ethanol and deionized water to carry out ultrasonic cleaning to the glass fiber filter membrane, and then after washing with distilled water, dry in an oven until completely dry;

[0046] (3) Soak the dried glass fiber filter membrane in the PDMS-n-hexane mixed solution, soak the glass fiber filter membrane 5 times repeatedly to ensure that the glass fiber filter membrane is completely soaked by the PDMS-n-hexane mixed solution;

[0047] (4) Take out the glass fib...

Embodiment 2

[0079] A kind of preparation method of superhydrophobic demulsification oil-water separation membrane material (PDMS glass fiber filter membrane), concrete steps are as follows:

[0080] (1) Add 5 g of polydimethylsiloxane (PDMS) solution into 100 g of organic solvent n-hexane solution, and stir magnetically for 30 minutes to mix PDMS and organic solvent evenly to obtain polydimethylsiloxane with a mass concentration of 5%. PDMS-n-hexane mixed solution;

[0081] (2) Take out the glass fiber filter membrane, first use ethanol and deionized water to carry out ultrasonic cleaning to the glass fiber filter membrane, and then after washing with distilled water, dry in an oven until completely dry;

[0082] (3) Soak the dried glass fiber filter membrane in the PDMS-n-hexane mixed solution, soak the glass fiber filter membrane 5 times repeatedly to ensure that the glass fiber filter membrane is completely soaked by the PDMS-n-hexane mixed solution;

[0083] (4) Take out the glass fi...

Embodiment 3

[0086] A kind of preparation method of superhydrophobic demulsification oil-water separation membrane material (PDMS glass fiber filter membrane), concrete steps are as follows:

[0087] (1) Add 10 g of polydimethylsiloxane (PDMS) solution into 100 g of organic solvent n-hexane solution, and stir magnetically for 30 minutes to mix PDMS and organic solvent evenly to obtain polydimethylsiloxane with a mass concentration of 10%. PDMS-n-hexane mixed solution;

[0088] (2) Take out the glass fiber filter membrane, first use ethanol and deionized water to carry out ultrasonic cleaning to the glass fiber filter membrane, and then after washing with distilled water, dry in an oven until completely dry;

[0089] (3) Soak the dried glass fiber filter membrane in the PDMS-n-hexane mixed solution, soak the glass fiber filter membrane 5 times repeatedly to ensure that the glass fiber filter membrane is completely soaked by the PDMS-n-hexane mixed solution;

[0090] (4) Take out the glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com