A kind of preparation method of superhydrophilic polymer film with demulsification function

A polymer membrane and super-hydrophilic technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as complicated process and difficult emulsion separation of emulsion, and achieve excellent separation performance and good reusability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) After the solid polyvinylidene fluoride powder and styrene maleic anhydride powder are vacuum-dried at 40°C to remove moisture, they are dissolved in DMAc, and lithium chloride is added as a porogen to prepare a casting solution with a concentration of 20 wt%. Heat and stir at 70°C for 8 hours, dissolve into a transparent homogeneous solution, and then stand at constant temperature at 70°C for defoaming. Using the immersion precipitation phase inversion method, scrape the casting solution evenly on the glass plate at room temperature (20°C) to form a liquid film with a thickness of 300 μm, and quickly immerse it in the coagulation bath to form a film, and then the formed polysegregation The vinyl fluoride / styrene maleic anhydride blend film was taken out from the coagulation bath and soaked in deionized water (room temperature 20°C).

[0031] (2) Prepare a hyperbranched polyoxypropylene polyoxyethylene polyether aqueous solution, add a catalyst, ultrasonically vibra...

Embodiment 2

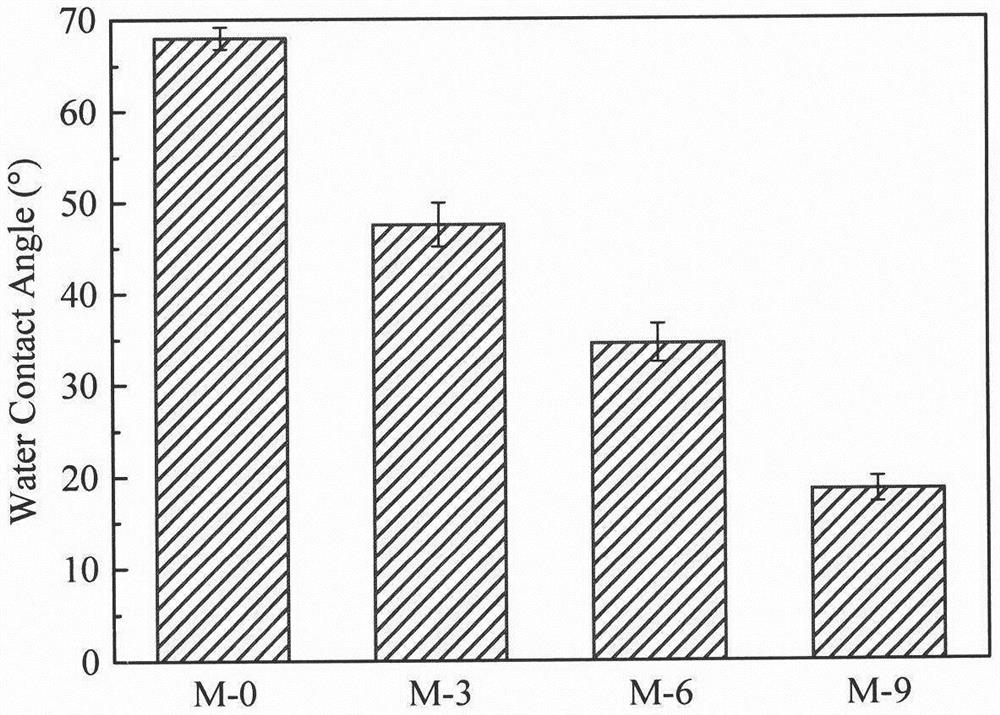

[0033] Prepare superhydrophilic polyvinylidene fluoride oil-water separation membrane with the method described in Example 1, wherein the grafting reaction time is respectively 0h, 3h, 6h, 9h, and is respectively denoted as M-0, M-3, M-6 and M-9. The surface contact angle of the superhydrophilic polyvinylidene fluoride oil-water separation membrane made by optical contact angle measuring instrument is measured, and the results are shown in image 3 . From image 3 It can be clearly seen that the pure water contact angle of the ungrafted polyvinylidene fluoride / styrene maleic anhydride blend film surface is only 67.5°, which does not reach the superhydrophilic state. With the increase of grafting time, the more hyperbranched polyether grafted on the membrane surface, the contact angle decreased gradually. The angle decreased to 18.5° at 9 hours of grafting, realizing the superhydrophilic property.

Embodiment 3

[0035] Taking the super-hydrophilic polyvinylidene fluoride oil-water separation membrane M-9 prepared in Example 2 as the experimental object, the separation performance of different oil-water emulsions was measured using a filter device at room temperature. The dichloromethane system was obtained by stirring 0.5g sodium lauryl sulfate, 114mL dichloromethane and 1mL water at room temperature for 3h; the kerosene system was obtained by stirring 0.5g sodium lauryl sulfate, 10mL kerosene and 1L water at room temperature for 3h. The separation results are shown in Table 1.

[0036] The oil-water separation performance of the superhydrophilic polyvinylidene fluoride oil-water separation membrane M-9 prepared in the embodiment 2 of table 1

[0037]

[0038] *Separation efficiency = (TOC of raw solution before membrane separation-TOC in permeate of membrane separation) / TOC of raw solution before membrane separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com