A kind of silicon-containing cationic polyacrylamide and its application

A polyacrylamide, cationic technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of oil droplet adsorption and insignificant coalescence effect, achieve high COD removal rate and solid sedimentation rate, promote oil The effect of drip coalescence and high removal rate of oily substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

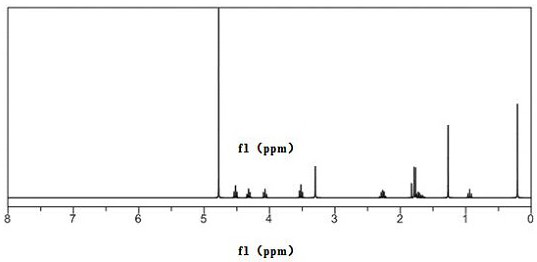

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of modified cationic polyacrylamide

[0032] In parts by weight, the following raw material components are used:

[0033] (1) 35 parts of acrylamide;

[0034] (2) 25 parts of acryloyloxyethyltrimethylammonium chloride;

[0035] (3) 0.0025 parts of pentasodium diethylenetriaminepentaacetate;

[0036] (4) 0.001 part of adipic acid;

[0037] (5) 60 parts deionized water;

[0038] (6) 2 parts Tween 20.

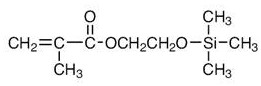

[0039] After distributing the above raw material components into a uniform solution, add 2 parts of 2-(trimethylsilyloxy)ethyl methacrylate, and stir for 10 minutes under high-speed stirring at 10,000 rpm to obtain a polymerization solution and add it to the reaction In the kettle, pass nitrogen to remove oxygen until the oxygen content is lower than 0.2%. Adjust the temperature of the system in the reaction kettle at 2-3°C with a water bath, dissolve 0.0005 parts of ammonium persulfate and 0.0005 parts of sodium thiosulfate in 1 part of deionize...

Embodiment 2

[0040] Example 2 Preparation of modified cationic polyacrylamide

[0041] In parts by weight, the following raw material components are used:

[0042] (1) 45 parts of acrylamide;

[0043] (2) 35 parts of methacryloyloxyethyltrimethylammonium chloride;

[0044] (3) 0.005 parts of pentasodium diethylenetriaminepentaacetate;

[0045] (4) 0.002 parts of glutaric acid;

[0046] (5) 75 parts deionized water;

[0047] (6) 3 servings Tween 60.

[0048]After distributing the above-mentioned raw material components into a uniform solution, add 3 parts of 2-(trimethylsiloxy)ethyl methacrylate, and stir for 10 minutes under high-speed stirring at 10,000 rpm to obtain a polymerization solution and add it to the reaction In the kettle, pass nitrogen to remove oxygen until the oxygen content is lower than 0.2%. Adjust the temperature of the system in the reactor by a water bath at 2-3°C, dissolve 0.00065 parts of ammonium persulfate and 0.00065 parts of sodium thiosulfate in 1 part of ...

Embodiment 3

[0050] Example 3 Preparation of modified cationic polyacrylamide

[0051] In parts by weight, the following raw material components are used:

[0052] (1) 55 parts of acrylamide;

[0053] (2) 55 parts of acryloyloxyethyltrimethylammonium chloride;

[0054] (3) 0.01 part of pentasodium diethylenetriaminepentaacetate;

[0055] (4) 0.003 parts of succinic acid;

[0056] (5) 85 parts deionized water;

[0057] (6) 5 servings Tween 80.

[0058] After distributing the above-mentioned raw material components into a uniform solution, add 5 parts of 2-(trimethylsiloxy)ethyl methacrylate, and stir for 10 minutes under high-speed stirring at 10,000 rpm to obtain a polymerization solution and add it to the reaction In the kettle, pass nitrogen to remove oxygen until the oxygen content is lower than 0.2%. Adjust the temperature of the system in the reactor to 2-3°C with a water bath, dissolve 0.00075 parts of ammonium persulfate and 0.00075 parts of sodium thiosulfate in 1 part of dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com