Production method of glass fiber mesh cover

A technology of glass fiber mesh and production method, which is applied in the field of glass fiber, can solve the problems of decreased bonding strength, ecological environment hazards, sand discs, sand disc flying pieces, etc., and achieves increased interlayer adhesion and uniform internal structure , to reduce the effect of delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

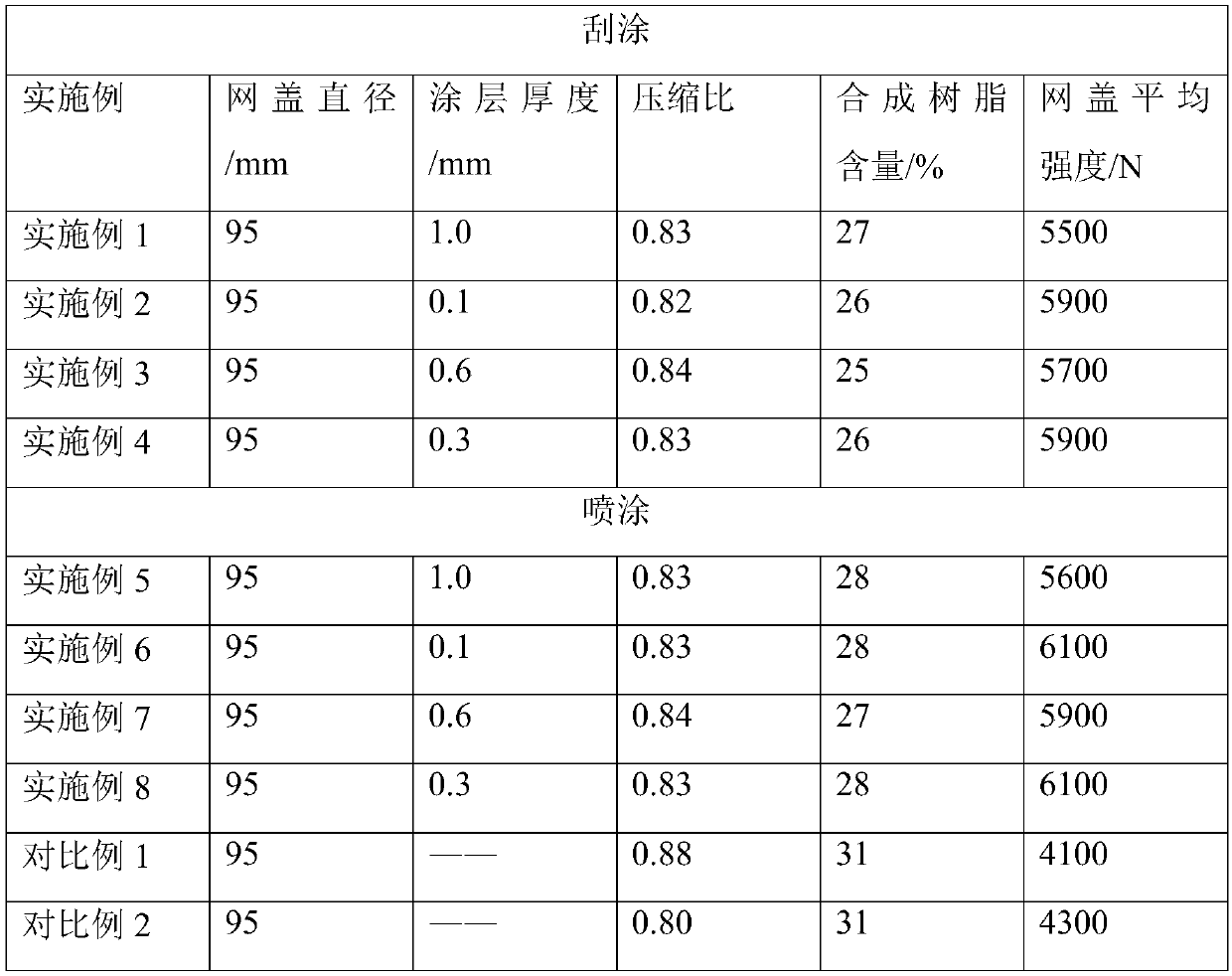

Examples

Embodiment 1

[0047] A method for producing a glass fiber mesh cover, comprising the steps of:

[0048] Step 1, impregnating the glass fiber cloth in the phenolic resin, then pre-baking, and set aside;

[0049] Step 2, using a curing device to cure the leftover material in the production process of the glass fiber mesh cover to obtain a cured material;

[0050] Step 3. For the solidified material obtained in step 2, use a cutting device to cut the leftover material into irregular small pieces of 1cm to 10cm, and then use a crushing device to crush the cut irregular small pieces to obtain Crushed leftover material, which includes resin-wrapped fiber particles of 0.15 mm to 1.5 mm, chopped fibers of 0.3 mm to 10 mm, and synthetic resin particles of ≤0.5 mm;

[0051] Step 4: Compounding the crushed leftover material obtained in step 3 with phenolic resin using compounding equipment to form a uniform mixed solution. The composition and weight ratio of the mixed solution are as follows: the cru...

Embodiment 2

[0058] A method for producing a glass fiber mesh cover, comprising the steps of:

[0059] Step 1, impregnating the glass fiber cloth in the phenolic resin, then pre-baking, and set aside;

[0060] Step 2, use the dust removal equipment to collect the leftovers produced when the glass fiber mesh cover in Example 1 is rounded, then use the compounding equipment to compound the leftovers and phenolic resin to a uniform mixed solution, the mixed solution The components and weight ratio are, the leftover material is 60%, and the phenolic resin is 40%;

[0061] Step 3, the mixed solution that step 2 is made, utilize scraping equipment to scrape and coat on the glass fiber cloth that is processed through step 1, form coating on glass fiber cloth, the last 0.1mm of described coating thickness;

[0062] Step 4. Use the baking equipment to pre-bake the glass fiber cloth treated in step 3. According to the specifications of the glass fiber mesh cover and the requirements for the strengt...

Embodiment 3

[0067] A method for producing a glass fiber mesh cover, comprising the steps of:

[0068] Step 1, impregnating the glass fiber cloth in the phenolic resin, then pre-baking, and set aside;

[0069] Step 2, collecting the leftover material produced in the step seven of the glass fiber net cover in embodiment 1 or the step five in the embodiment 2, utilizing the curing equipment to solidify the leftover material to obtain a cured material;

[0070] Step 3. For the solidified material obtained in step 2, use a cutting device to cut the leftover material into irregular small pieces of 1 cm to 7 cm, and then use a crushing device to crush the cut irregular small pieces to obtain The leftover crushed product, the leftover crushed product includes resin-wrapped fiber particles of 0.15 mm to 1.5 mm, chopped fibers of 0.3 to 10 mm, and synthetic resin particles of ≤0.5 mm;

[0071] Step 4: Compounding the crushed leftover material obtained in step 3 with phenolic resin using compoundin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com