Explosion-proof and flame-retardant device for micropowder recovering containers and transport vehicle tank bodies and special equipment of explosion-proof and flame-retardant device

A special equipment and fine powder technology, applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of small loading capacity, large specific surface area of fine powder, difficult unloading, etc., to solve the problem of explosion and spontaneous combustion, Effect of reducing air occupancy rate and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

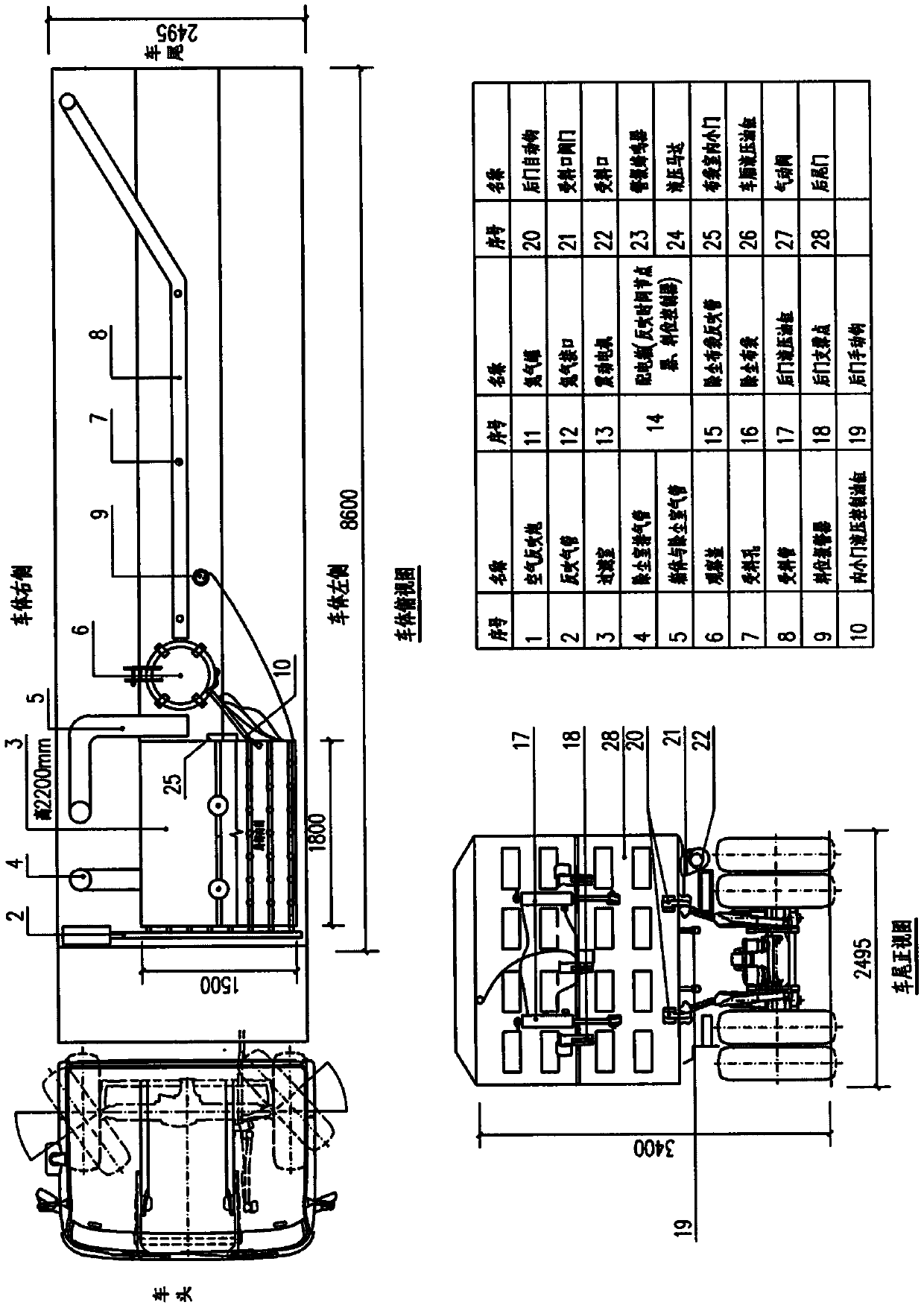

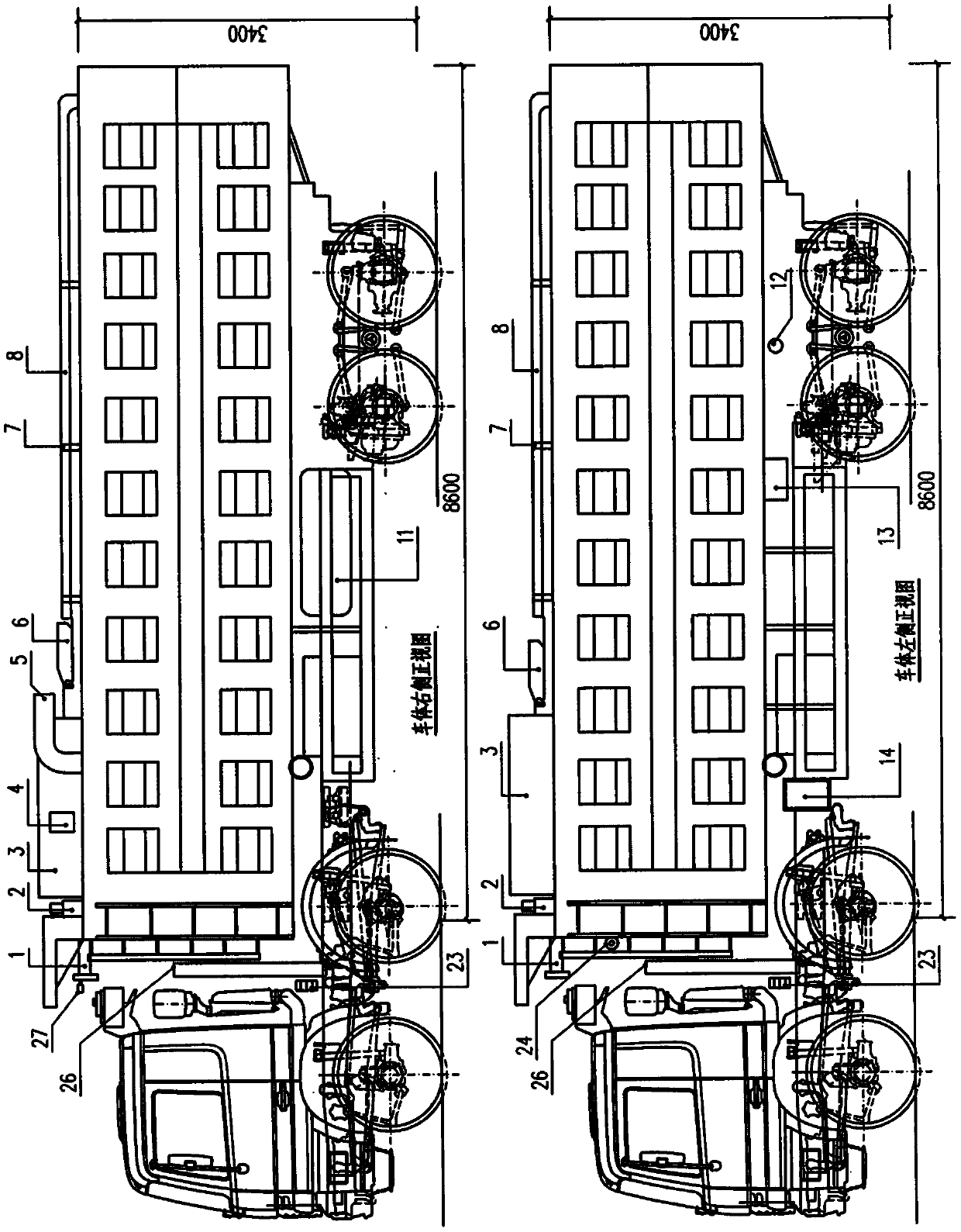

[0010] 1. Park the recycling container or the tank body of the transport vehicle at a position convenient for the ash connection port of the vehicle, connect the material nozzle with the ash connection port (22) of the recovery container or the tank body of the transport vehicle, and open the ash delivery port valve (21) .

[0011] 2. Connect the on-site nitrogen flow pipe to the nitrogen port (12) of the recovery container or the tank of the transport vehicle.

[0012] 3. Turn on the back blowing power supply and the material level alarm power supply (14), and the material level alarm and back blowing time relay (14) start to work.

[0013] 4. Start to transport materials with nitrogen, the setting time of the pneumatic valve (27) is 2 to 5 minutes, and the air pressure of the dust bag back blowing is about 0.5 to 0.8 MPa. When the material level sensor (9) senses the material, the sensed data is transmitted to the material level controller (14). When the data sensed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com