Grease waste liquid treatment device

A waste liquid treatment and grease technology, which is applied in the direction of grease/oily substance/suspton removal device, water treatment under temperature conditions, biological water/sewage treatment, etc., can solve the problem of affecting the normal metabolic process of activated sludge and biofilm, and affecting aquatic The living environment of organisms and fish, and the impact on the water passing capacity of urban drainage pipe networks, etc., to speed up the oil-water separation rate, improve the oil-water separation effect, and facilitate the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the directional terms and order terms mentioned in the following embodiments, such as "upper", "lower", "front", "back", "left", "right", etc., are only referring to the accompanying drawings. Direction, therefore, the use of directional terms is for illustration and not for limitation of the invention.

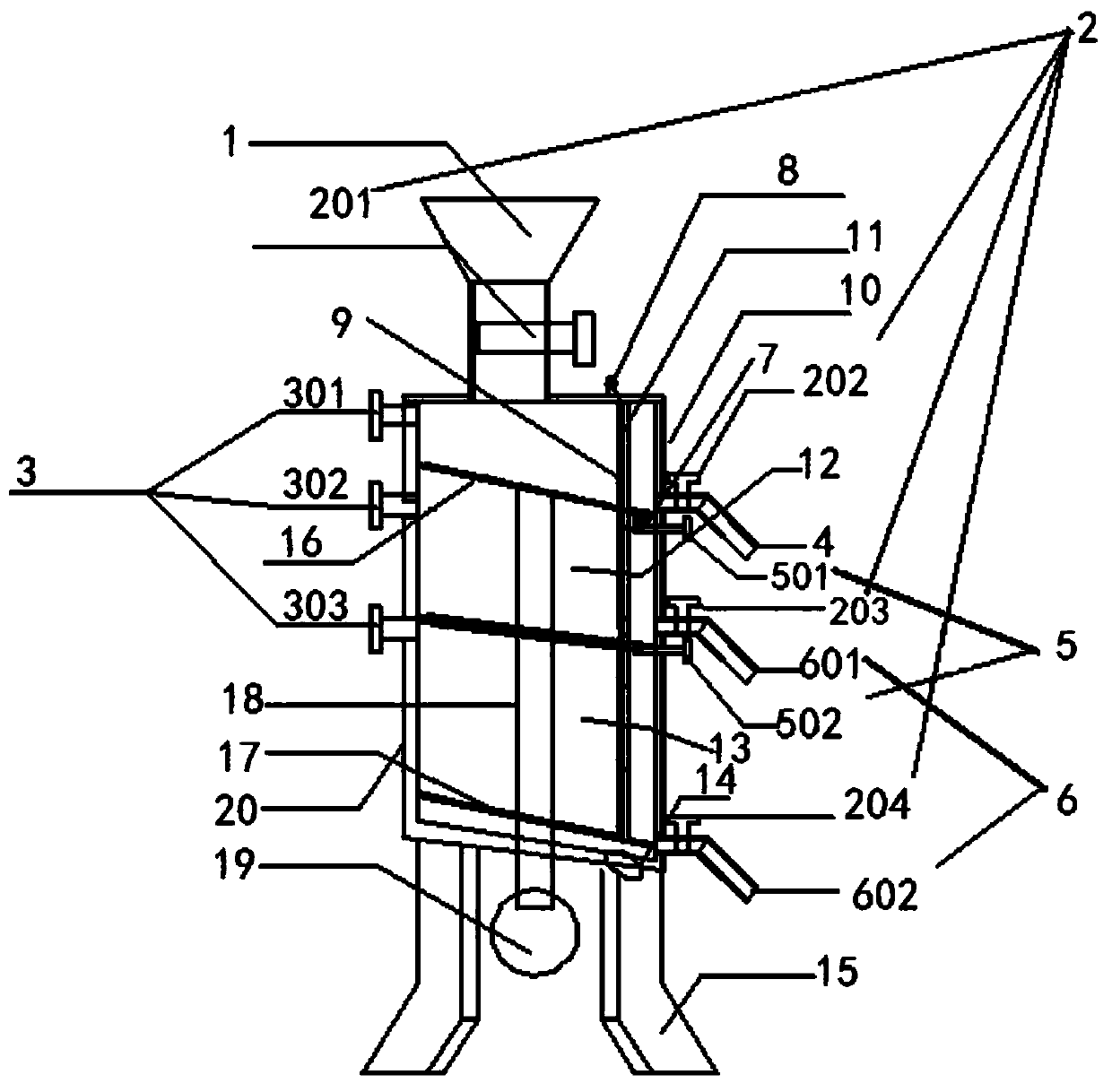

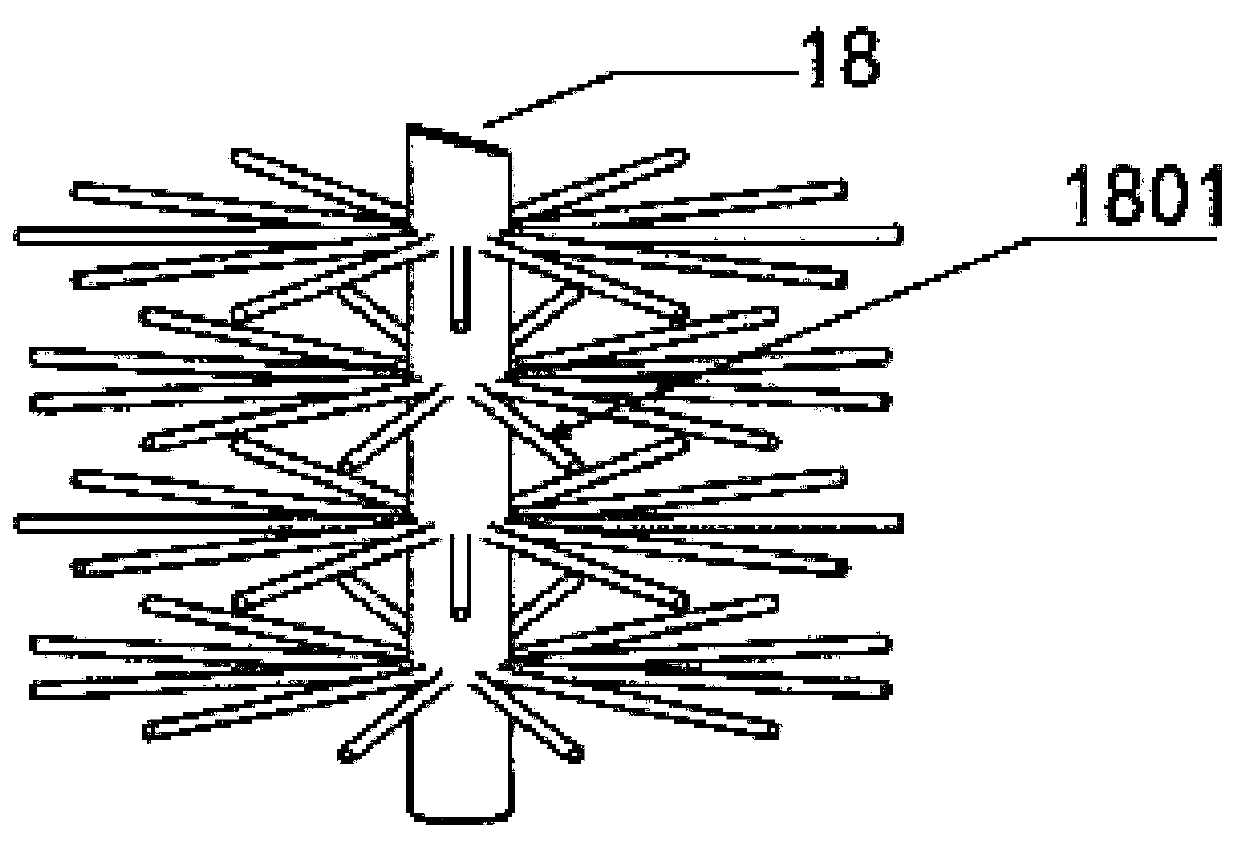

[0050] Such as figure 1 As shown, the grease waste treatment device used in the present invention includes a treatment box, an aeration system, a shaft system 18 , a central shaft drive system 19 and a temperature control system 20 , and the treatment box is installed on the bottom bracket 15 . In order to facilitate a better understanding of the present invention, the number of partitions will be described as two in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com