A kind of lipid-protein edible bilayer active film and preparation method thereof

A protein and lipid technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, flat products, etc., can solve the problems of difficult to control film thickness and uniformity, prone to cracks or holes, anaerobic respiration of fruits and vegetables, etc. Achieve the effect of saving casting process, not easy to fall off and brittle, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

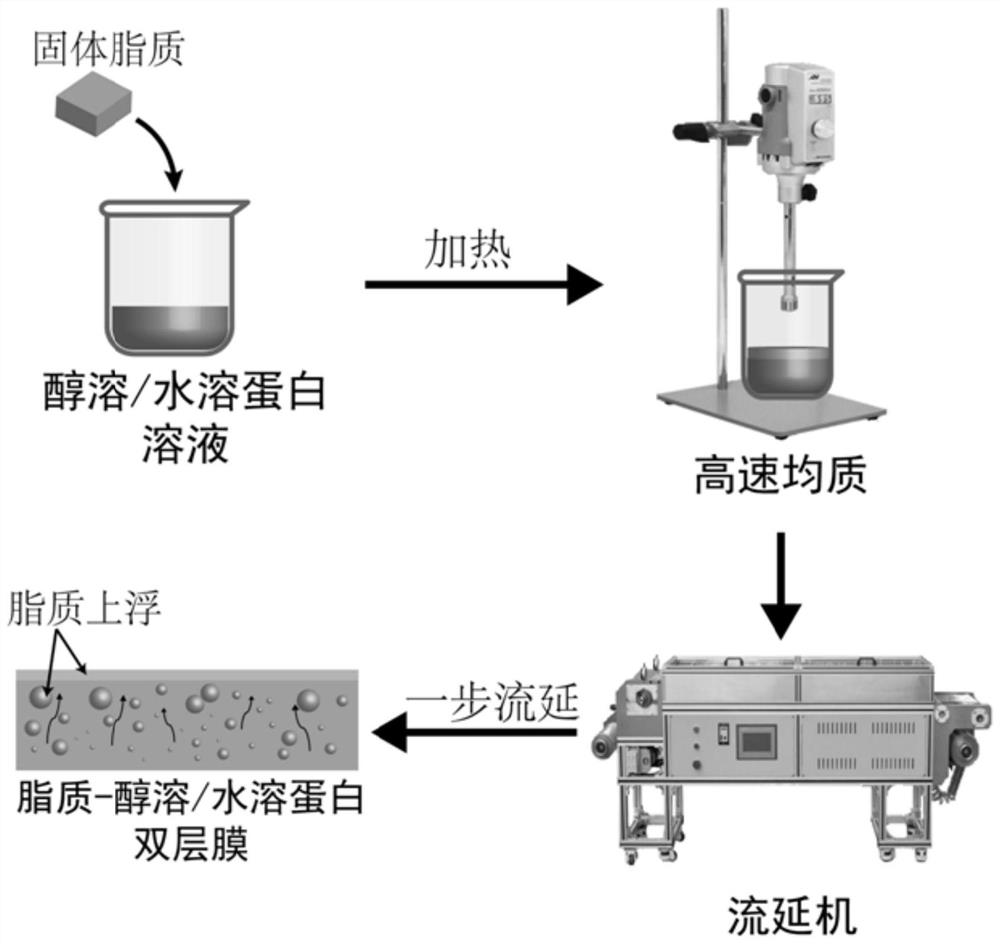

[0049] A kind of lipid-protein edible bilayer active membrane, its preparation process is as follows figure 1 As shown, specifically made by the following steps:

[0050] (1) Preparation of film-forming solution: Dissolve zein and gelatin A in 80% acetic acid-water solution respectively; after stirring until completely dissolved, add oregano essential oil into the zein solution, and continue magnetic stirring for 15 minutes to obtain gliadin solution;

[0051] Add tea polyphenols to the gelatin solution, and continue magnetic stirring for 15 minutes to obtain a water-soluble protein solution;

[0052] Then mix the gliadin solution and the water-soluble protein solution, add glycerin, and continue to stir for 15 minutes;

[0053] Control the total mass concentration of zein and water soluble protein gelatin A to 20wt%, wherein the mass ratio of zein and water soluble protein gelatin A is 1:2; control the mass percentage of oregano essential oil in solid content to 7.5% , tea...

Embodiment 2

[0058] A lipid-protein edible bilayer active film is made by the following steps:

[0059] (1) Preparation of film-forming solution: Dissolve zein and gelatin A in 80% acetic acid-water solution respectively; after stirring until completely dissolved, add oregano essential oil into the zein solution, and continue magnetic stirring for 15 minutes to obtain gliadin solution;

[0060] Add tea polyphenols to the gelatin solution, and continue magnetic stirring for 15 minutes to obtain a water-soluble protein solution;

[0061] Then mix the gliadin solution and the water-soluble protein solution, add glycerin, and continue to stir for 15 minutes;

[0062] Control the total mass concentration of zein and water soluble protein gelatin A to 20wt%, wherein the mass ratio of zein and water soluble protein gelatin A is 1:2; control the mass percentage of oregano essential oil in solid content to 7.5% , tea polyphenols accounts for 7.5% by mass of the solid content; the concentration of...

Embodiment 3

[0067] A lipid-protein edible bilayer active film is made by the following steps:

[0068] (1) Preparation of film-forming solution: Dissolve zein and gelatin A in 80% acetic acid-water solution respectively; after stirring until completely dissolved, add oregano essential oil into the zein solution, and continue magnetic stirring for 15 minutes to obtain gliadin solution;

[0069] Add tea polyphenols to the gelatin solution, and continue magnetic stirring for 15 minutes to obtain a water-soluble protein solution;

[0070] Then mix the gliadin solution and the water-soluble protein solution, add glycerin, and continue to stir for 15 minutes;

[0071] Control the total mass concentration of zein and hydrosoluble protein gelatin A to 20wt%, wherein the mass ratio of zein and hydrosoluble protein gelatin A is 1:1; control the mass percentage of oregano essential oil in solid content to 7.5% , tea polyphenols accounts for 7.5% by mass of the solid content; the concentration of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com