Chemical vapor deposition epitaxy device and method for preparing PVT method AlN seed crystals

A chemical vapor deposition and seed crystal technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve the problems of AlN crystal diameter expansion difficulty, low yield, complex process, etc., and achieve simple structure , low growth temperature, and the effect of accelerating the diameter expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

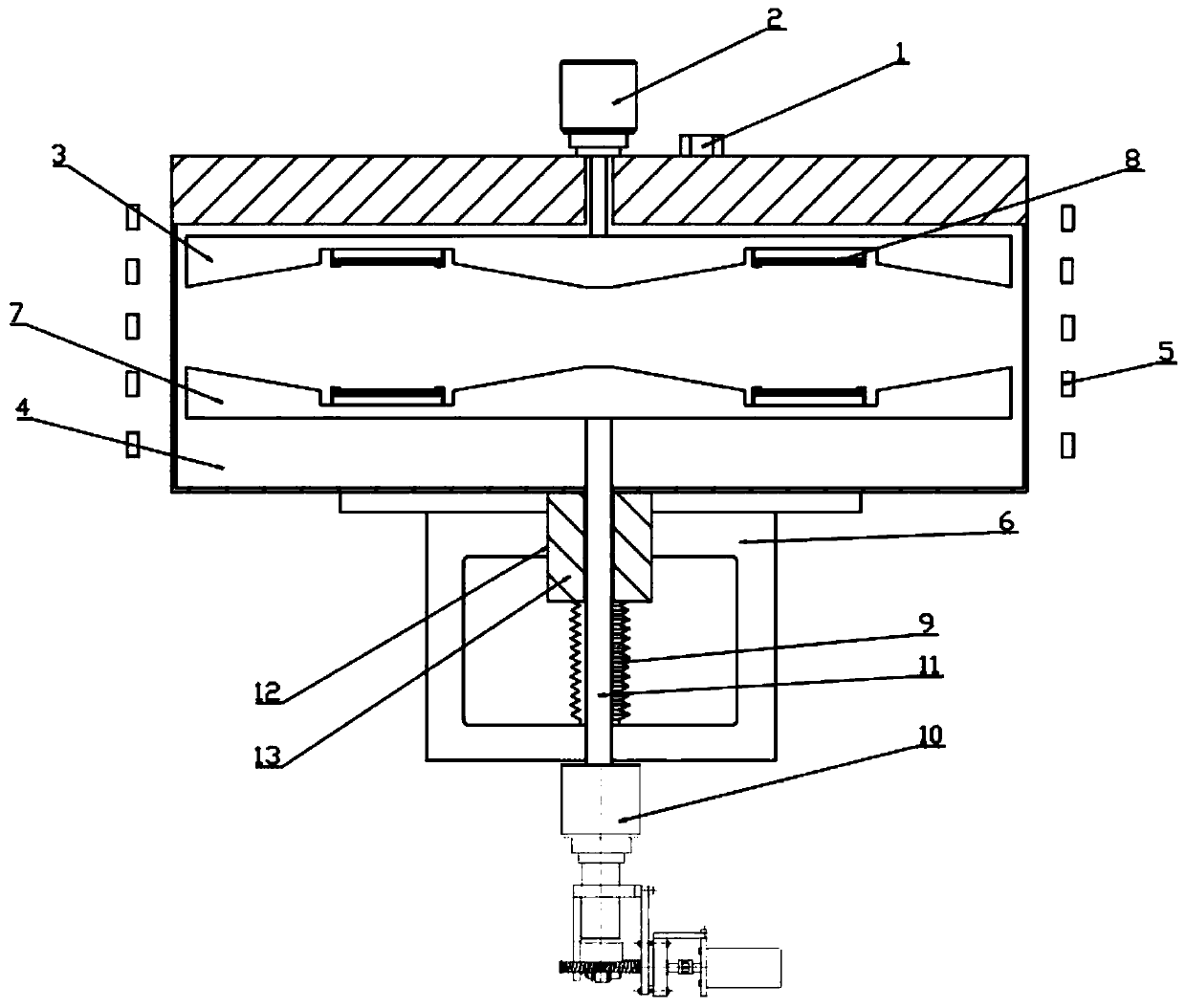

[0046] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a chemical vapor deposition epitaxy device for preparing PVT AlN seed crystals in this embodiment, including an air inlet 1, an upper rotating motor 2, an upper tantalum carbide deflector 3, a housing 4, and a coil 5. Fixed bracket 6, lifting block limit hole 12, lifting block 13, retractable bellows 9, lower tantalum carbide guide table 7, rotating lifting device 10, rotating rod 11 and multiple growing devices 8, the top of the housing 4 There is an air inlet 1, the air inlet 1 communicates with the inside of the housing 4, the upper rotating motor 2 is installed at the center of the top of the housing 4, a fixed bracket 6 is installed at the bottom of the housing 4, and a coil is installed on the outer wall of the housing 4 5. The upper and lower tantalum carbide flow guides 3 and the lower tantalum carbide flow guides 7 are installed symmetrically inside the shell 4, one end of th...

specific Embodiment approach 2

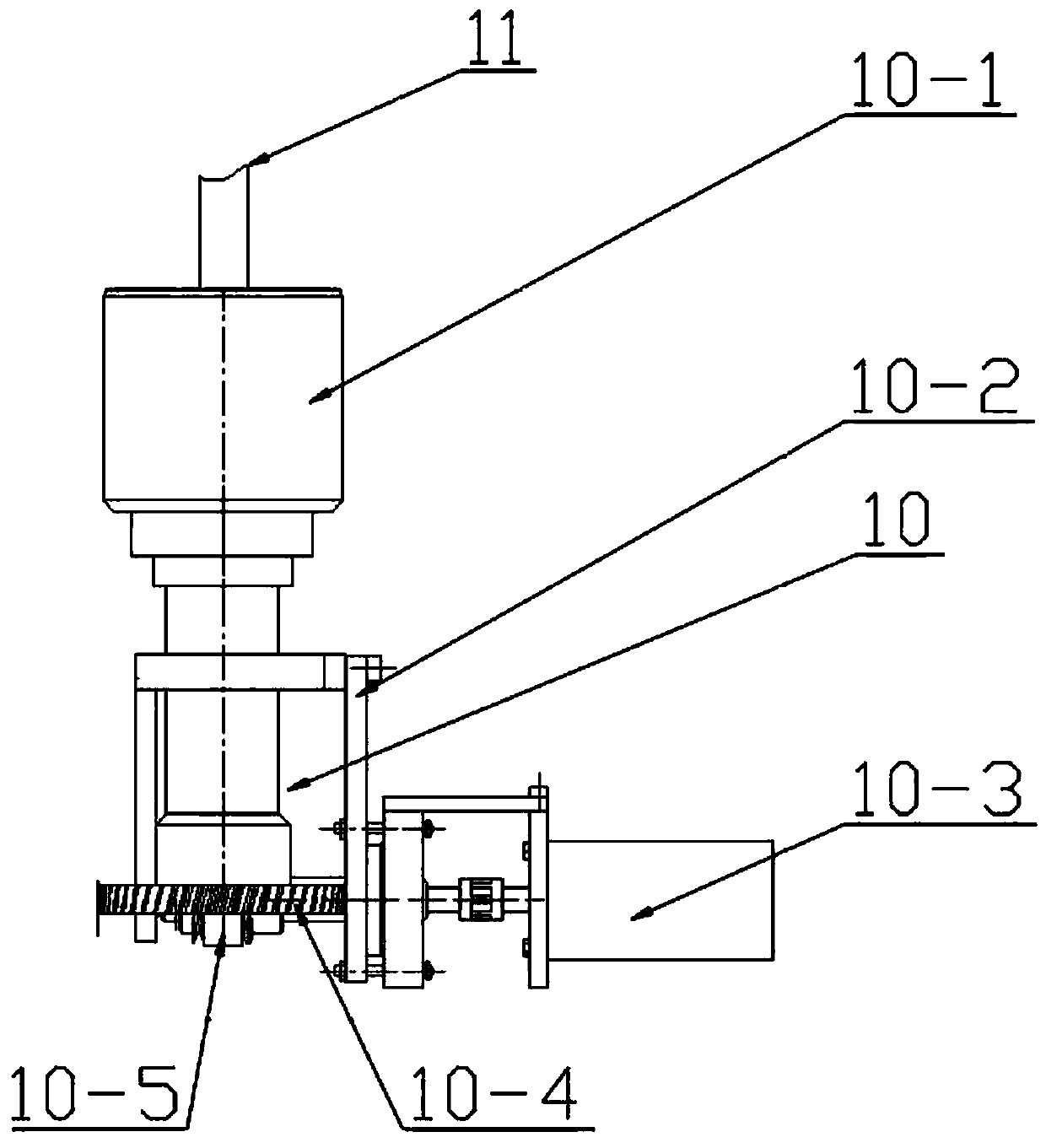

[0047] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, based on specific embodiment 1, a chemical vapor deposition epitaxy device for preparing AlN seed crystals by PVT method in this embodiment, the rotating lifting device 10 includes a lower rotating motor 10-1, a motor fixing frame 10 -2, lifting motor 10-3, worm screw 10-4, worm gear 10-5, the lower end of the lower rotating motor 10-1 is fixedly installed on the motor fixing frame 10-2, and the output end of the lower rotating motor 10-1 is fixedly installed with a worm gear 10 -5, the lifting motor 10-3 is fixedly installed on the motor fixing frame 10-2, the output end of the lifting motor 10-3 is fixedly installed with a worm screw 10-4, the worm screw 10-4 and the worm wheel 10-5 are engaged and installed, and the lower rotating motor 10 The top of -1 is fixedly connected with the rotating rod 11.

specific Embodiment approach 3

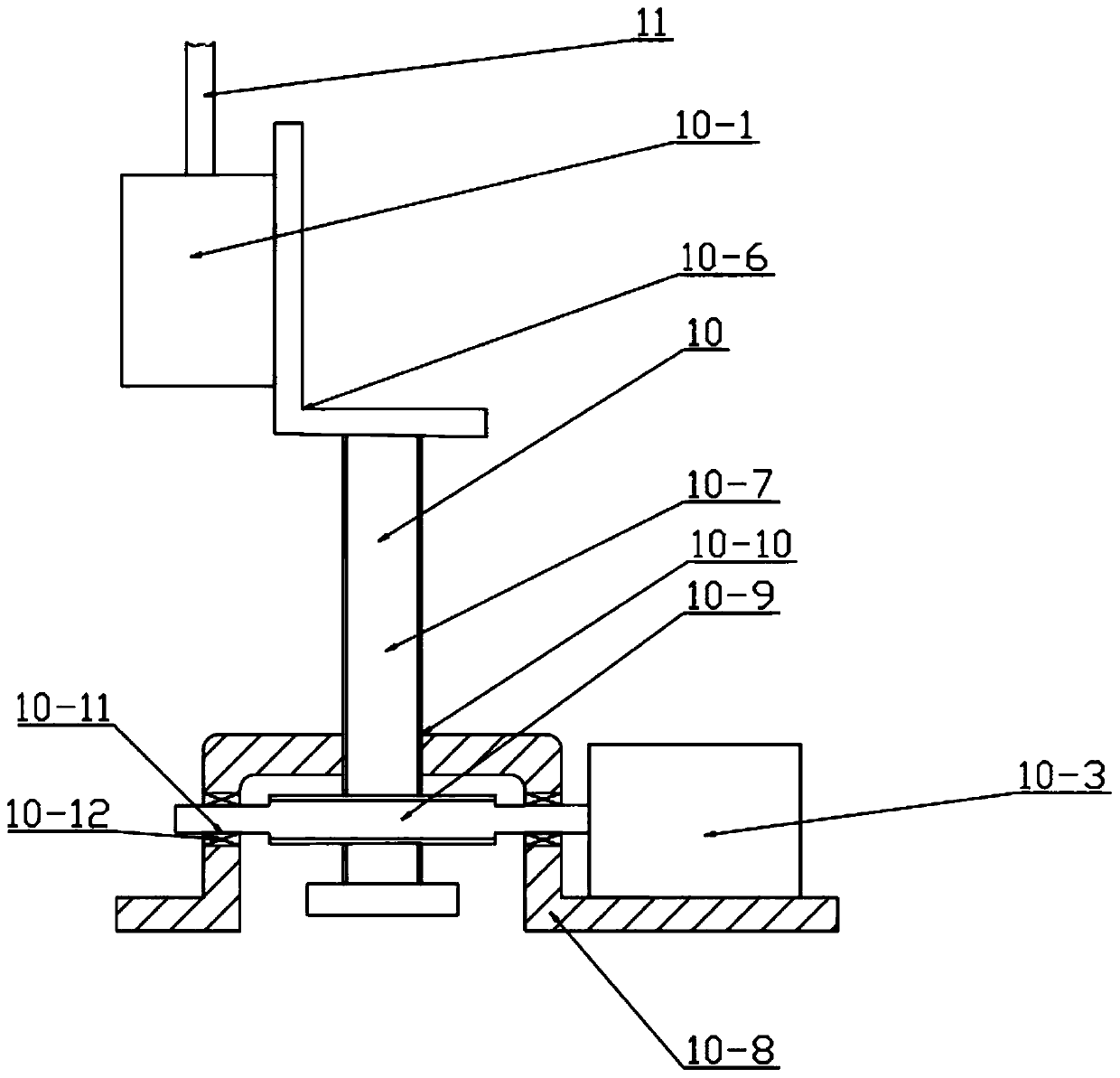

[0048] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, based on specific embodiment 1, a chemical vapor deposition epitaxy device for preparing PVT AlN seed crystals in this embodiment, the rotating lifting device 10 includes a lower rotating motor 10-1, a lifting motor 10- 3. The rotating motor frame 10-6, screw mandrel 10-7, fixed seat 10-8, output worm 10-9 and two bearings 10-12, the top of the fixed seat 10-8 is processed with a first through hole 10-10, The left and right ends of the fixed seat 10-8 are symmetrically processed with second through holes 10-11 respectively, and the lower rotating motor 10-1 is fixedly installed on the rotating motor frame 10-6, and the rotating motor frame 10-6 is fixed to the top of the screw rod 10-7 Install, screw mandrel 10-7 is installed in the first through hole 10-10, and two bearings 10-12 are respectively installed in the second through hole 10-11 that the left and right ends of holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com