Reflective geometric holographic film based on two-dimensional characteristics and preparation method and application thereof

A two-dimensional feature, reflective technology, applied in the field of 3D display, can solve the problems of inability to meet the folding, winding storage, low product yield, difficult processing, etc., to achieve flexible application form, excellent imaging quality, low process cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides a method for preparing the above-mentioned reflective geometric holographic film based on two-dimensional features, including the following steps:

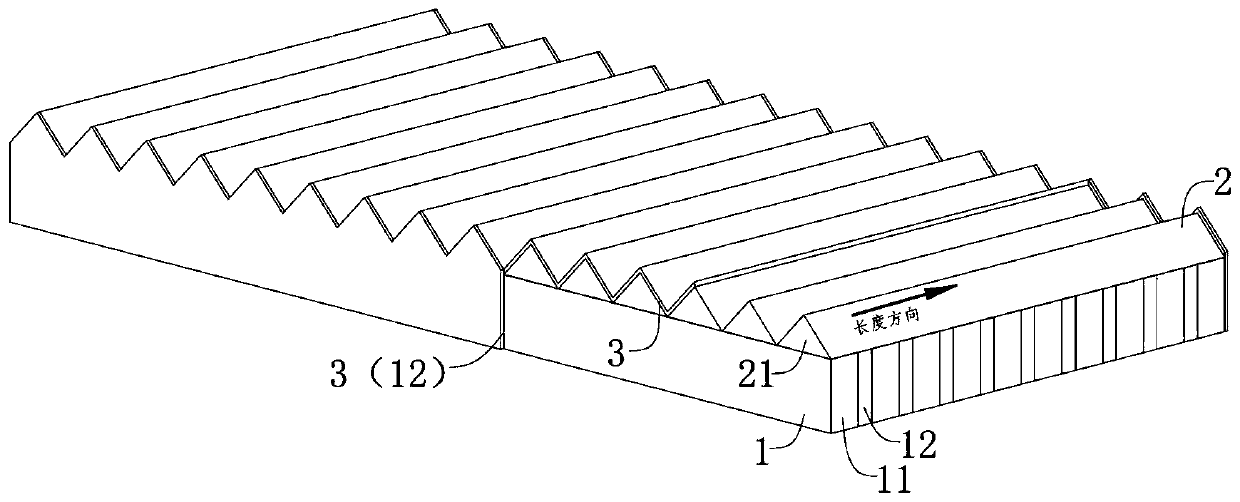

[0074] 1) Prepare a elementary film 1 arranged alternately between the transparent layer 11 and the reflective layer 12 and a transparent film corresponding to the elementary film 1, preferably a flexible holographic elementary film of publication number CN110794504A and its preparation method and application Flexible holographic primitive film;

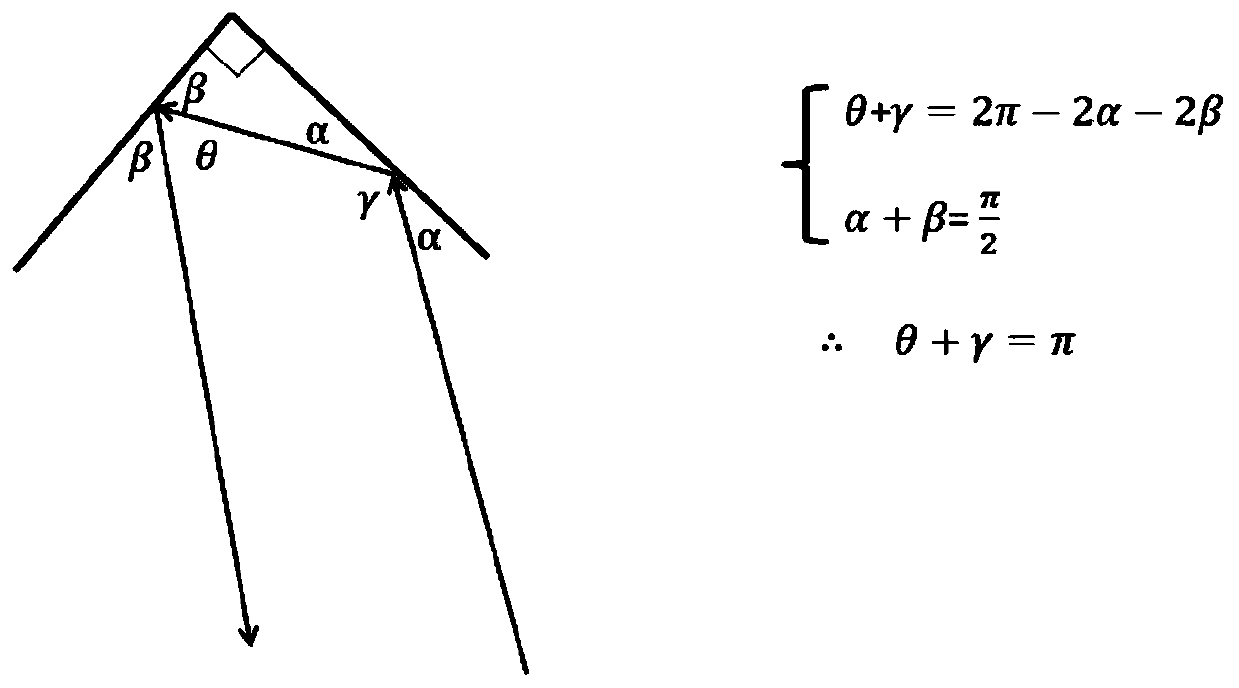

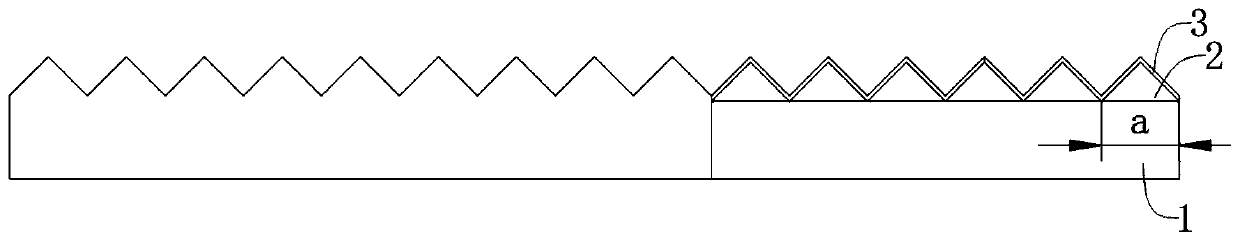

[0075] 2) Adhere the transparent film to the surface of the elementary film 1, and cut the transparent film in the direction perpendicular to the transparent layer 11 and the reflective layer 12 to form one layer of the elementary film and the other layer of the array. A film with an undulating jagged surface formed by the arrangement of columnar elementary prisms 2 with a right triangle in cross section;

[0076] 3) A reflective film 3 is plated on t...

Embodiment 1

[0081] Prepare a rectangular flexible element film 1 with a thickness of 1 mm and a transparent layer 11 and a reflective layer 12 arranged alternately, and a transparent film with a thickness of 1 mm corresponding to the rectangular element film 1, wherein the material of the transparent layer 11 is PC film, the reflective layer 12 is made of aluminum foil reflective film, and the transparent film is PC film;

[0082] Adhere the transparent film to the surface of the elementary film 1, and then cut the transparent film in the direction perpendicular to the transparent layer 11 and the reflective layer 12. The cross-section of the scrap is 1 mm high isosceles right-angled triangular prism. After cutting Obtain a number of columnar elementary prisms 2 with a cross-section of 1mm high isosceles right-angled triangles arrayed on the surface of the elementary film 1 with undulating and jagged films; then a reflective film 3 is plated on the end surface of the film and the inclined sur...

Embodiment 2

[0085] Prepare a rectangular flexible element film 1 with a thickness of 0.5 mm and a transparent layer 11 and a reflective layer 12 arranged alternately and a transparent film with a thickness of 1 mm corresponding to the rectangular element film 1, wherein the material of the transparent layer 11 is PC film, the reflective layer 12 is made of aluminum foil reflective film, and the transparent film is PC film;

[0086] The transparent film is adhered to the surface of the elementary film 1, and then the transparent film is cut in the direction perpendicular to the transparent layer 11 and the reflective layer 12, and the cross-section of the scrap is 0.5 mm high isosceles right-angled triangular prism. After cutting Obtain a number of columnar elementary prisms 2 with a cross section of 0.5 mm high isosceles right-angled triangles arrayed on the surface of the elementary film 1 with undulating and jagged films; then a reflective film 3 is plated on the end surface of the film and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com