Wheeled engineering machinery automatic tracking driving control system and method

A construction machinery and automatic tracking technology, applied in control/regulation systems, non-electric variable control, two-dimensional position/channel control, etc., can solve problems such as poor results, and achieve universality and universality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

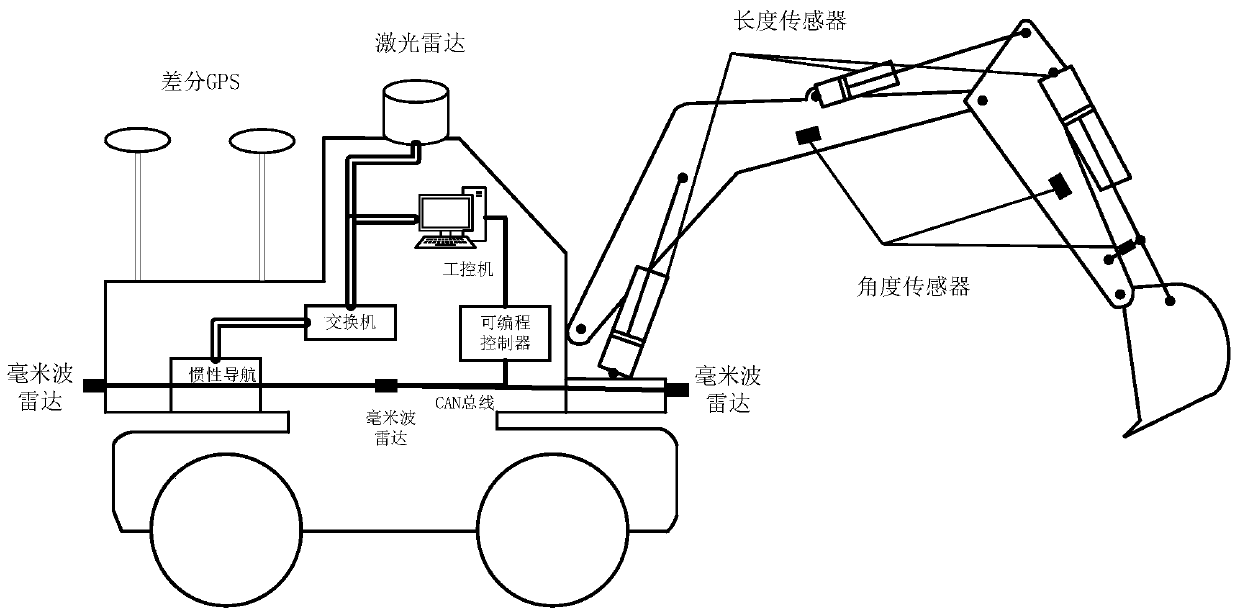

[0040] In the specific embodiment of the present invention, it is divided into a hardware level and a software level. At the hardware level, it includes a wheeled excavator, and the wheeled excavator is equipped with a variety of sensor devices, using a variety of sensor fusion solutions to achieve multiple specific functions. These devices include: 32-line lidar (an example of multi-line lidar), millimeter-wave radar, differential GPS, inertial navigation, industrial computer, CAN bus, etc.

[0041] Taking a wheeled excavator as an example, the sensor layout is as follows, for details, please refer to figure 1 .

[0042] (1) Install on the top of the cab of the wheeled excavator: 32-line laser radar (an example of multi-line laser radar);

[0043] (2) Installed directly in front of the wheeled excavator: millimeter wave radar;

[0044] (3) Install symmetrically on both sides of the wheeled excavator body: millimeter wave radar;

[0045] (4) Installed behind the wheeled ex...

Embodiment 2

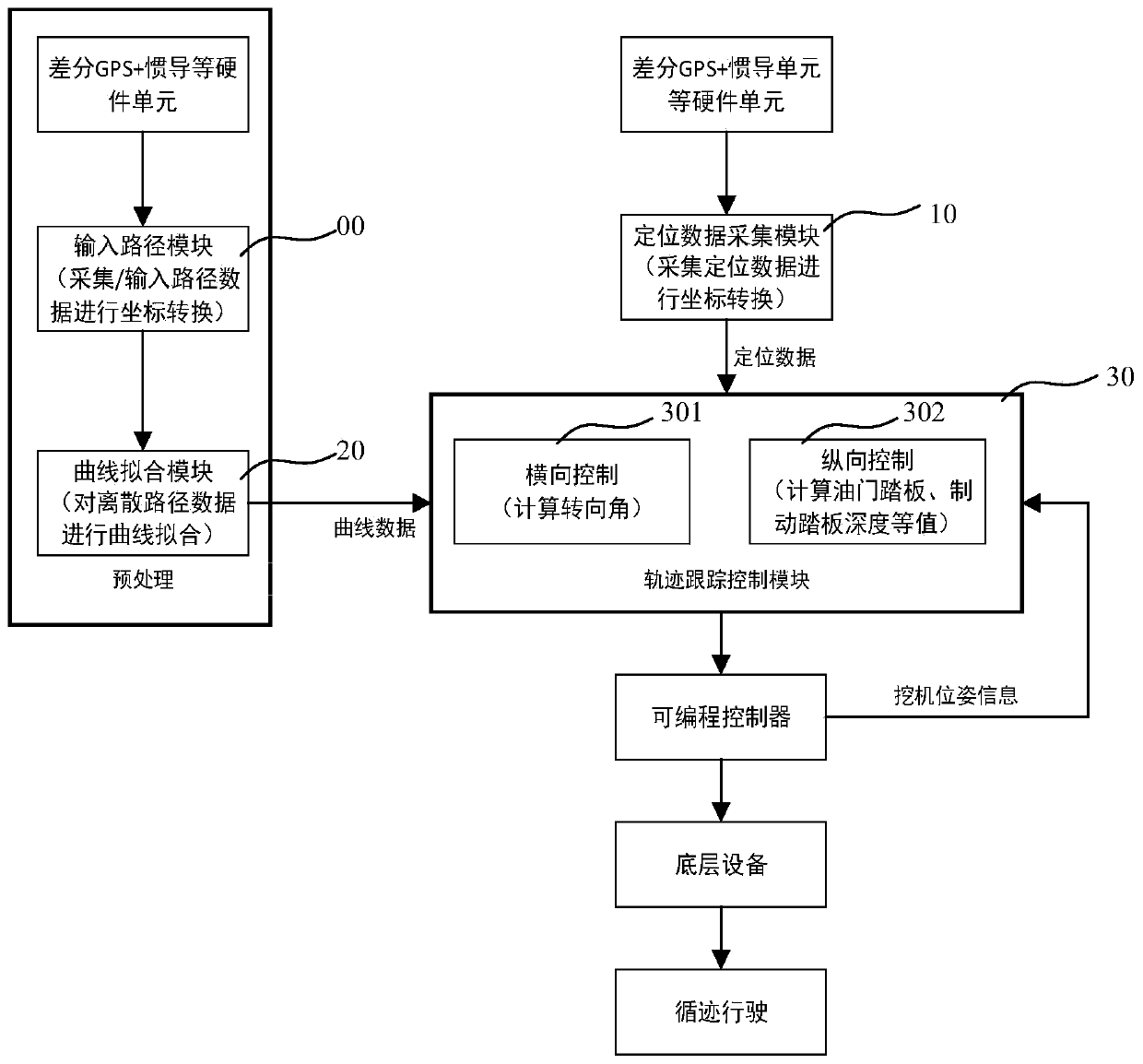

[0089] Such as figure 2 As shown, a wheeled construction machinery automatic tracking driving control method, including:

[0090] The first is preprocessing:

[0091] 1) First, two methods are used to obtain path data, which can be obtained from the dispatching system through the path input module, or information such as the coordinates of the wheeled excavator’s travel path can be sent to the industrial computer through the GPS antenna and inertial navigation hardware, and the positioning The data collection module 10 collects, thereby obtains the path data under the geographic coordinate system;

[0092] 2) Afterwards, the positioning data acquisition module 10 will obtain the path data for analysis and coordinate transformation, mainly through the Gaussian forward formula to convert the X-axis pointing to the east, the Y-axis pointing to the north, and the origin at the center of mass of the sensor. Cartesian coordinate system data, and then These transformed path data a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com