Cooling and heating dual-purpose intercooler, fuel cell system and control method

A fuel cell system and cooler technology, which is used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., to achieve the effect of facilitating power adjustment, easy realization, and meeting objective needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

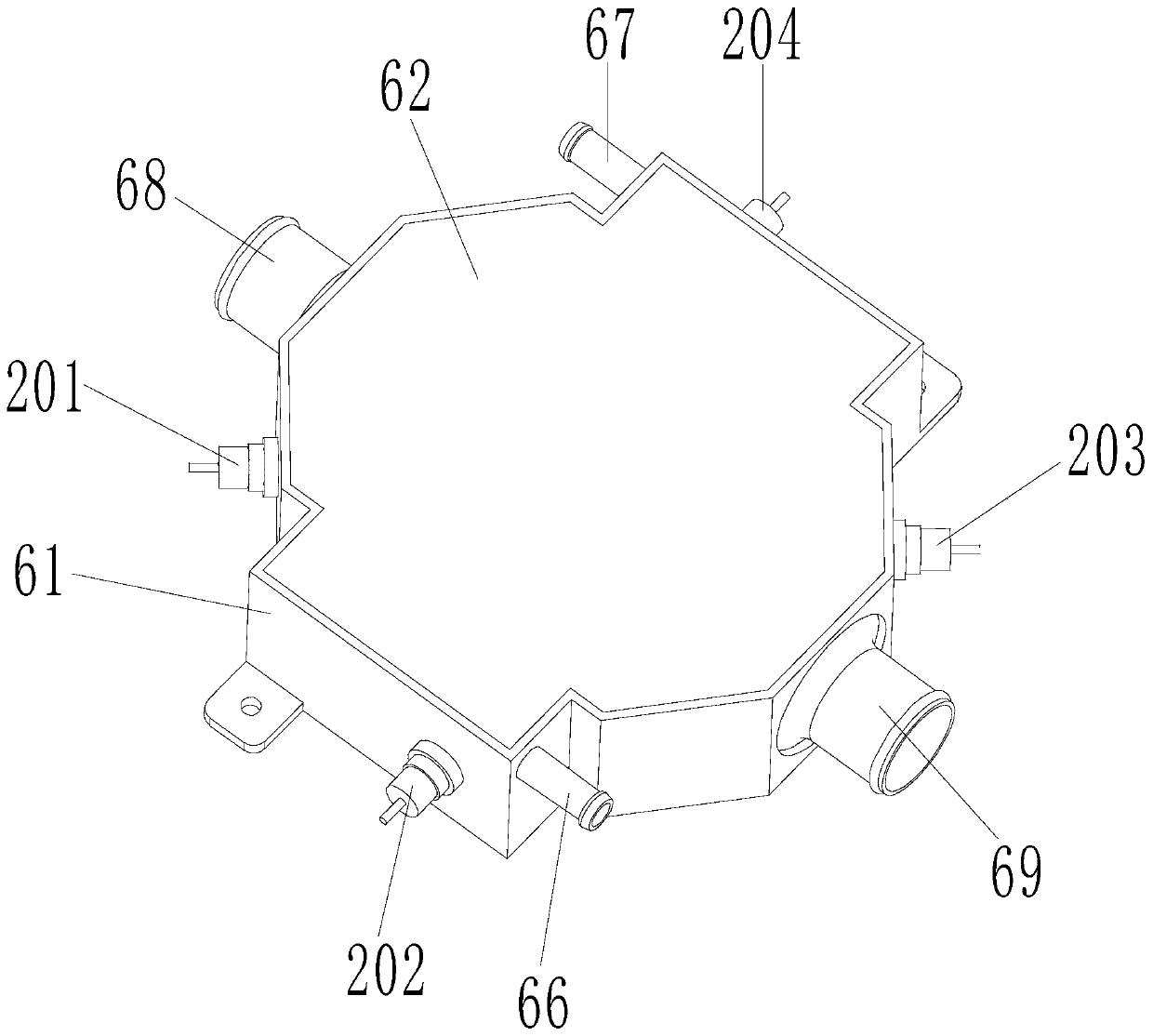

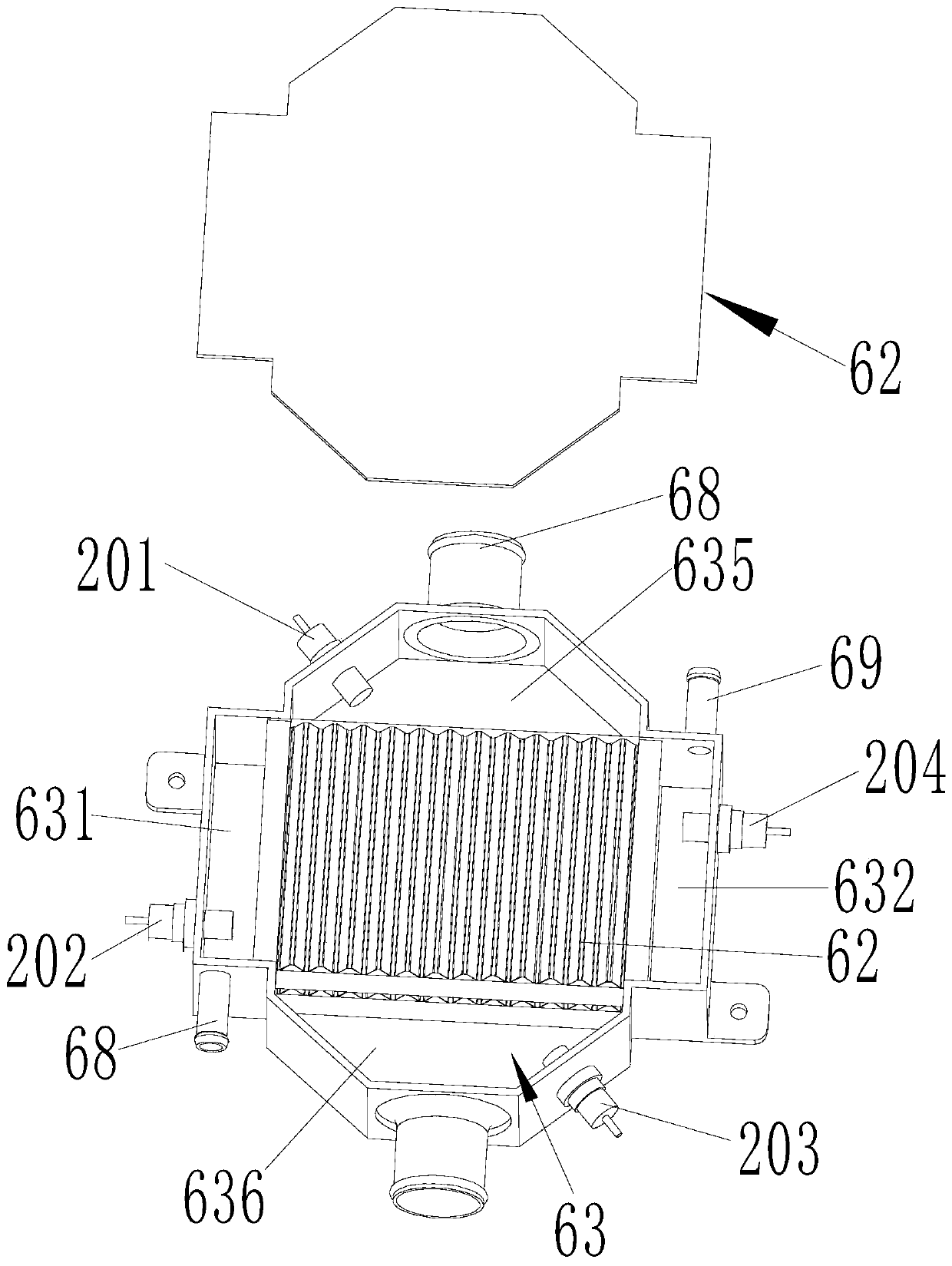

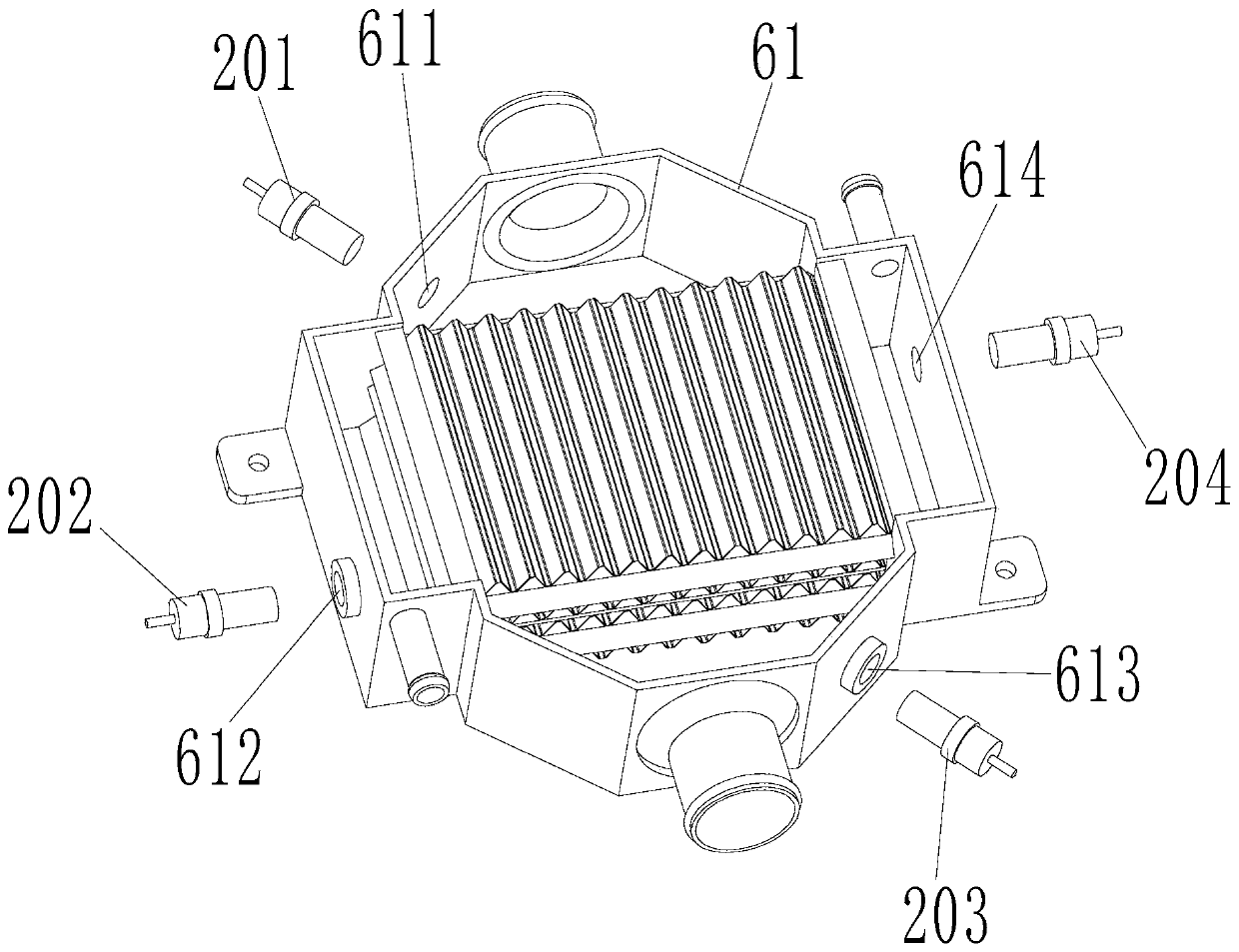

[0036] Such as Figure 1 to Figure 7 As shown, this embodiment provides a dual-purpose intercooler for cooling and heating, including a housing 61 and a cover plate 62, the housing 61 is provided with a cavity 63, and the cover plate 62 is installed at the mouth of the cavity 63, A heating device 64 and a heat exchange device 65 are installed in the cavity 63, and a cooling liquid inlet 66 and a cooling liquid outlet 67 are provided on the housing 61, and the cooling liquid enters the inside of the housing 61 through the cooling liquid inlet 66 to exchange heat with the heating device 64 The device 65 flows out from the coolant outlet 67 after exchanging heat; the housing 61 is also provided with an air inlet 68 and an air outlet 69, and the air enters the inside of the housing 61 from the air inlet 68 and exchanges heat with the heat exchange device 65 from the air. The outlet 69 is discharged, and it is characterized in that: several temperature sensors 200 are also provided...

Embodiment 2

[0045] Such as Figure 8 and Figure 9 As shown, this embodiment is a fuel cell system, including an air filter 1, an air flow meter 2, an air compressor 3, an air compressor controller 4, an intercooler for cooling and heating, a humidifier 7, and a fuel cell The battery cell stack module 8, the coolant circulation system 10 and the fuel cell system controller 300 are characterized in that the dual-purpose intercooler for cooling and heating is the dual-purpose intercooler for cooling and heating described in Embodiment 1, and the air passes through The air filter 1 and the air flow meter 2 enter the air compressor 3, and the air compressor controller 4 controls the air compressor 3 to compress the incoming air and enter the casing from the air inlet 68 of the dual-purpose intercooler for cooling and heating In 61, after heating or cooling in the dual-purpose intercooler for cooling and heating, the air is sent to the humidifier 7 through the air outlet 69, and the humidifie...

Embodiment 3

[0048] Such as Figure 8 and Figure 9 As shown, a fuel cell system control method is characterized in that: the fuel cell system is the fuel cell system described in Embodiment 2, the fuel cell stack module 8 is controlled by the fuel cell system controller 300, and the first temperature sensor 201 detects the air temperature at the air inlet 68, the first temperature sensor 201 transmits the detected temperature signal to the fuel cell system controller 300, the air enters the air compressor 3 after passing through the air filter 1 and the air flow meter 2, and the air The compressor 3 sends compressed air to the dual-purpose intercooler for cooling and heating. When the first temperature sensor 201 detects that the air is lower than a certain set temperature value T1, the fuel cell system controller 300 controls the intercooler for dual-purpose cooling and heating. The heating function of the heating device 64 is turned on to heat the coolant entering the dual-purpose inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com