Methanol waste gas treatment device and treatment method thereof

A treatment device, methanol technology, applied in the field of methanol waste gas treatment devices, can solve the problems of increasing the burden on the wastewater treatment system, increasing the cost of methanol waste gas treatment, and failing to meet the requirements of environmental protection, so as to reduce energy consumption, simplify costs, and save The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

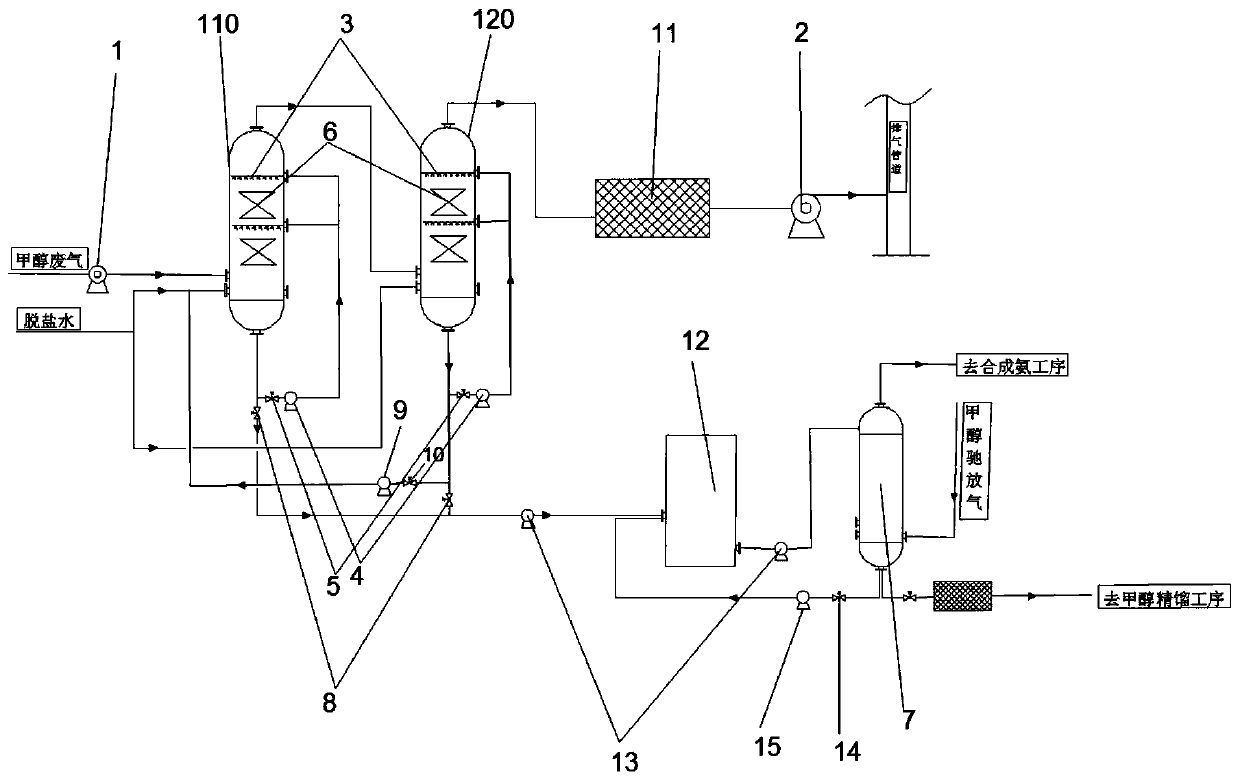

[0036] This embodiment provides a treatment device for methanol waste gas, please refer to figure 1 As shown, in this embodiment, the methanol waste gas treatment device includes an absorption tower group, the intake end of the absorption tower group is connected with the first fan 1, and the first fan 1 is used to suck the methanol waste gas in the factory area into the absorption tower group.

[0037] The exhaust end of the absorption tower group is connected with the exhaust pipe through the second fan 2, and the absorption tower group is used to treat methanol waste gas in the factory area. The second blower 2 has low energy consumption, and can smoothly lead out the methanol waste gas in the factory area after absorbing methanol, thereby reducing the power consumption of the treatment device. After the absorption tower group treats the methanol waste gas in the factory area, the methanol content in the methanol waste gas in the factory area reaches the environmental prote...

Embodiment 2

[0044] This embodiment is further improved on the basis of Embodiment 1, and the difference between this embodiment and Embodiment 1 is as follows:

[0045] Such as figure 1 As shown, the pipeline between the absorption tower group and the exhaust pipeline is also provided with a first filter 11, and the first filter 11 can filter and remove water from the discharged methanol waste gas in the factory area after absorbing methanol, reducing the second-stage Operational risk of wind turbines.

[0046] Such as figure 1 As shown, the treatment effect of methanol purge gas in the alcohol washing tower 7 is ensured, and the water-containing desalted water in the absorption tower group is conveniently discharged from the alcohol-containing water storage tank 12, or the alcohol-containing desalted water in the alcohol-containing water storage tank 12 is discharged Discharged into the alcohol washing tower 7, the third water pump 13 is respectively arranged on the liquid inlet pipe a...

Embodiment 3

[0049] This embodiment provides a treatment method applied to the methanol waste gas treatment device of Embodiment 1 and Embodiment 2, including the following steps:

[0050] Step 1: Methanol waste gas in the factory area is sucked into the first absorption tower 110 of the absorption tower group through the first fan 1, and the desalted water is passed into the first absorption tower 110 and the second absorption tower 120 of the absorption tower group at the same time, and passed through the second water pump 9 Make the desalted water pass through the spray device 3 and circulate and absorb the methanol in the methanol waste gas of the factory area in the absorption tower;

[0051] Step 2: After primary absorption of the methanol waste gas in the factory area in the first absorption tower 110, the discharged waste gas enters the second absorption tower 120 for secondary absorption, and the absorbed methanol waste gas of the factory area is exhausted from the second absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com