Automatic feeding mechanism for full-automatic labelling machine

An automatic feeding and labeling machine technology, applied in the directions of labeling machines, labels, dryers, etc., can solve the problems of inability to achieve automatic feeding, not meeting development needs, and procrastinating equipment efficiency, and improve positioning accuracy. and stability, avoid overshoot, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The automatic feeding mechanism of the present invention will be described in detail in combination with the fully automatic four-station labeling machine. The description is as follows:

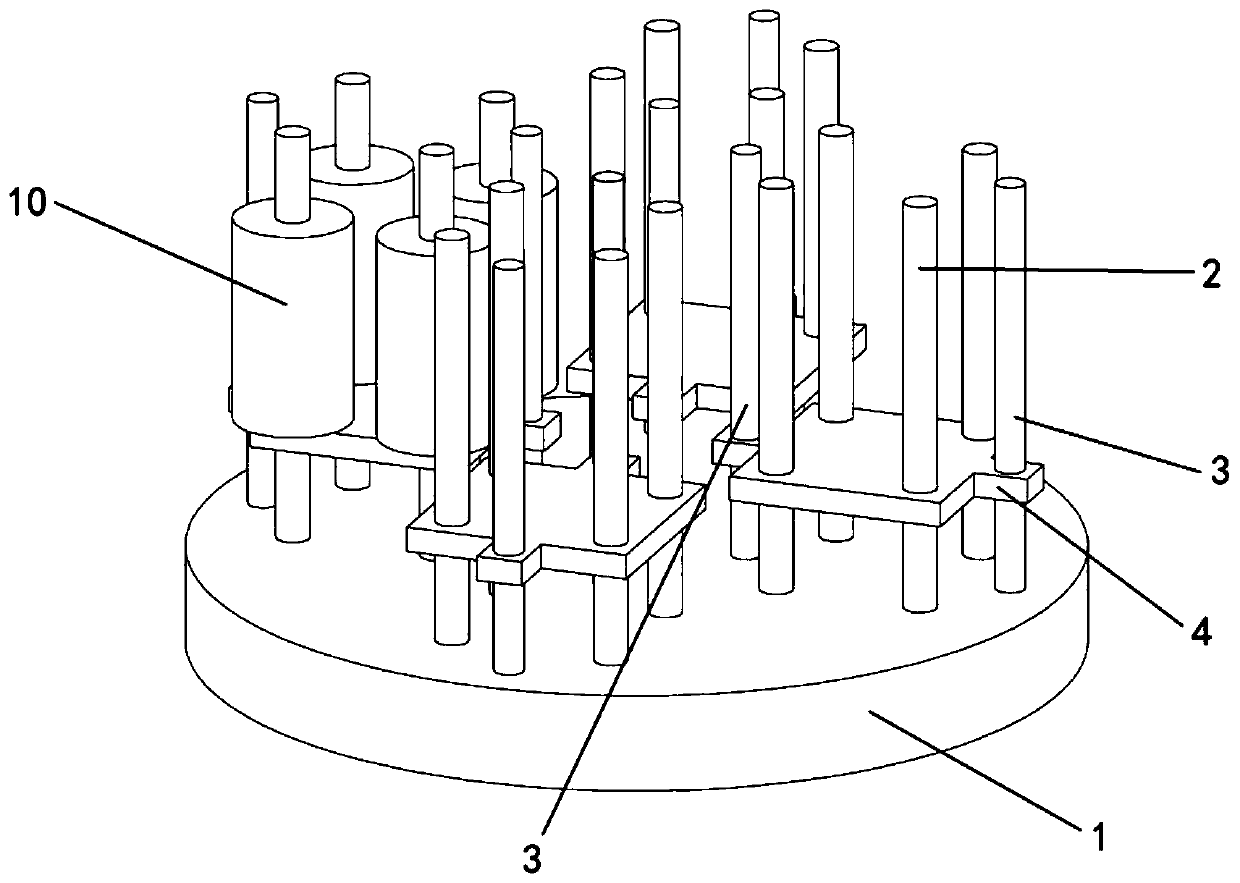

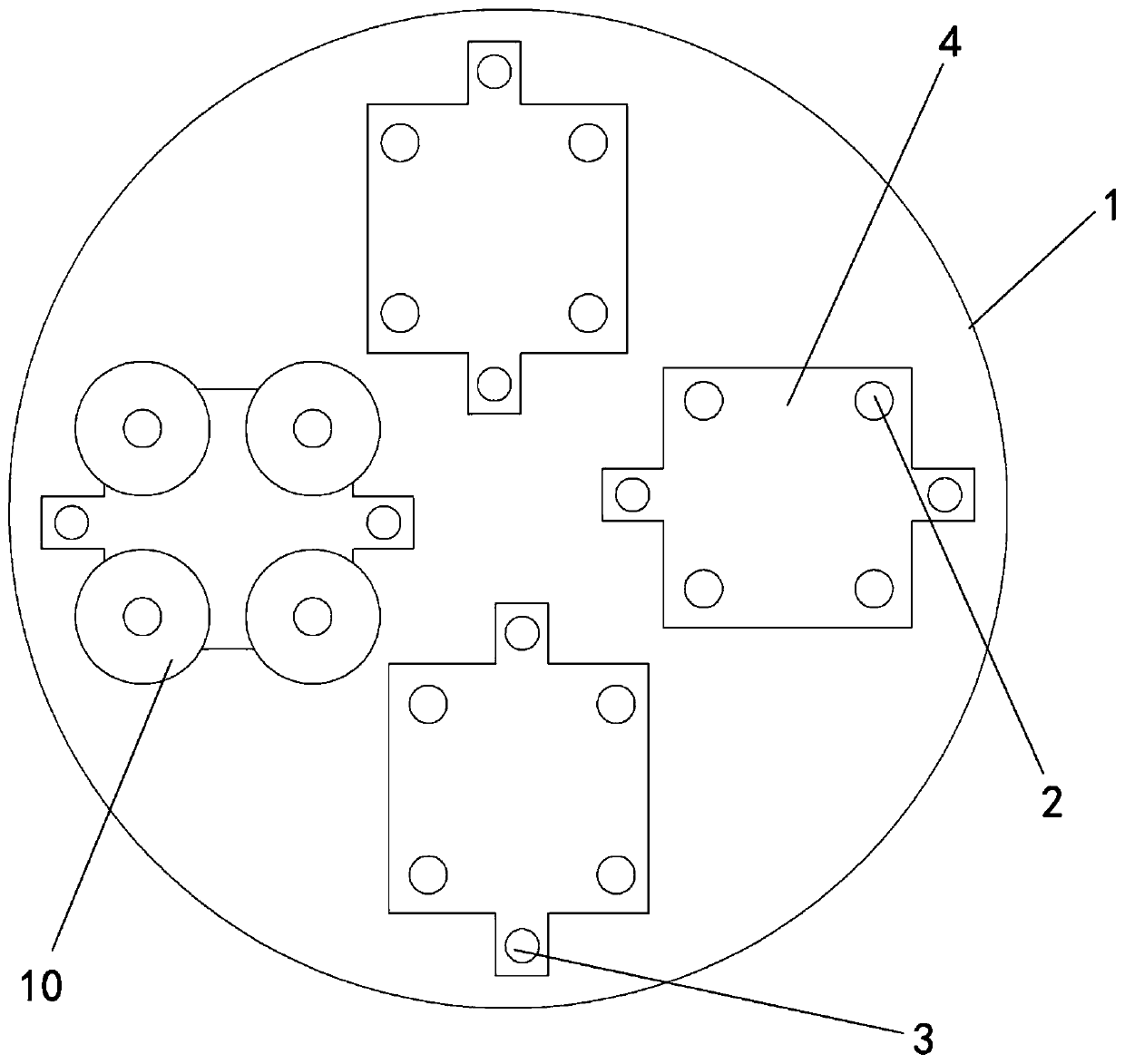

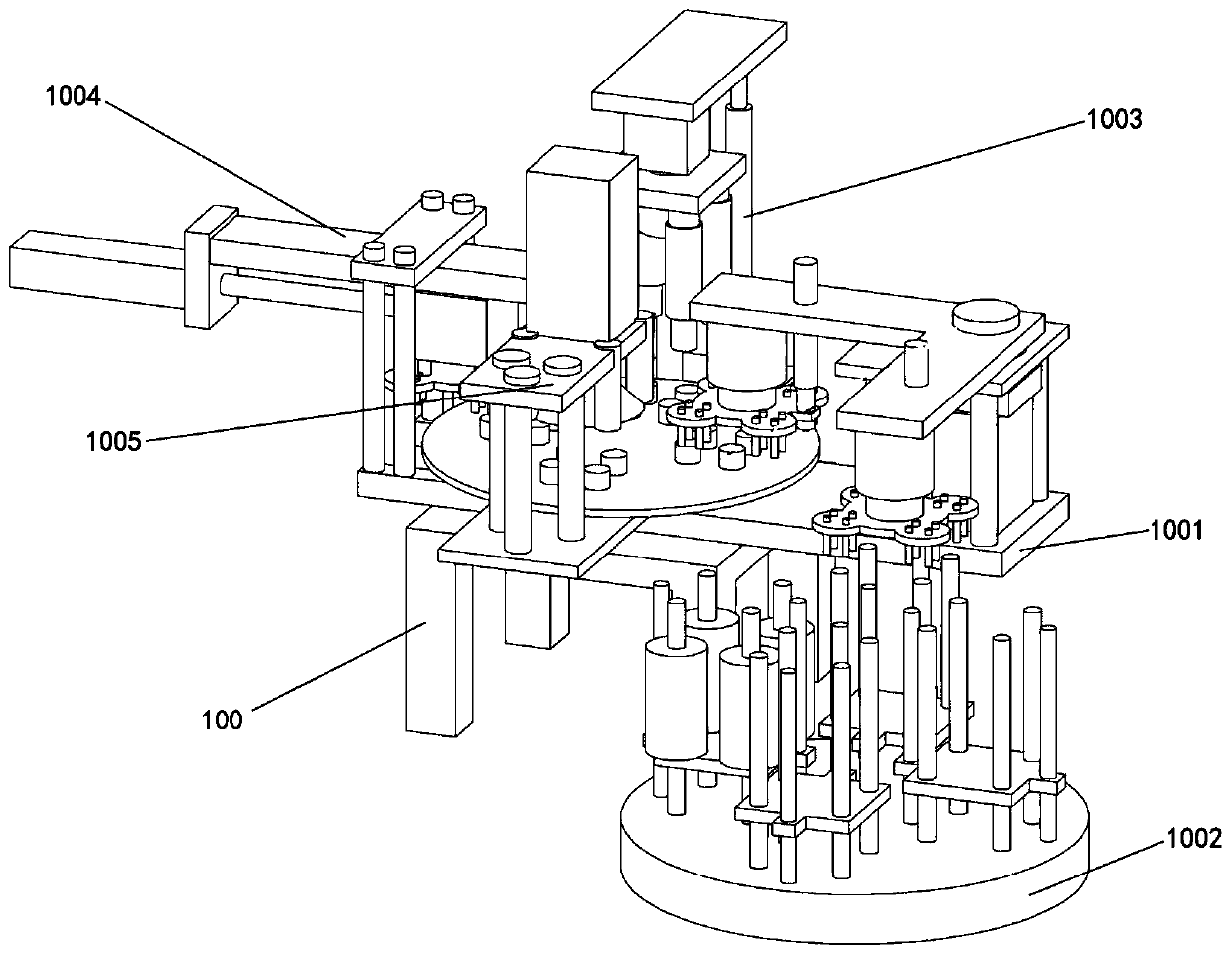

[0031] A fully automatic four-station labeling machine includes a fixed bracket 100, a first support frame is arranged on the upper right of the fixed frame 100, and a 90° manipulator mechanism 1001 is arranged on the upper end of the first support frame; the fixed bracket A second support frame is provided on the upper left side of 100, and a glue dispensing mechanism 1003 is provided on the upper end of the second support frame; a third support frame is provided on the lower left side of the fixed support 100, and a third support frame is provided above the third support frame. Labeling mechanism 1004; a fourth support frame is provided at the lower right of the fixed support 100, and a heating mechanism is provided above the fourth support frame; further including a feeding mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com