Controllable processing method and device for nanopore array based on optical control

A nano-hole array, optical manipulation technology, applied in the process of producing decorative surface effects, micro-structure devices, manufacturing micro-structure devices, etc., can solve the application space limitation, dependence, uniformity and consistency requirements of gold nano-particle arrays Very high and other problems, to achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] The controllable processing method of the nanohole array based on optical manipulation in this embodiment includes the following steps:

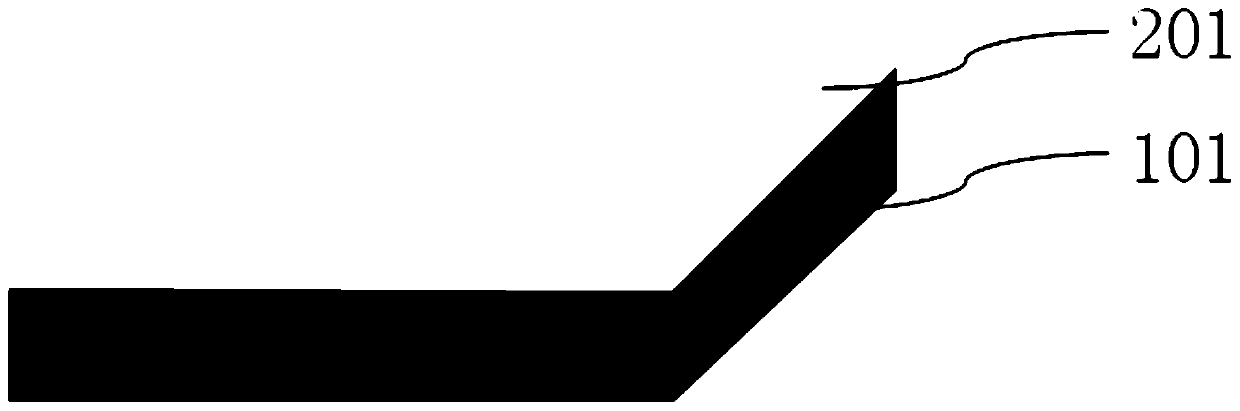

[0031] Step (1), such as figure 1 As shown, spin-coat one layer of cetyltrimethylammonium chloride layer 201 on the upper surface of the cleaned silicon wafer 101;

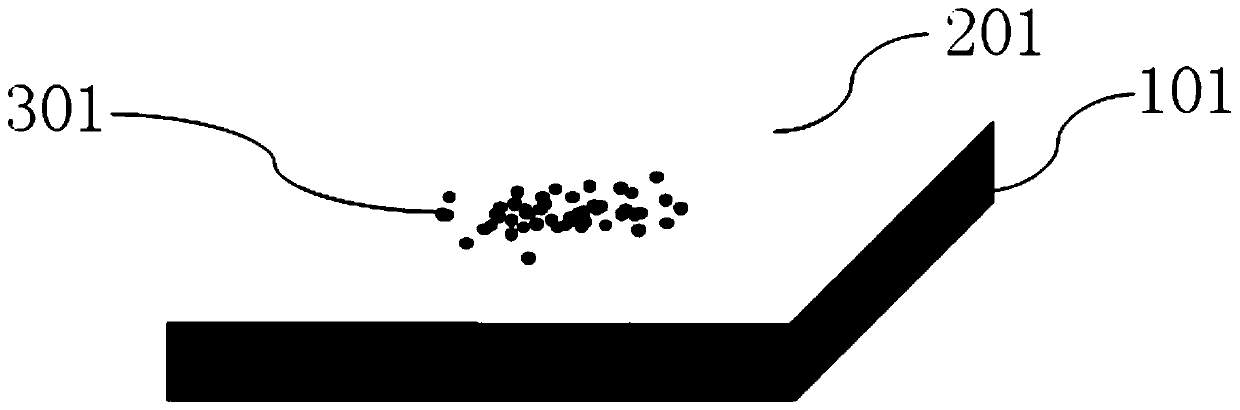

[0032] Step (2), such as figure 2 As shown, a layer of gold nanoparticles 301 is self-assembled on the upper surface of the silicon wafer 101 after step (1), and a disordered gold nanoparticle array 404 is formed on the silicon wafer 101;

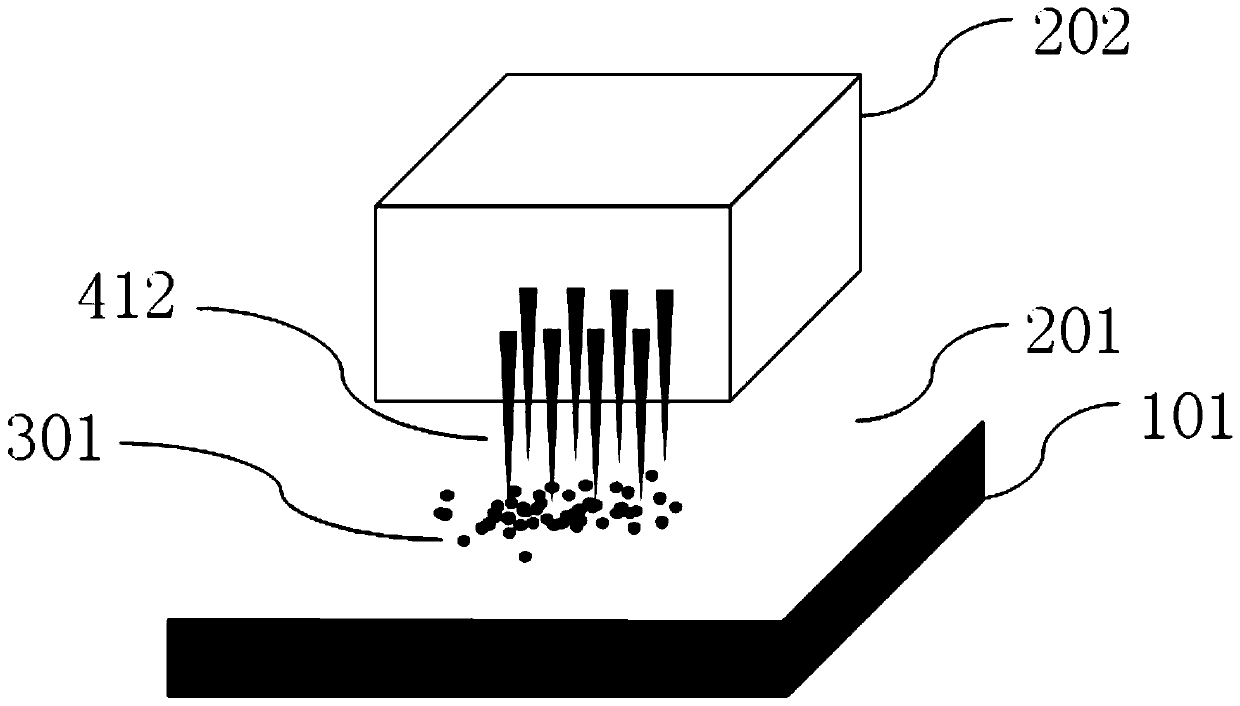

[0033] Step (3), such as image 3 As shown, the array laser beam 412 is dispersed by the multi-beam galvanometer 202, and the array laser beam 412 disperses the gold nanoparticles 301 in the disordered gold nanoparticle array 404 of step (2), as Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com