Transmission electron microscope in-situ electrothermal coupling chip and preparation method thereof

A technology of electrothermal coupling and transmission electron microscopy, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as electrical conductivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] Example 1: Preparation of in-situ electrothermal coupling chip for transmission electron microscopy

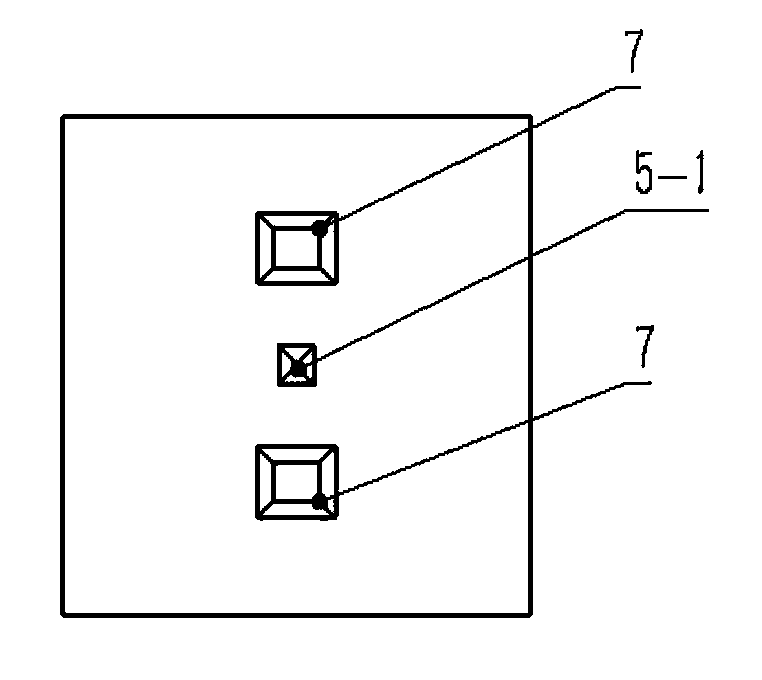

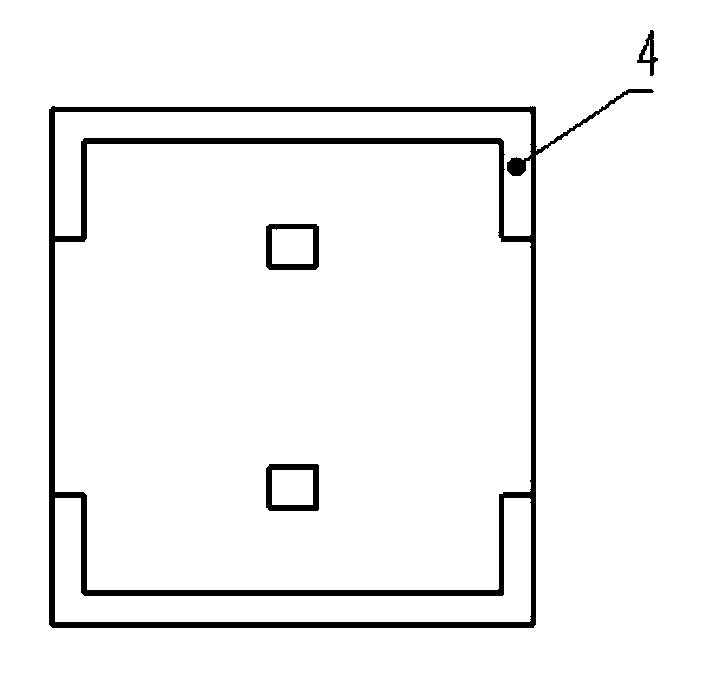

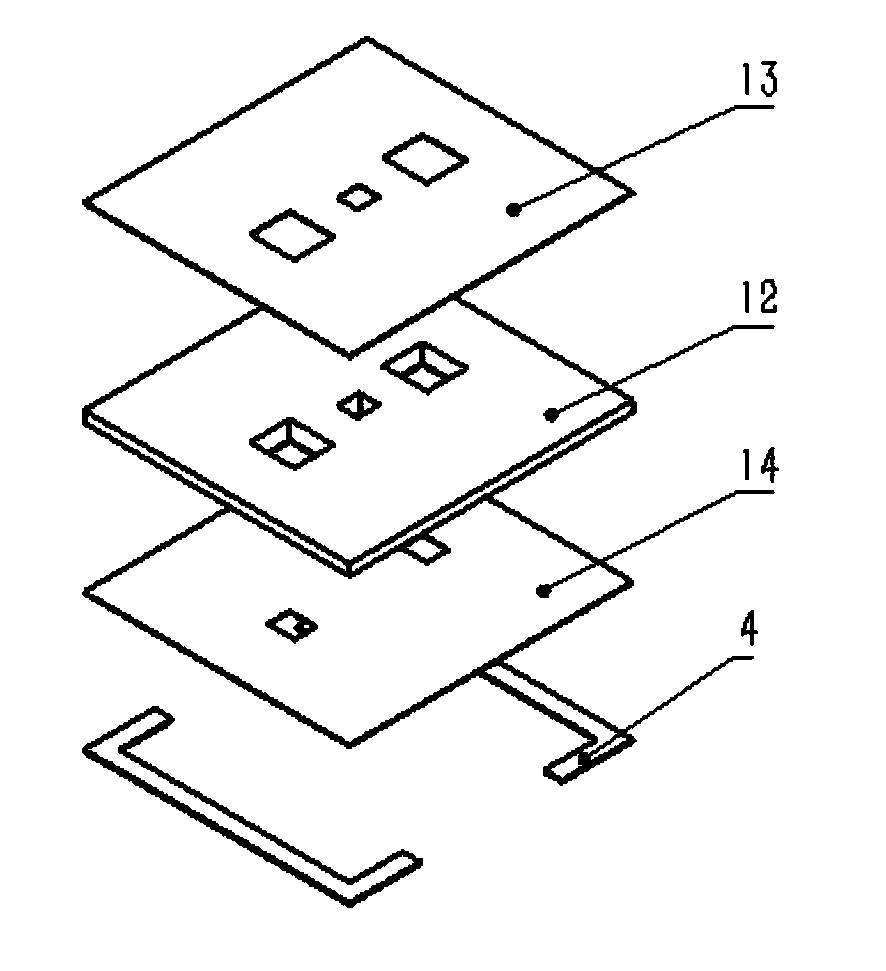

[0140] according to Figure 1-Figure 8 structure, the fabrication of the following chip was carried out. Among them, 1 is the in-situ electrothermal coupling chip of the transmission electron microscope; 2 is the top piece; 3 is the bottom piece; 4 is the metal bonding layer; 5 is the center window; 5-1 is the center window of the top piece; 5-2 is the center window of the bottom piece ; 7 is a sample injection port; 8 is a heating layer; 9 is a heating wire; 10 is the central area of the heating wire; 11 is four contact electrodes (for heating); 12 is a silicon substrate; 13 is silicon nitride or silicon oxide Layer 1; 14 is a silicon nitride or silicon oxide layer 1'; 15 is an electrode material layer; 15-1 is a working electrode; 15-2 is a reference electrode; 15-3 is a counter electrode; 16 is a transition layer; 17 is Insulation layer; 18 is silicon nitride or ...

Embodiment 2

[0165] The gold nanoparticle colloidal solution sample is injected into the central window through the sample injection port of the in-situ electrothermal coupling chip of the transmission electron microscope obtained in Example 1, and put into the transmission electron microscope after packaging for observation. It is found that after the heating wire is heated, the nanometer particles can It is stable for a long time, and the shooting picture is very stable when heated in the electron microscope, which shows that the drift rate of the in-situ electrothermal coupling chip for the transmission electron microscope of the present invention is low.

Embodiment 3

[0167] The platinum nanoparticles were injected into the central window through the sample injection port of the in-situ electrothermal coupling chip obtained in Example 1, packaged and put into the transmission electron microscope for observation, and it was found that the two-dimensional arrangement of the atomic structure of the nanoparticles could be clearly seen. The lattice fringes indicate that the imaging resolution of the in-situ electrothermal coupling chip of the transmission electron microscope of the present invention can reach atomic-level resolution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com