Gly-Ni-dobdc adsorbent, and preparation method and application thereof

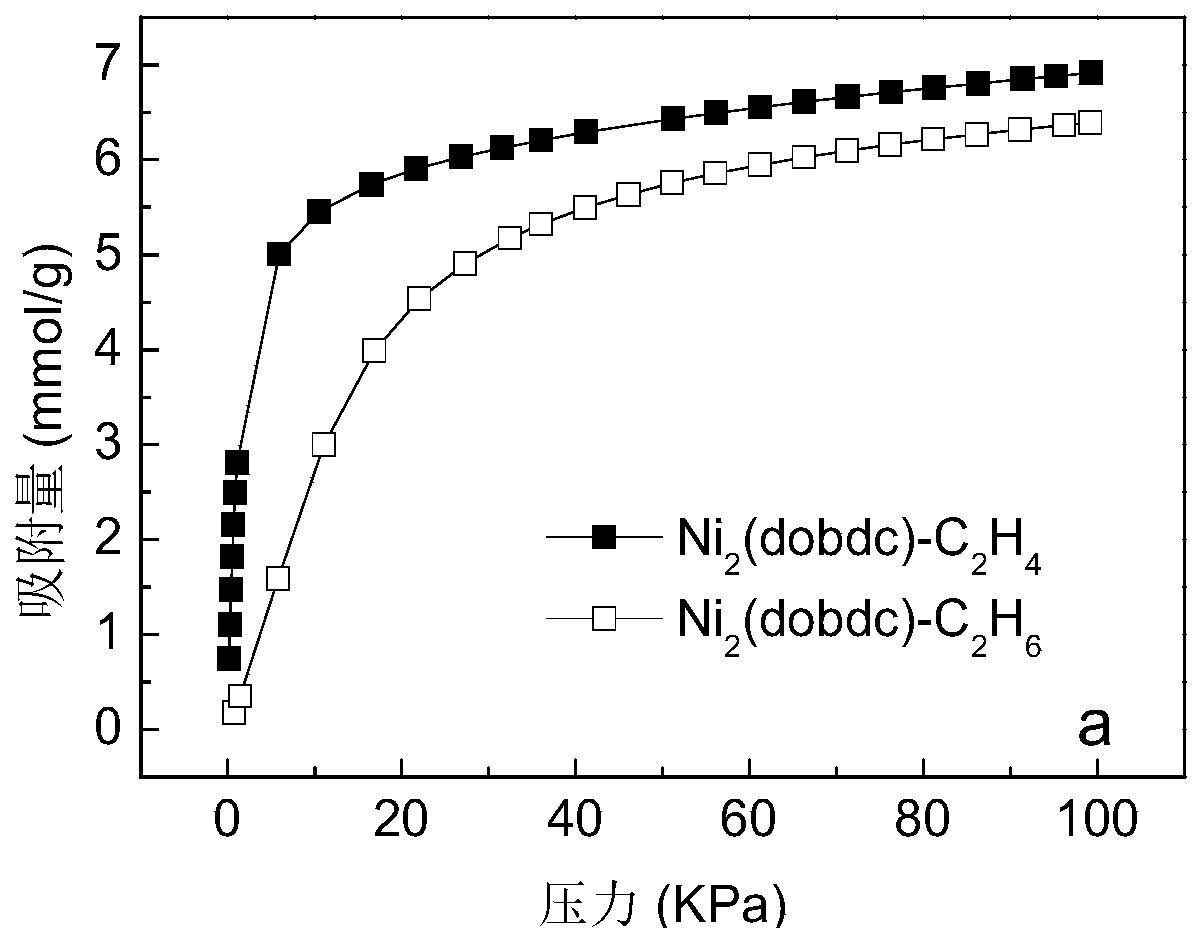

A technology of gly-ni-dobdc and adsorbent, which is applied in the field of Gly-Ni-dobdc adsorbent and its preparation, can solve the problem of unsatisfactory separation effect of mixed gas, and achieve the effect of easy realization, good repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

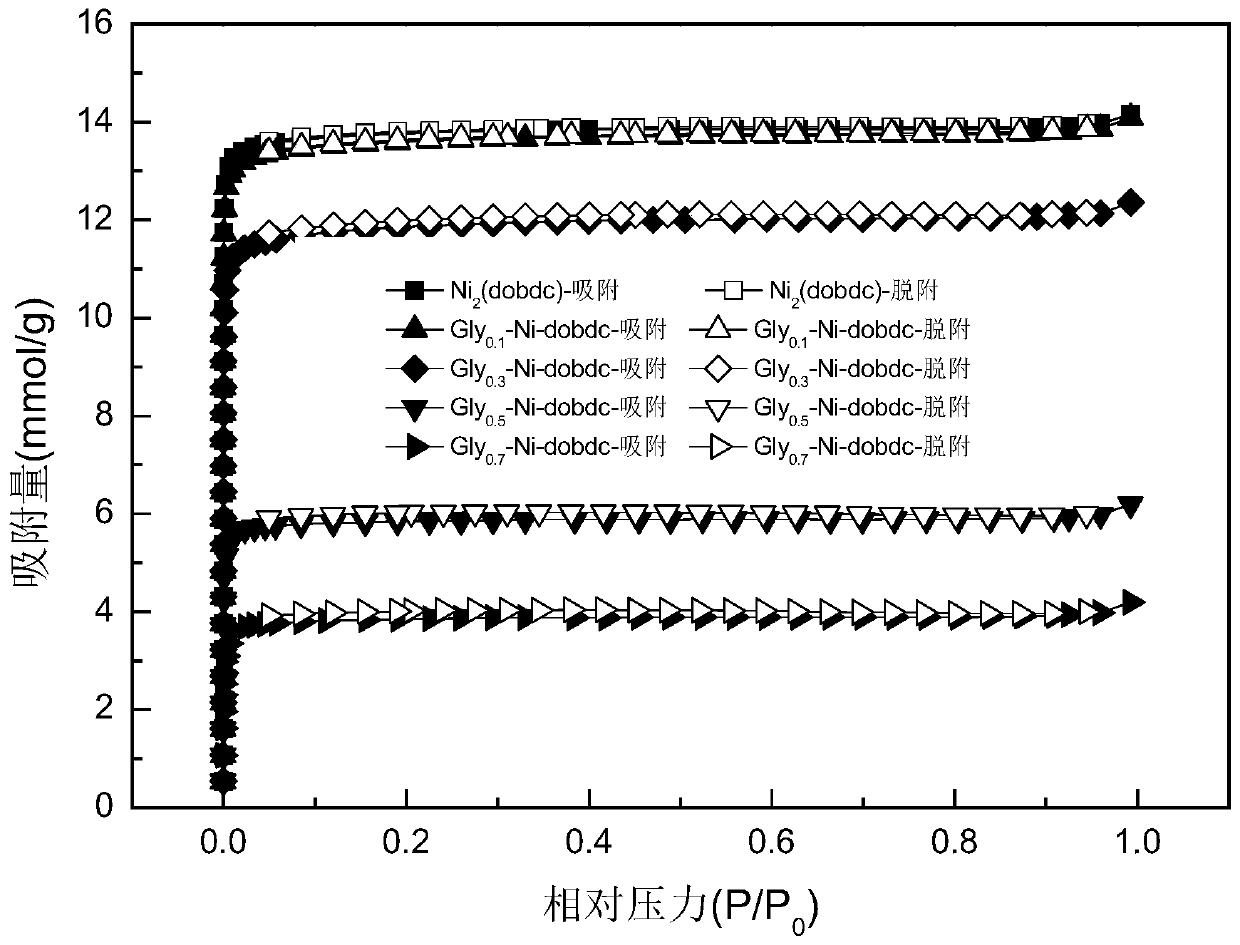

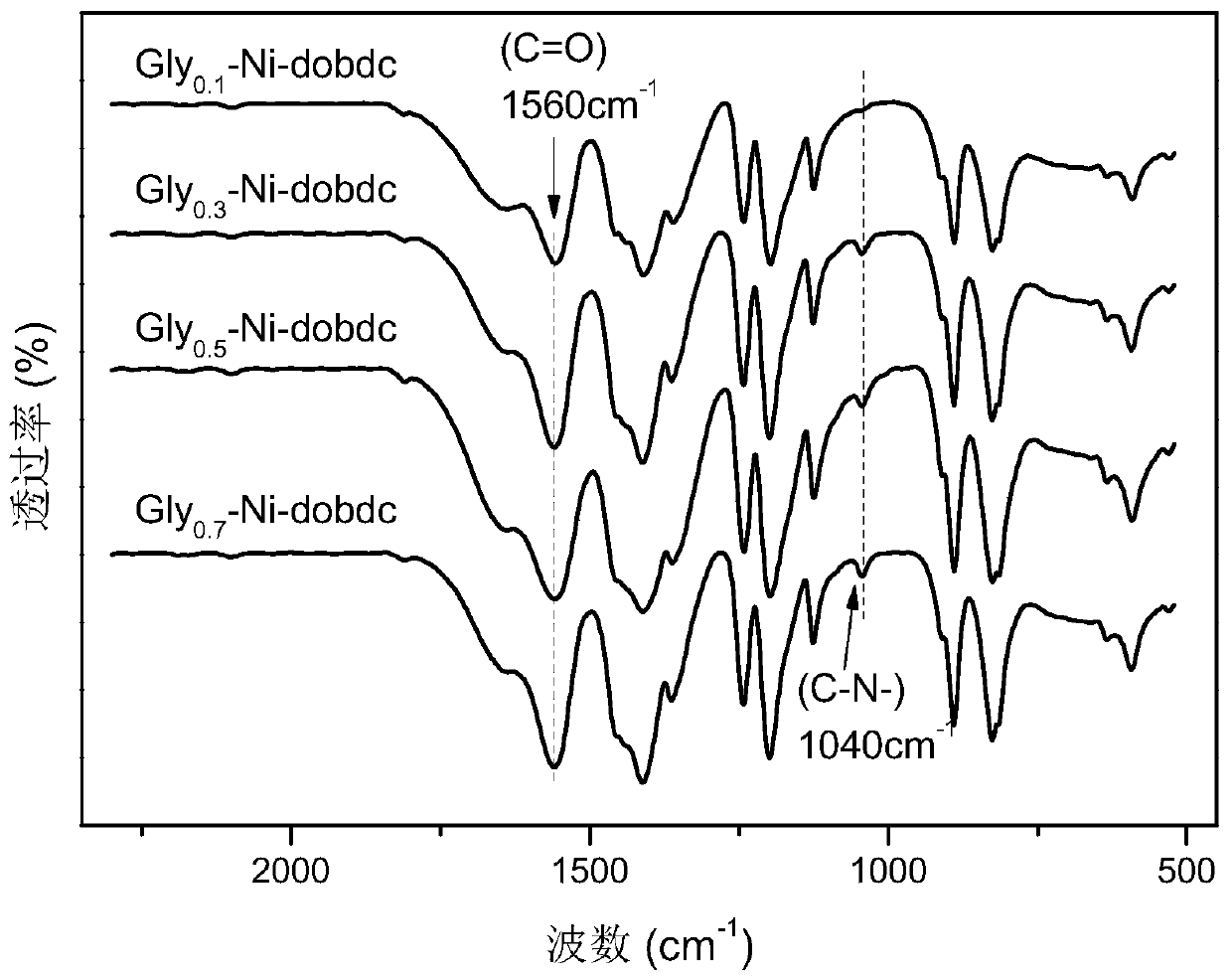

[0035] (1) Gly (0.52mmol, n 1 ) and Ni(CH 3 COO) 2 4H 2 O(5.2mmol, n 2 ) dissolved in deionized water (30ml, n 3 ), fully stirred to obtain Gly and Ni 2+ Mixed solution; 2,5-dihydroxyterephthalic acid (dobdc, 2.63mmol, n 4 ) dissolved in tetrahydrofuran (35ml, n 5 ), fully stirred to obtain dobdc solution. The proportion of the amount of each substance is n 1 :n 2 :n 4 = 0.1:1:0.5; n 3 :n 5 =1:1.2

[0036] (2) Add the dobdc solution obtained in step (1) to Gly and Ni 2+ In the mixed solution, stir and mix evenly to obtain a reaction solution, transfer it to a reaction kettle, put it in a constant temperature drying oven at 100°C, and react for 65 hours to obtain a reaction product, filter the solution with an organic filter membrane, and soak the solid product in ethanol , filtered and dried to give a brown solid powder.

[0037] (3) Vacuum activate the solid powder obtained in step (2) at 200°C for 12 hours to obtain the Gly-Ni-dobdc adsorbent material, denoted...

Embodiment 2

[0039] (1) Gly (1.56mmol, n 1 ) and Ni(CH 3 COO) 2 4H 2 O(5.2mmol, n 2 ) dissolved in deionized water (35ml, n 3 ), fully stirred to obtain Gly and Ni 2+ Mixed solution; 2,5-dihydroxyterephthalic acid (dobdc, 2.34mmol, n 4 ) dissolved in tetrahydrofuran (35ml, n 5 ), fully stirred to obtain dobdc solution. The proportion of the amount of each substance is n 1 :n 2 :n 4 =0.3:1:0.45; n 3 :n 5 =1:1

[0040] (2) Add the dobdc solution obtained in step (1) to Gly and Ni 2+ In the mixed solution, stir and mix evenly to obtain a reaction solution, transfer it to a reaction kettle, put it in a constant temperature drying oven at 110°C, and react for 75 hours to obtain a reaction product, filter the solution with an organic filter membrane, and soak the solid product in ethanol , filtered and dried to give a brown solid powder.

[0041] (3) Vacuum activate the solid powder obtained in step (2) at 250°C for 8h to obtain Gly-Ni-dobdc adsorbent material, denoted as Gly 0.3...

Embodiment 3

[0043] (1) Gly (2.6mmol, n 1 ) and Ni(CH 3 COO) 2 4H 2 O(5.2mmol, n 2 ) dissolved in deionized water (40ml, n 3 ), fully stirred to obtain Gly and Ni 2+ Mixed solution; 2,5-dihydroxyterephthalic acid (dobdc, 3.64mmol, n 4 ) dissolved in tetrahydrofuran (35ml, n 5 ), fully stirred to obtain dobdc solution. The proportion of the amount of each substance is n 1 :n 2 =0.5:1:0.7; n 3 :n 5 =1:0.9

[0044] (2) Add the dobdc solution obtained in step (1) to Gly and Ni 2+ In the mixed solution, stir and mix evenly to obtain a reaction solution, transfer it to a reaction kettle, put it in a constant temperature drying oven at 115°C, and react for 70 hours to obtain a reaction product, filter the solution with an organic filter membrane, and soak the solid product in ethanol , filtered and dried to give a brown solid powder.

[0045] (3) Vacuum activate the solid powder obtained in step (2) at 220°C for 10 hours to obtain the Gly-Ni-dobdc adsorbent material, denoted as Gly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com