Molybdenum disulfide activated carbon fiber composite adsorbent for deeply purifying lead-containing wastewater and preparation method of molybdenum disulfide activated carbon fiber composite adsorbent

A technology of activated carbon fiber and molybdenum disulfide, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve problems that are difficult to recycle, cannot be applied to fixed bed water treatment devices, and nano-scale molybdenum disulfide is easy to agglomerate and other problems to achieve the effect of preventing loss, ensuring practical application value, and excellent adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of molybdenum disulfide activated carbon fiber composite adsorbent in the present embodiment is as follows:

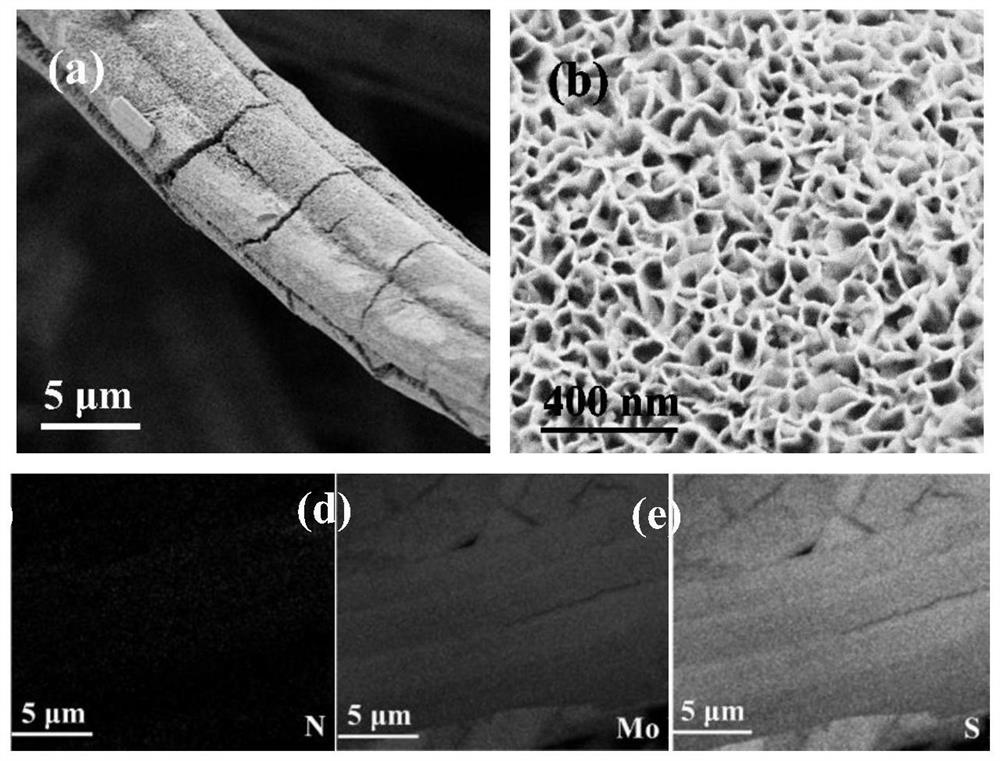

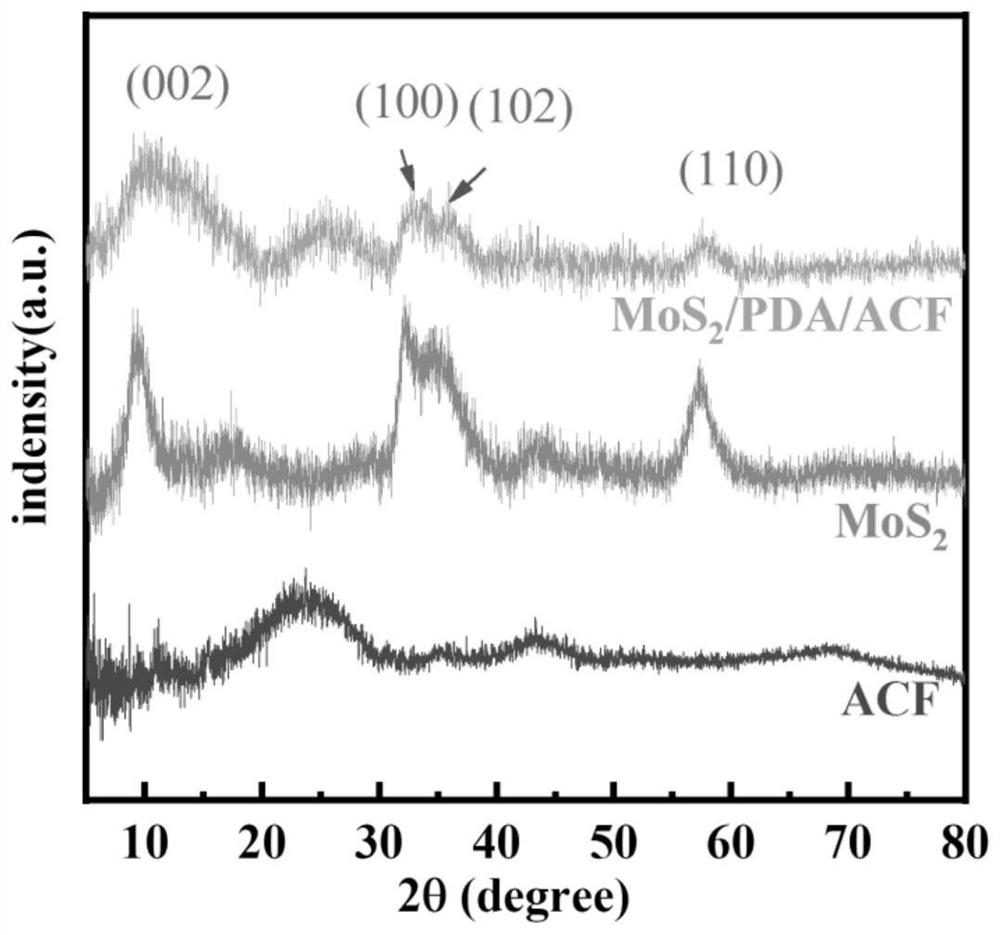

[0030] (1) Utilize the plant pulverizer to pulverize the activated carbon fiber felt into uniform short fibers, wash and dry with deionized water. (2) Add the treated activated carbon fiber into the dopamine hydrochloride solution with a concentration of 2g / L at pH8.4-8.5, wherein the mass ratio of activated carbon fiber to dopamine hydrochloride is 1:1, and the dopamine hydrochloride solution is buffered with 10mM Tris-HCl Solution preparation; then the mixture was placed in a shaker, shaken at 25°C for 24h, the obtained product was washed alternately with deionized water and ethanol three times, and then dried in a drying oven at 60°C for 12h. (3) Add the compound obtained in step (2) into (NH 4 ) 6 Mo 7 o 24 4H 2 O and CN 2 h 4 In the mixed solution of S, wherein activated carbon fiber, (NH 4 )6 Mo 7 o 24 4H 2 O and CN 2 h ...

Embodiment 2

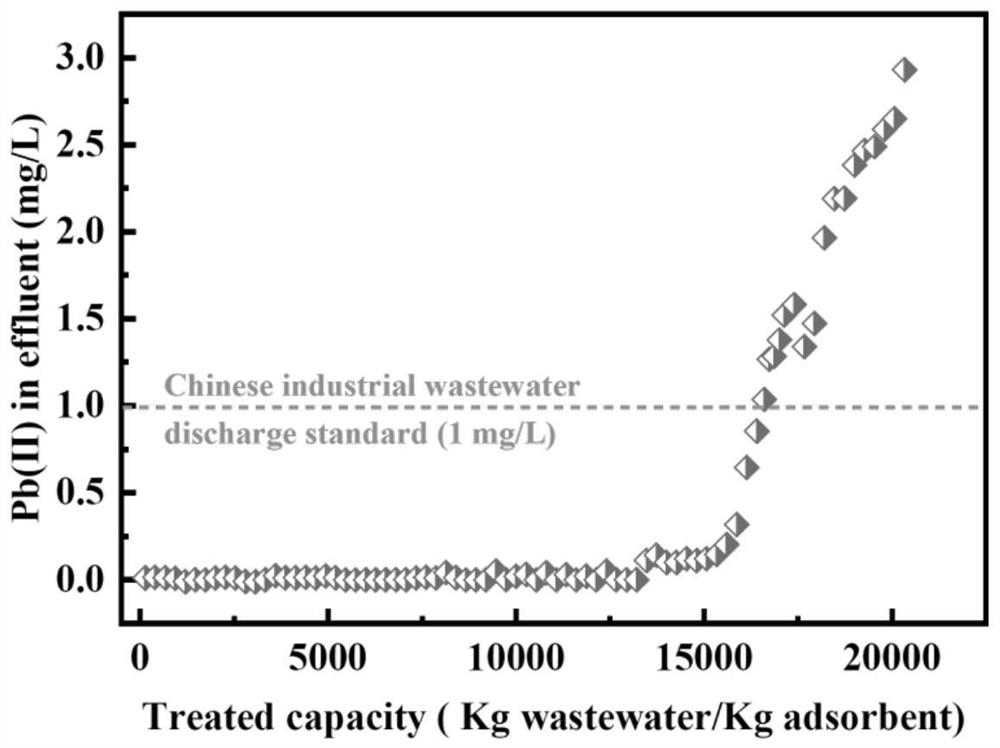

[0033] Prepare Pb with a certain concentration range from 20mg / L to 500mg / L 2+ solution, respectively add 25mg composite material to 50mL Pb with different concentrations above 2+ In the solution, at a temperature of 25°C, vibrate in a shaker at a speed of 160r / min for 24 hours to balance, then take its supernatant, measure its concentration at equilibrium with an inductively coupled plasma emission spectrometer (ICP), and calculate Under these conditions, molybdenum disulfide activated carbon fiber composites are effective against Pb 2+ The adsorption capacity can reach 393mg / g.

Embodiment 3

[0035] Prepare 2 different sets of competing ion solutions to ensure Pb 2+ Concentration is 100mg / L, where Ca 2+ , Mg 2+ Concentration and 100mg / L of Pb respectively 2+ The molar ratios are 0, 5, 10, 20, 40, 60, 100, respectively. Add 25mg of composite materials to 50mL of the above different solutions, shake in a shaker at a speed of 160r / min for 24 hours at a temperature of 25°C until equilibrium, then take the supernatant, and measure its equilibrium concentration by ICP. The results showed that in the presence of a large amount of calcium and magnesium ions, the removal efficiency of molybdenum disulfide activated carbon fiber composites for lead remained stable, showing excellent adsorption selectivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com