Flexible rope driving series-parallel spraying robot mechanism and operating method thereof

A spraying robot and cable-driven technology, applied in the field of robotics, can solve problems such as limited working space, small load capacity, and poor dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

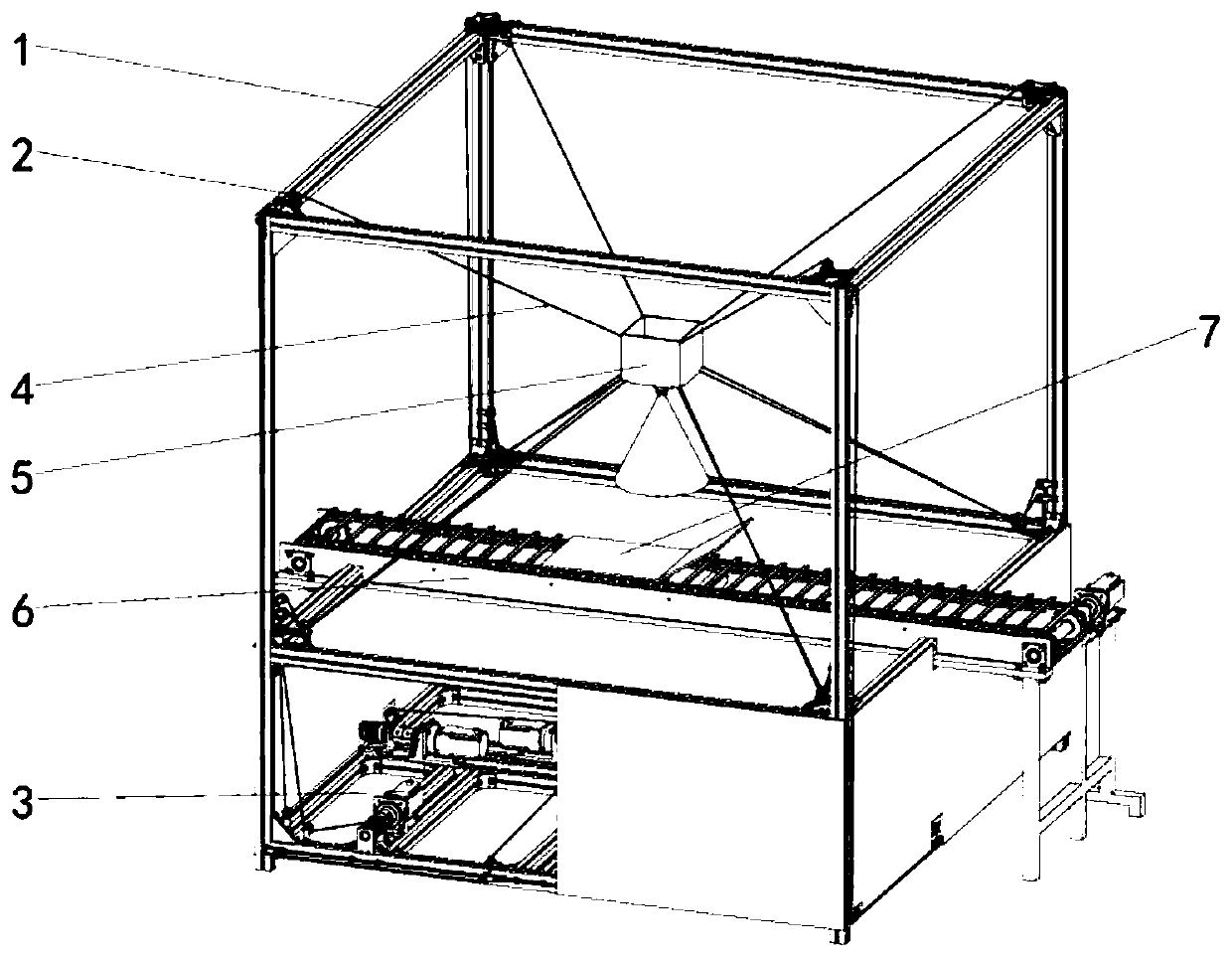

[0065] combine figure 1 , 2 , 3, 10, 11, 12 and 13, a cable-driven hybrid spraying robot mechanism, consisting of a static platform frame 1, a cable guide pulley assembly 2, a driving mechanism 3, a transmission cable 4, a moving platform 5, and workpiece transmission The organization consists of 6.

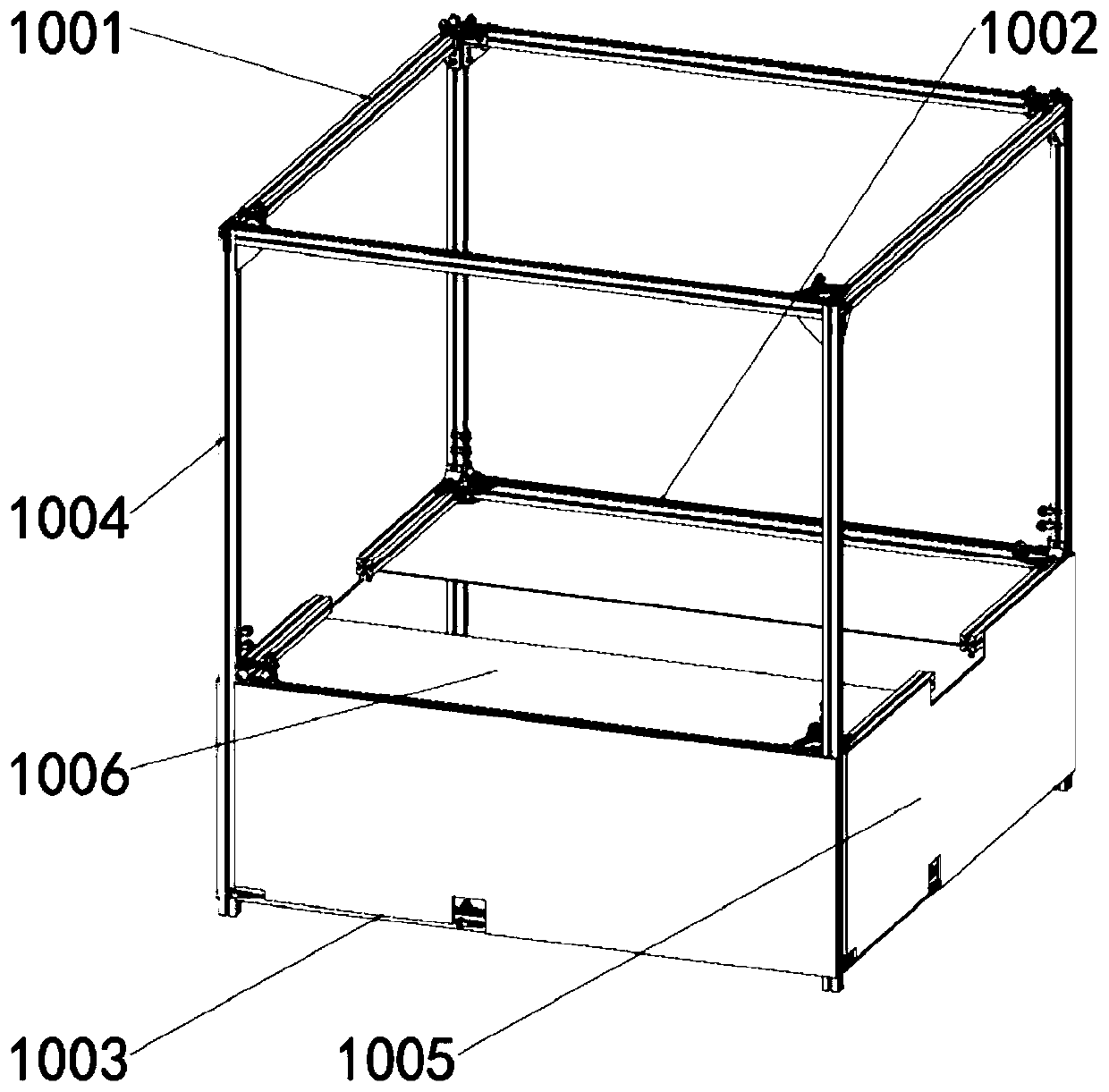

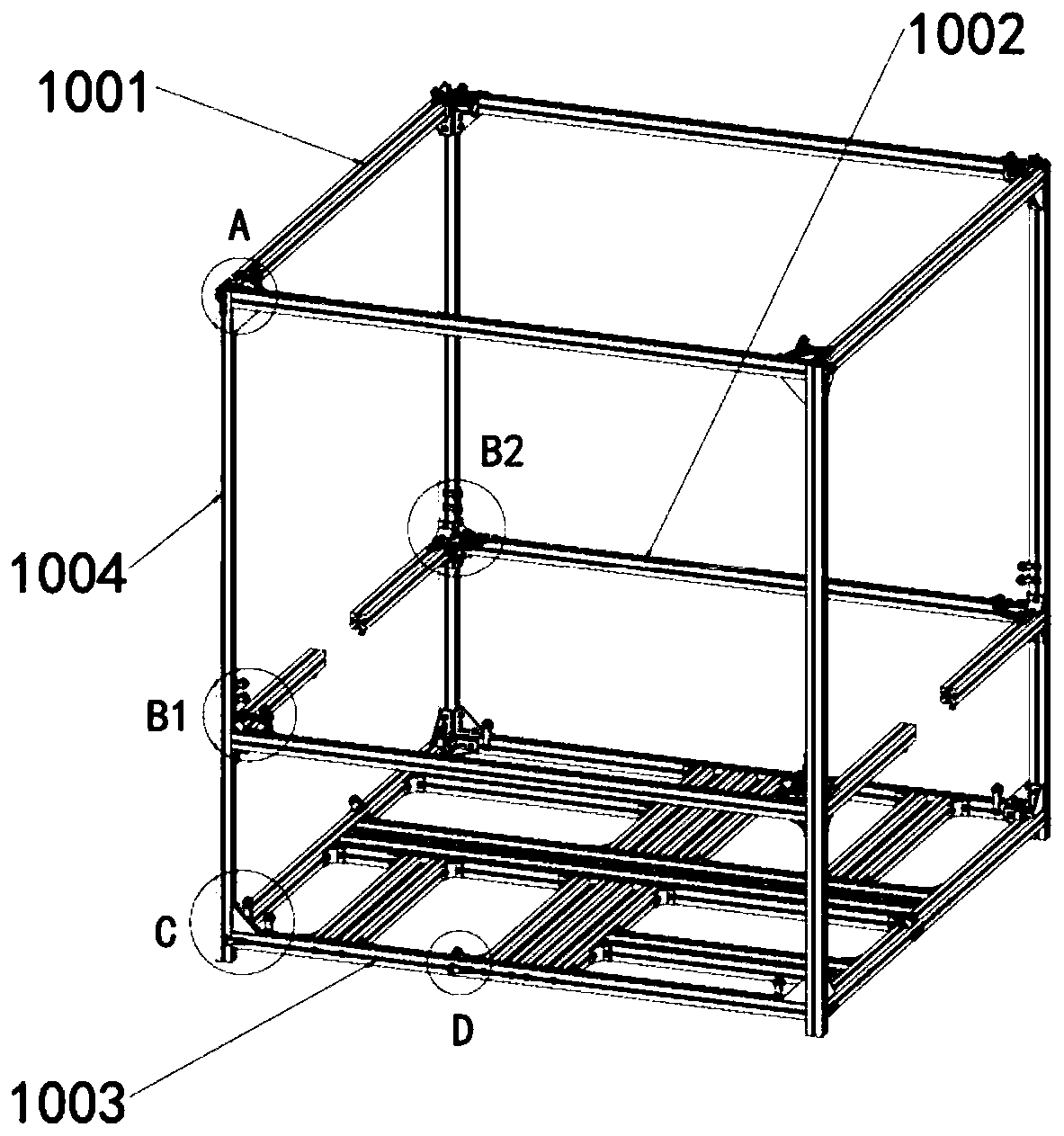

[0066] Wherein, the static platform frame 1 is composed of an upper rectangular frame 1001 , a lower rectangular frame 1002 , a frame base 1003 , a vertical frame edge 1004 , side baffles 1005 and a bottom baffle 1006 . Four vertical frames 1004 connect the upper rectangular frame 1001, the lower rectangular frame 1002 and the frame base 1003 to form two upper and lower three-dimensional spaces, wherein the upper three-dimensional space will be the movement space of the moving platform 5, and the lower three-dimensional space will centrally place the driving mechanism 3. Install side baffles 1005 on the four sides of the lower three-dimensional space, and install a bottom baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com