Pallet fork carrying AGV

A kind of fork, a pair of technology, applied in the direction of lifting device, lifting equipment safety device, etc., can solve the problem of limited driving passage, danger, dumping of goods, etc., to reduce the width of the running passage, run smoothly, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

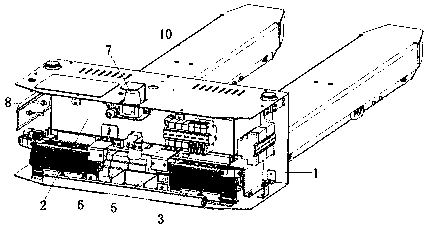

[0031] The AGV mechanism of the present invention adopts two-dimensional code + inertial or laser navigation, cooperates with the dispatching command system to control the flow of the AGV, and realizes fully automatic operation;

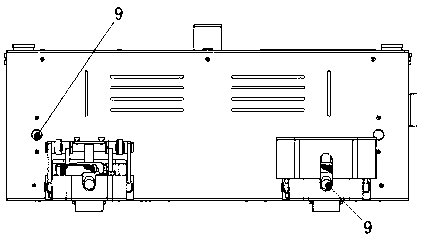

[0032] In the present invention, the front end of the AGV cover 1 is provided with an obstacle avoidance sensor 7 and an edge strip 11. The obstacle avoidance sensor 7 provides a large field of view protection, and the edge strip 11 can conduct the internal circuit through impact deformation when the obstacle avoidance error occurs. Control the AGV parking; the rear end of the AGV cover 1 is equipped with two first position diffuse reflection photoelectric mechanisms 9 with different monitoring orientations, so as to avoid damage and deviation caused by the excessive driving of the AGV and impact on the cargo, and improve safety and accuracy; the end of the AGV fork is set Two-way diffuse reflection photoelectric, to avoid hitting the pallet due to de...

specific Embodiment 2

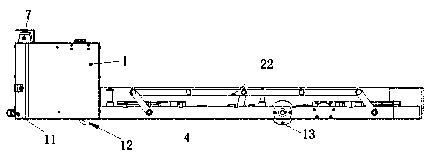

[0036] In the present invention, the horizontal support rod 22 and the two side connecting rods 21 form a parallelogram structure to ensure the horizontal state of the horizontal support rod 22. A number of oblique push connecting shafts 23 are evenly distributed on the horizontal support rod 22. Based on the horizontal support rod 22 The unique sliding jacking principle of the parallelogram structure, the obliquely pushing the connecting shaft 23 can reduce friction during the process of lifting the upper fork 10 by the horizontal support rod 22, the lifting process is smoother, no dry grinding, and the service life is improved; the upper fork 10 The horizontal displacement is limited by two limiting components 24 [shaft sleeve + shaft] to ensure that it can only be lifted vertically;

[0037] The upper fork 10 is placed flat on two horizontal support rods 22, fully supported by several bearing points, and the movement / support stability of the upper fork 10 is increased;

[0...

specific Embodiment 3

[0042] In the AGV of the present invention, a pair of vertical plates 39 are vertically welded on the pallet 4 at the bottom of the fork, the universal wheels 12 and the drive wheels 13 are installed on the vertical plates 39 through fasteners, and the load-bearing all acts on the vertical plates 39; The plates are all welded with the vertical plate 39, and the vertical plate 39 acts as a skeleton;

[0043] The drive structure in the AGV of the present invention includes a drive shaft 37, a drive wheel 13, a bearing seat 33, a long shaft sleeve 36, a short shaft sleeve 32, a tensioning device, a motor power group 18 and a sprocket chain;

[0044] Wherein, the long and short shaft sleeves are all sleeved on the drive shaft 37 and pass through the drive installation hole 38, and the two ends of the long and short shaft sleeves are all in contact with the bearing seat 33 and the driving wheel 13 / driven sprocket 34 to play a position-limiting role; There is no contact with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com