Phosphogypsum treatment device and method based on sodium sulfate electrolysis

A processing device, sodium sulfate technology, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of high energy consumption, reduced membrane performance, high operating voltage, and achieve the effects of low investment, convenient movement, and large electrode reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

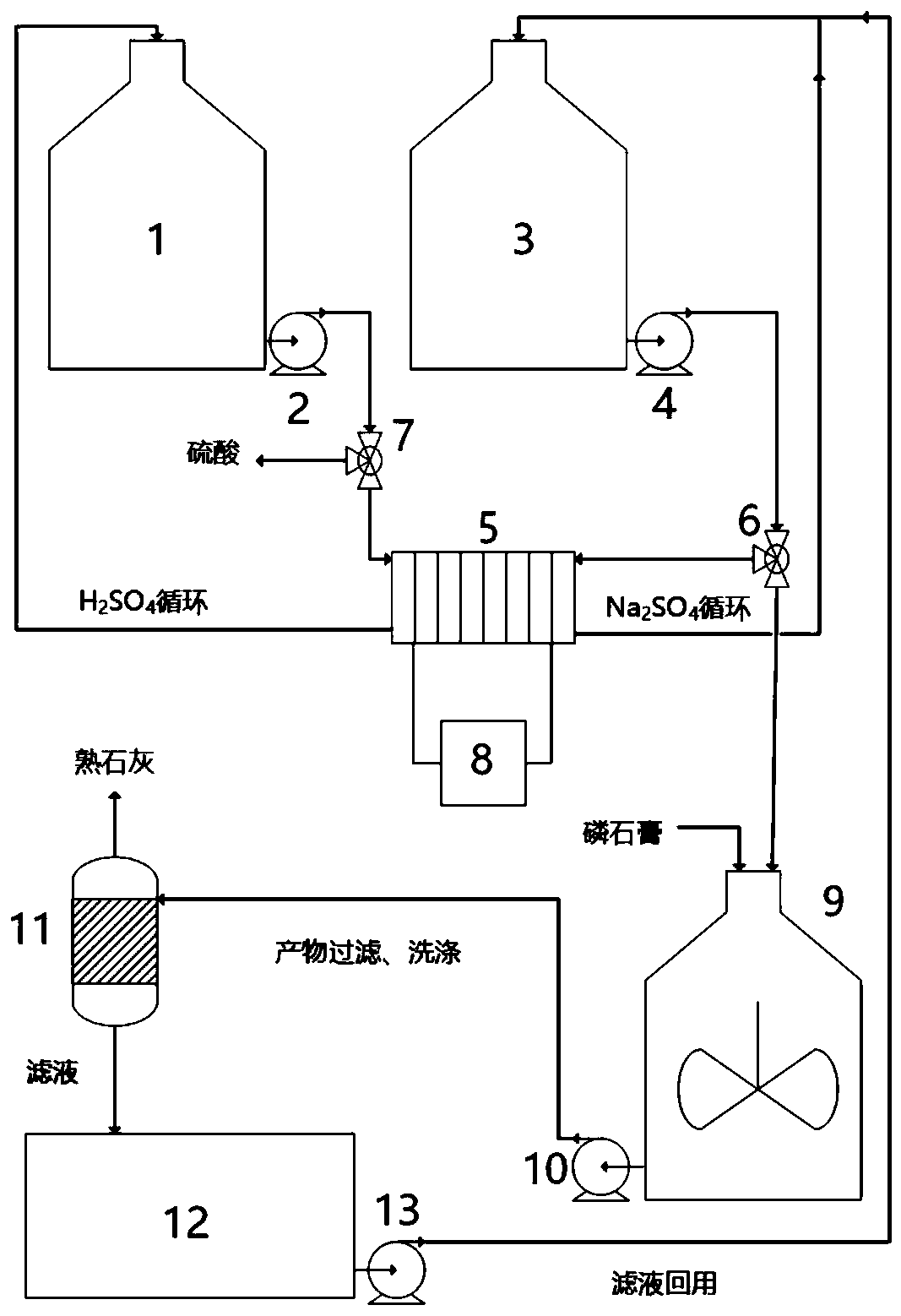

[0051] In this embodiment, the phosphogypsum treatment device based on sodium sulfate electrolysis is specifically: a sulfuric acid storage tank 1, an acid circulation pump 2, a sodium sulfate storage tank 3, an alkali circulation pump 4, a sodium sulfate electrolyzer 5, and a three-way valve 6. The electrolysis unit composed of alkali three-way valve 7 and DC power supply 8 and the reaction unit composed of phosphogypsum reactor 9, slag discharge pump 10, filter 11, filtrate storage tank 12, and return pump 13, and several valves / flow meter composition. The sulfuric acid solution in the sulfuric acid storage tank 1 is pumped into the anolyte flow channel 19 of the electrolyzer through the pipeline by the acid circulation pump 2, and the sulfuric acid solution flows back to the sulfuric acid storage tank 1 through the pipeline after flowing through the anode chamber 15 of the electrolyzer. The sodium sulfate solution in the sodium sulfate storage tank 3 is pumped into the ca...

Embodiment 2

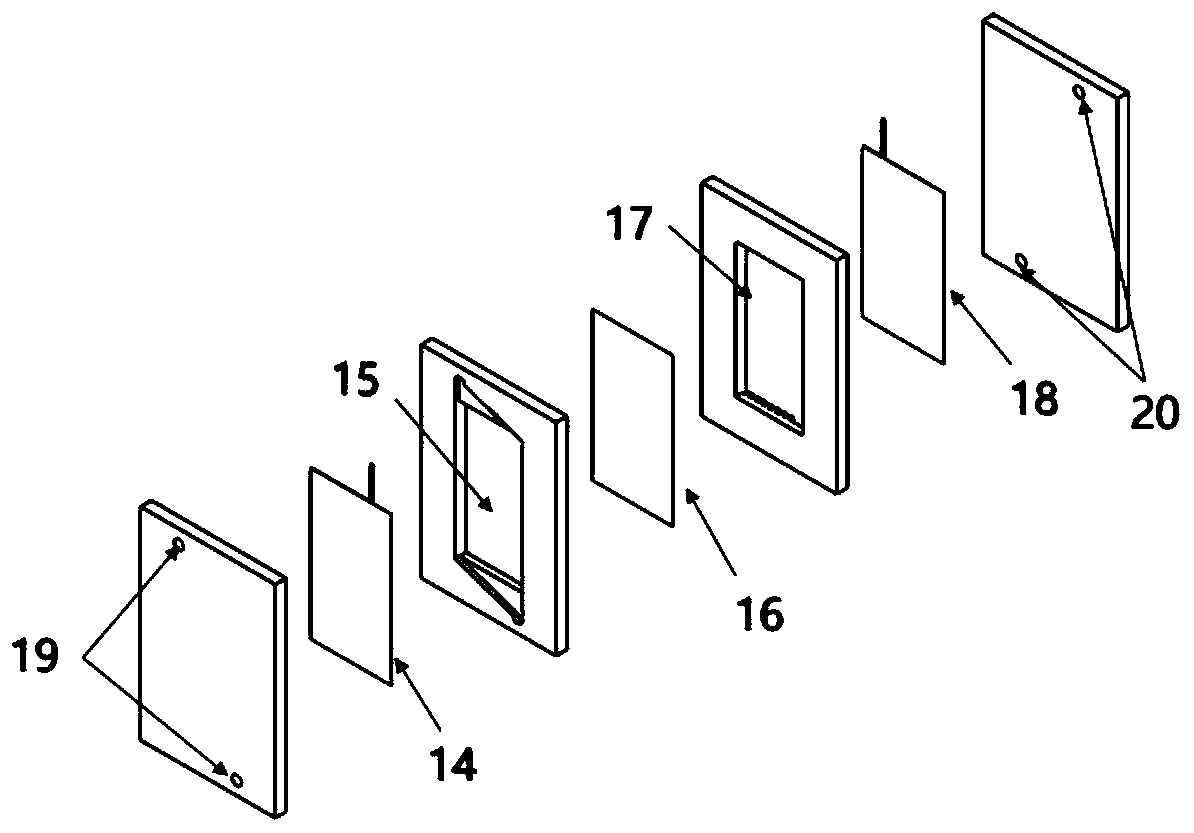

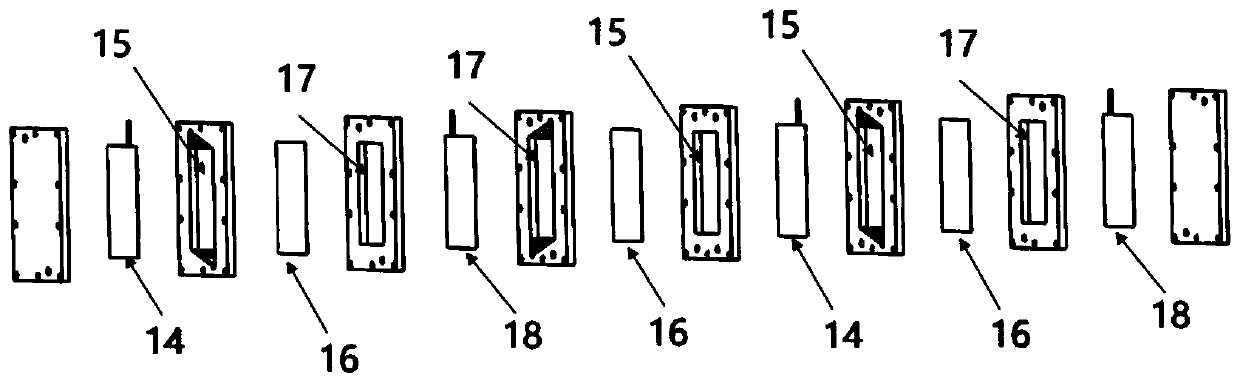

[0055] figure 2 It is an exploded schematic diagram of a dual-channel sodium sulfate electrolyzer provided by a preferred embodiment of the present invention. The basic composition of sodium sulfate includes anode 14, anode chamber 15, anion exchange membrane 16, cathode chamber 17, cathode 18, anolyte channel 19 and catholyte channel 20. This structure is the basic structural unit of the multi-channel electrolyzer of the present invention, and multiple channels are stacked with this double-channel structure.

[0056] The concrete parts of described sodium sulfate electrolyzer are anode 14, anode chamber 15, anion exchange membrane 16, cathode chamber 17, cathode 18. The basic structure is a single membrane with two chambers, which are stacked as a basic unit to form a multi-channel electrolyzer, and the anode chamber 15 and the cathode chamber 17 are connected in parallel. The anode / cathode electrolyte flows into the individual anode / cathode chambers respectively through t...

Embodiment 3

[0060] Figure 5 It is a schematic diagram of a columnar flow field on the anode side provided by a preferred embodiment of the present invention. The anolyte flows into the anode chamber 15 through the anolyte channel 19 through the columnar flow field, and finally returns to the anolyte channel 19 through the columnar flow field, and the anolyte is more evenly distributed after passing through the columnar flow field. The catholyte channel 20 flows directly through this region, with no corresponding outlet.

[0061] Figure 6 It is a schematic diagram of an anode serpentine flow field provided by a preferred embodiment of the present invention. The anolyte flows into the serpentine anode compartment 15 through the anolyte channel 19 and finally returns to the anolyte channel 19 . The catholyte channel 20 flows directly through this region, with no corresponding outlet.

[0062] Figure 7 It is a schematic diagram of a river-shaped flow field on the cathode side provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com