Improved structure of metallized safety film explosion-proof capacitor

A capacitor structure and safety film technology, which is applied in the field of capacitors to achieve good electrical conductivity and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

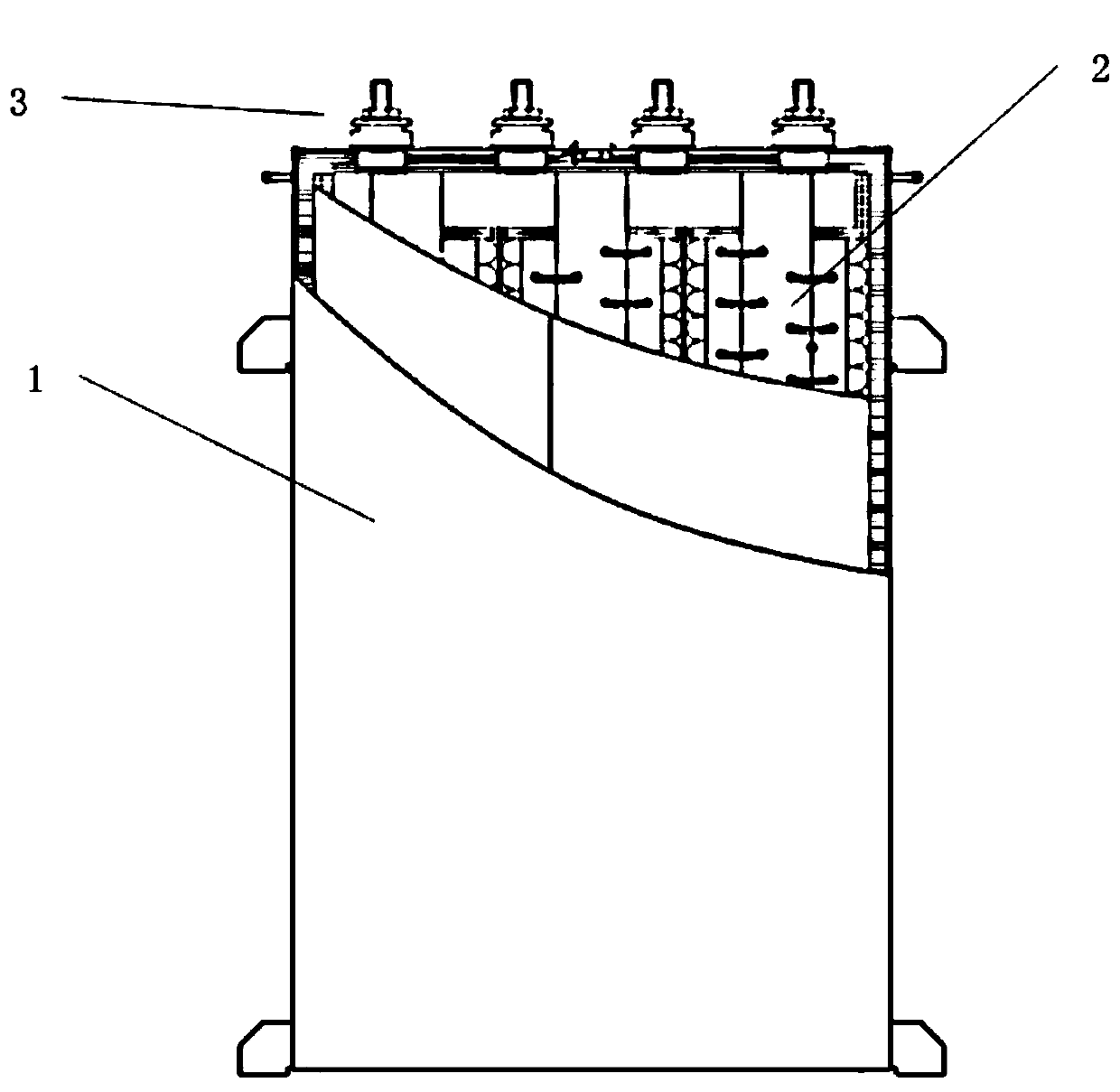

[0037] please see figure 1 and Figure 6 , the present invention relates to a structural improvement of a metallized safety film explosion-proof capacitor, which is characterized in that it includes:

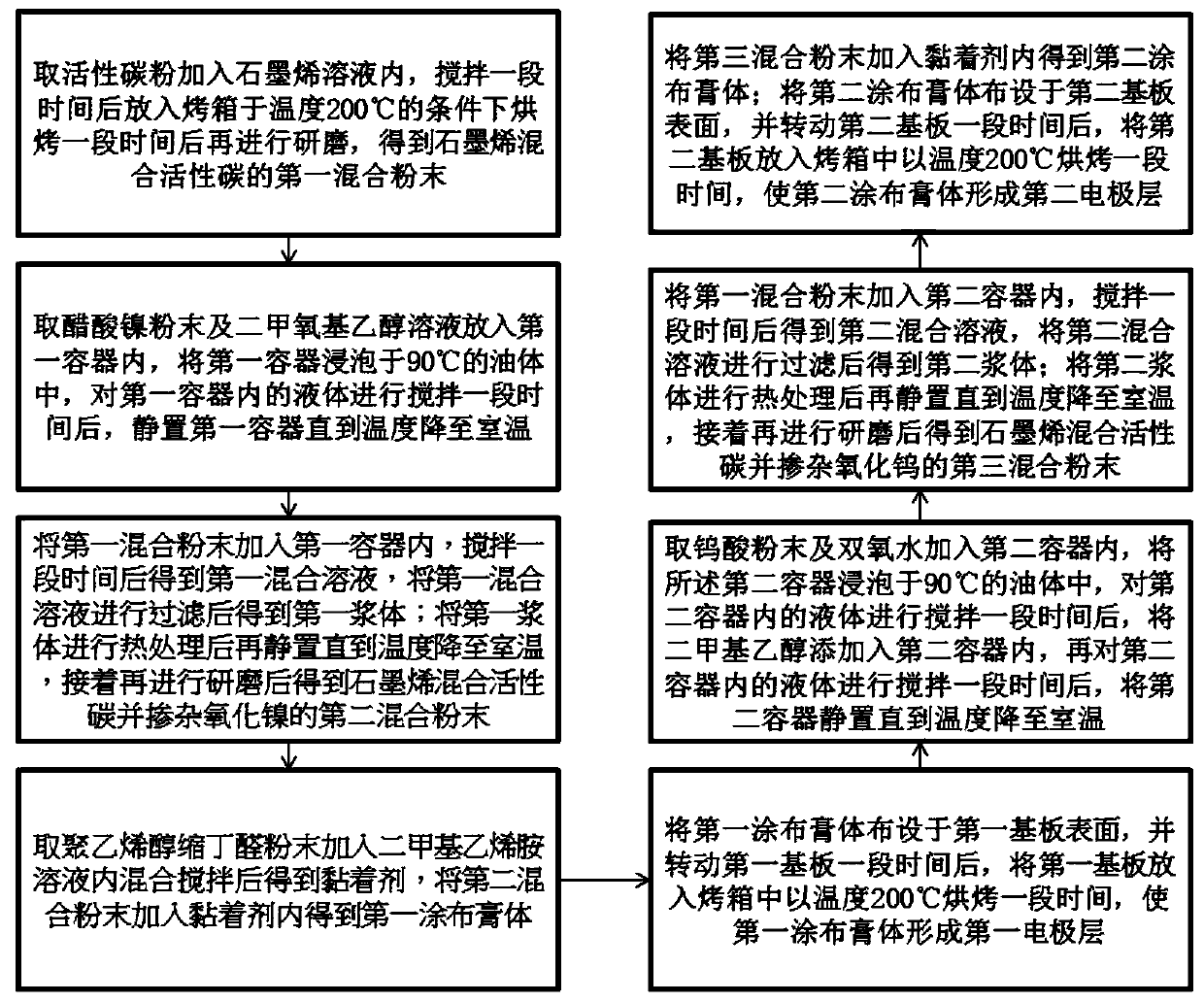

[0038] Housing 1, metallized safety film explosion-proof capacitor body 2, the metallized safety film explosion-proof capacitor body 2 is arranged in the housing 1, and the metallized safety film explosion-proof capacitor body 2 includes a first plate 21 and the second pole plate 22, the first pole plate 21 is preferably used as an anode, and the second pole plate 22 is preferably used as a cathode, and the first pole plate 21 includes a first substrate 211 and is located on the The first electrode layer 212 on the surface of the first substrate 211, the first electrode layer 212 is made of graphene mixed with activated carbon and doped with nickel oxide; the second plate 22 includes a second substrate 221 and is located on The second electrode layer 222 on the surface of the ...

Embodiment 2

[0052] please see Figure 4 , the electrolyte of the metallized safety film explosion-proof capacitor body 2 is preferably a colloidal polymer electrolyte film. The following introduces the manufacturing method of the colloidal polymer electrolyte film:

[0053](1) Take polyethylene glycol (PEG), deionized water and nitrogen into the double-neck reactor and heat and stir for a period of time. The temperature is preferably around 40°C, and then add acrylonitrile (PAN) to the double-neck reaction The reactor is then heated and stirred for a period of time, and the temperature is also preferably around 40°C; the cerium nitrate ammonium is dissolved in the nitric acid solution to obtain the third mixed solution; the third mixed solution is slowly added to the double-necked reactor, and wait until After the complete reaction, a heterogeneous solution is obtained. After the heterogeneous solution is suction-filtered, it is washed repeatedly with deionized water and acetone, and the...

Embodiment 3

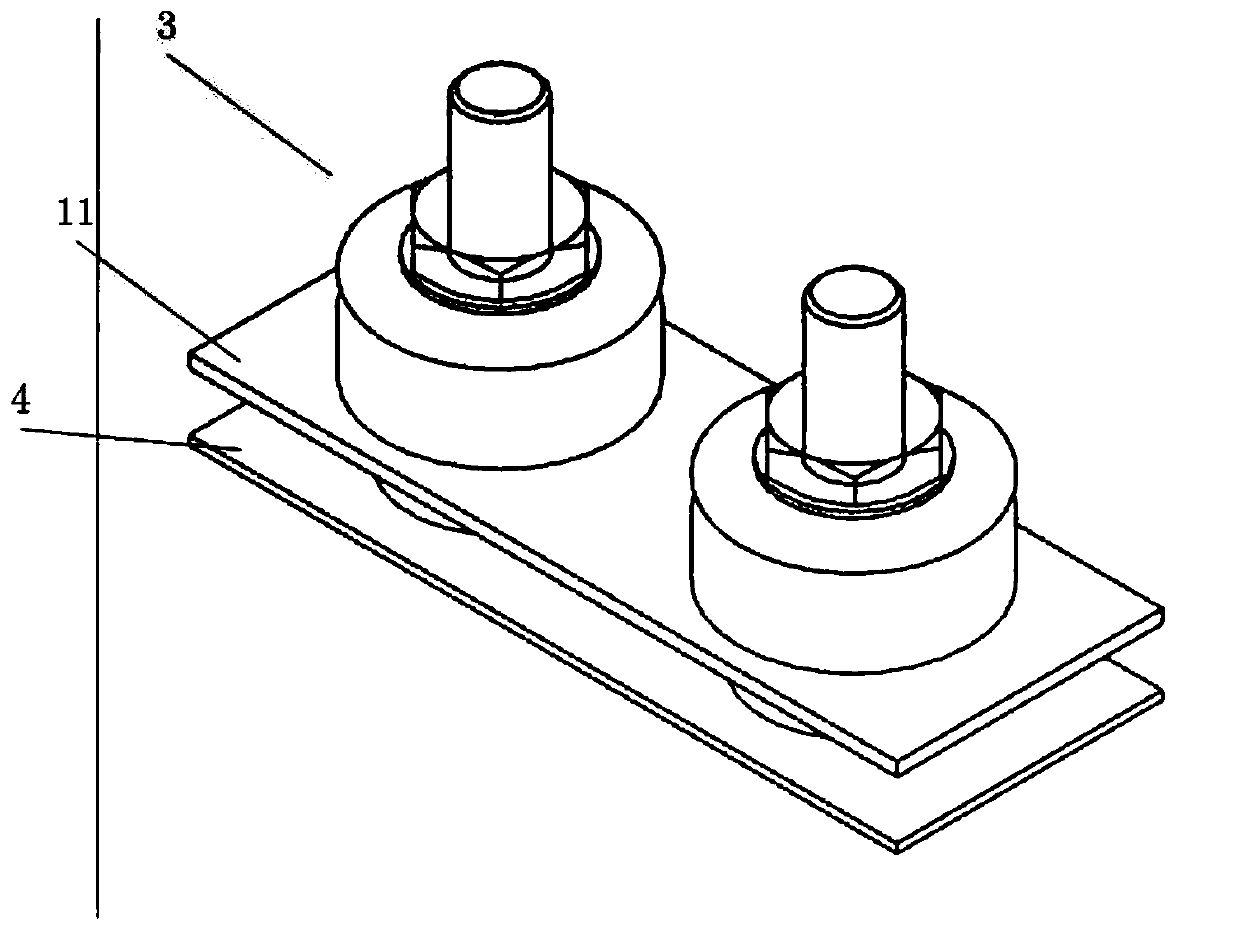

[0058] please see figure 2 , the implementation method is: the surface of the housing 1 is provided with several conductive terminals 3 arranged in sequence at intervals, and each conductive terminal 3 is electrically connected to the metallized safety film explosion-proof capacitor body 2, and each conductive terminal 3 The top wall 11 of the housing 1 and the strip plate body 4 respectively pass through the bottom end of the housing 1 in sequence, and there is a distance between the strip plate body 4 and the top wall 11 of the housing 1 .

[0059] In this way, through the spaced apart top wall 11 and strip-shaped plate body 4 , the conductive terminals 3 can be more stably arranged on the top surface of the housing 1 , and are not easily damaged by external force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com