Quantum dot LED packaging structure and manufacturing method thereof

A technology of LED packaging and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of inability to export heat from LED light sources in time, low color saturation, and insufficiently bright colors, so as to improve service life and high luminous efficiency. , the effect of good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

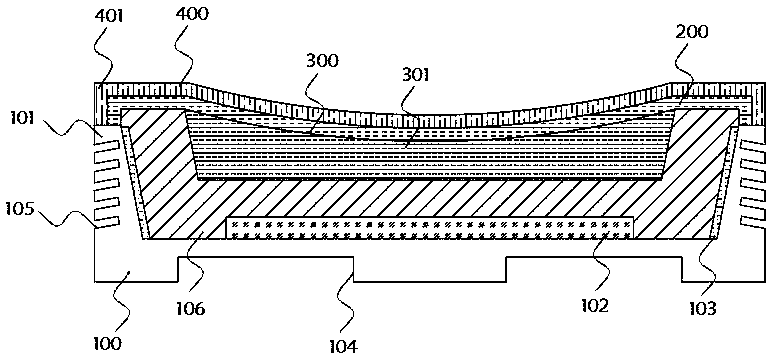

[0030] see Figure 1-Figure 3 As shown, one of the purposes of this embodiment is to provide a quantum dot LED packaging structure, including a substrate 100, the two ends of the substrate 100 are integrally formed with side baffles 101, the interior of the substrate 100 is provided with an LED chip 102, and the substrate 100 The top is provided with an inner barrier layer 200, the side of the inner barrier layer 200 close to the LED chip 102 is recessed inwardly with a groove 300, the inside of the groove 300 is provided with a quantum dot layer 301, and the gap between the quantum dot layer 301 and the LED chip 102 is covered with Silicone layer 106.

[0031] In this embodiment, the inner barrier layer 200 includes one or more of silicon dioxide, aluminum nitride, aluminum nitride silicon nitride compound, aluminum oxide, aluminum, silver, lead, and tin, all of which are low Water and oxygen permeability material.

[0032] Further, the side baffles 101 have a right-angled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com