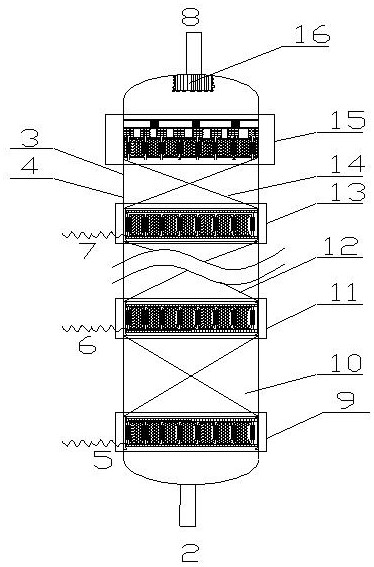

An upflow hydrogenation reactor and its application

A hydrogenation reactor, up-flow technology, applied in chemical instruments and methods, fixed bed hydroprocessing equipment, processing hydrocarbon oil, etc., can solve the problems of uneven distribution of fluid gas, adverse effects on the reaction process, and influence on fluid distribution, etc. Achieve the effect of maintaining long-term stable operation, improving reaction uniformity, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

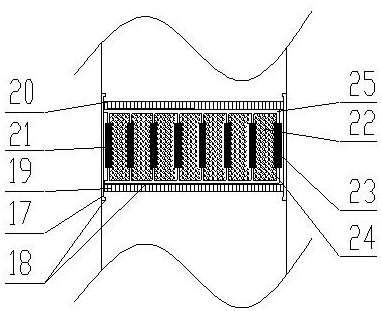

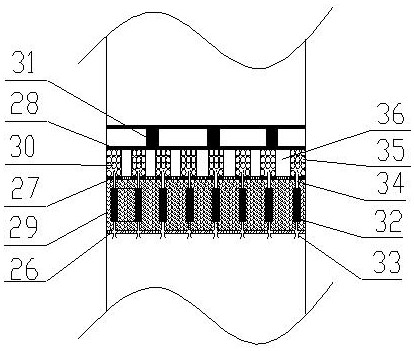

[0050] Using the upflow reactor described in the present invention (two catalyst beds and two floating hydrogen supply filter dust layers are arranged in the reactor), the raw material oil is introduced into the upflow reactor as the reactor feed (the reactor size is 100mm), the hydrogen is divided into two streams and respectively introduced into the first floating hydrogen supply dust filter layer and the first floating hydrogen supply dust filter layer, among which the membrane modules in the first floating hydrogen supply dust filter layer and the second floating hydrogen supply dust filter layer Hydrogen gas is dispersed into microbubbles of 50nm size. The first floating hydrogen supply dust filter layer 180mm, the first catalyst bed 400mm, the second floating hydrogen supply dust filter layer 100mm, the second catalyst bed 600mm, and the ceramic ball layer 100mm are sequentially filled in the reactor along the material flow direction; 1 The floating hydrogen supply dust ...

Embodiment 2

[0052] Using the upflow reactor described in the present invention, the raw material oil is introduced into the upflow reactor (reactor size is 200mm) as the reactor feed, and the hydrogen is divided into three streams and respectively introduced into the first floating hydrogen supply dust filter layer, the second Floating hydrogen supply dust filter layer, the third floating hydrogen supply dust filter layer, wherein the membrane components in the first floating hydrogen supply dust filter layer, the second floating hydrogen supply dust filter layer, and the third floating hydrogen supply dust filter layer disperse hydrogen Microbubbles with a size of 50nm; the reactor is filled with the first floating hydrogen supply dust filter layer 200, the first catalyst bed layer 700 mm, the second floating hydrogen supply dust filter layer 150 mm, and the second catalyst bed along the material flow direction. Layer 800 mm, the third floating hydrogen supply dust filter layer 100 mm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com