High-temperature harmless treatment method for kitchen waste

A technology for the harmless treatment of kitchen waste, which is applied to the removal of solid waste and can solve problems such as human health and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

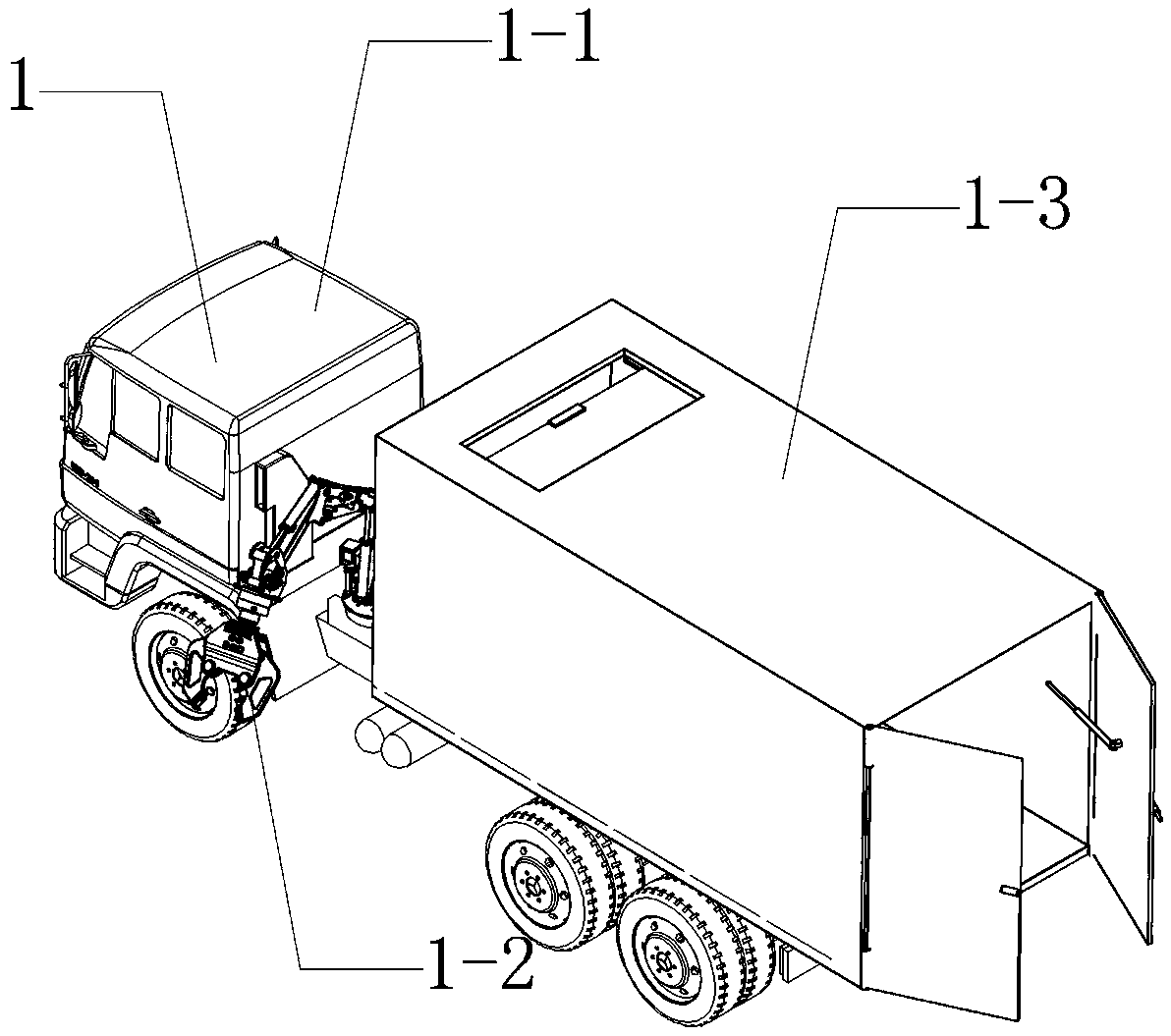

[0057] The high-temperature French method for harmless treatment of kitchen waste includes ① collection of kitchen waste and solid-liquid separation: after the kitchen waste is produced, it is collected in standard collection barrels by hotels, canteens, etc. , and then uniformly collected by the kitchen waste collection truck, the thrown waste is squeezed by a powerful push plate to achieve preliminary solid-liquid separation, the separated liquid enters the liquid storage part at the bottom of the tank, and the solid waste is compressed Stored in the tank, the volume becomes smaller. After repeated filling, it is sent to the food waste recycling plant. All operations on the vehicle are hydraulic automatic control, which can be operated separately in the cab and beside the vehicle;

[0058] ② Solid-liquid separation, sorting and screening of kitchen waste: transport the kitchen waste collected by the kitchen waste collection vehicle to the sorting and screening workshop, open ...

Embodiment 2

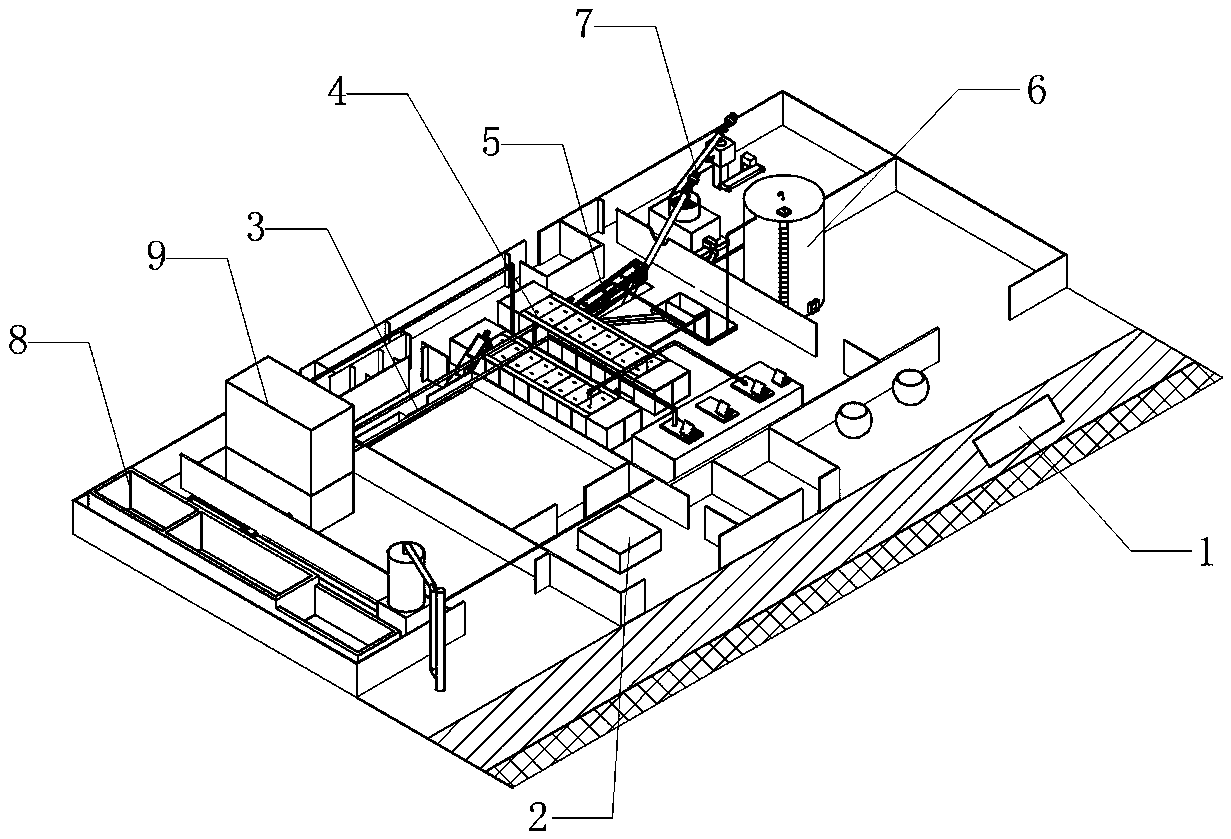

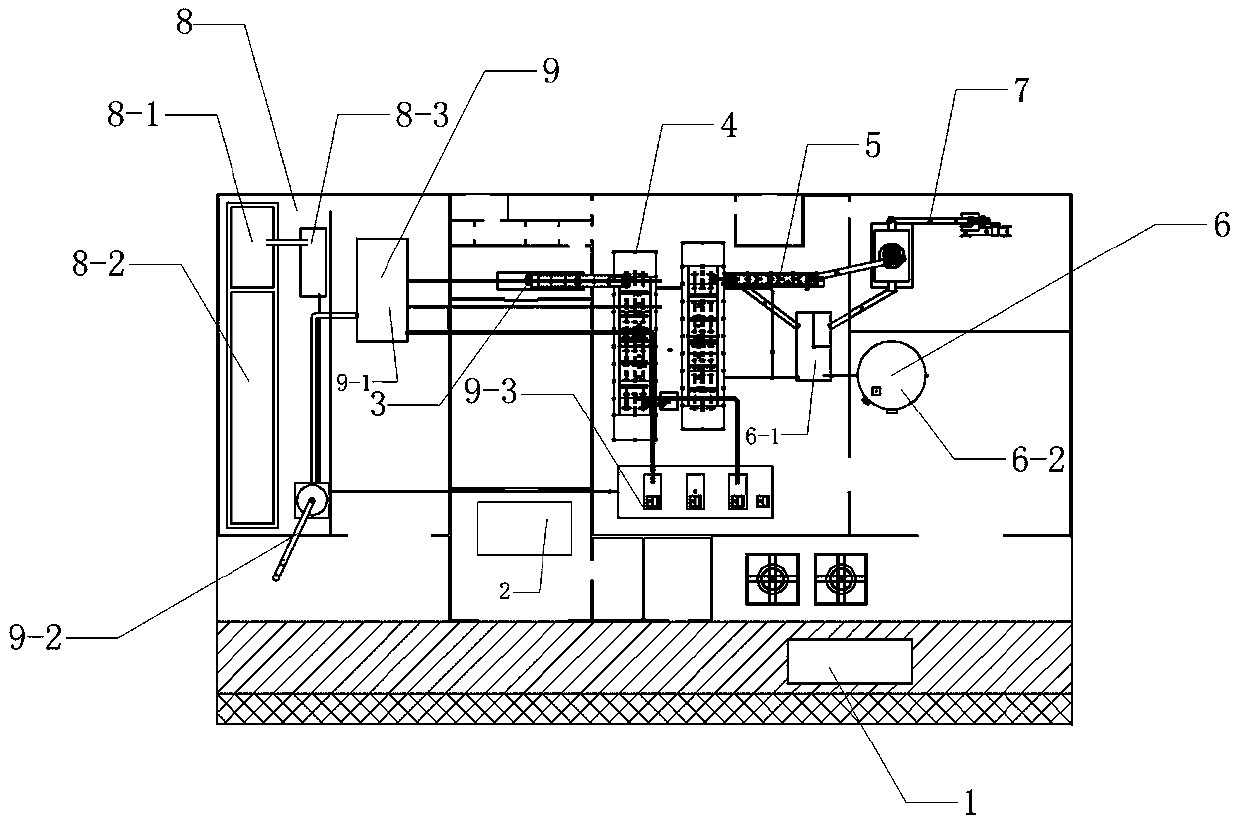

[0077] The harmless treatment method of kitchen waste of the present invention is realized by the following equipment: the equipment includes: kitchen waste collection vehicle 1, kitchen waste vibration screening machine 2, crushing conveyor 3, oil refining device 4, oil residue Separation device 5 , grease collection device 6 , residue press packaging machine 7 , waste water purification and circulation device 8 , waste gas treatment device 9 .

[0078] Kitchen waste collection vehicle 1 is used for unified collection and first solid-liquid separation of kitchen waste;

[0079] The kitchen waste vibrating screening machine 2 is used to screen the non-recyclable solid waste and recyclable solid waste in the kitchen waste through the filter screen according to the volume of the solid waste after the first solid-liquid separation , the liquid waste after the solid-liquid separation is passed through the filter screen for the second solid-liquid separation;

[0080] The crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com