Residual oil hydrodemetallization method

A technology of hydrodemetallization and residual oil hydrogenation, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment, and can solve the problems of complex process, difficult industrialization, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

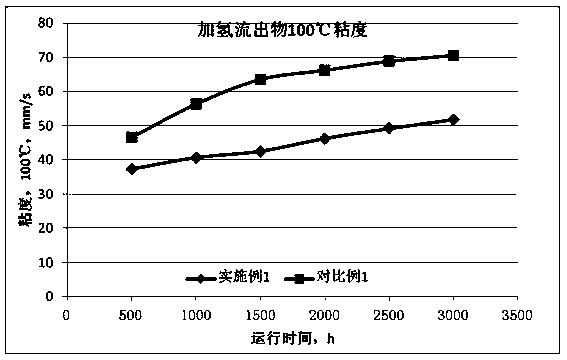

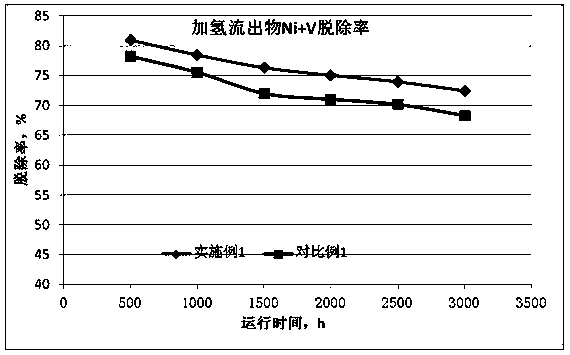

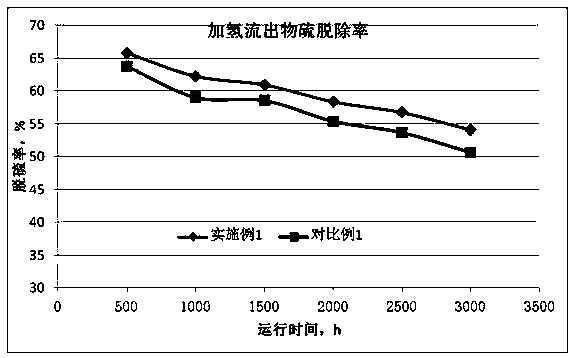

[0055] The method of this example is basically the same as that of Comparative Example 1, except that ethylene tar A is used to replace part of the residue raw material A (see Table 3) and part of the hydrogenation protecting agent is used to replace part of the hydrodemetallization catalyst (see Table 2). . Among them, the process conditions are shown in Table 3, and the fixed-bed hydrogenation results are shown in Table 4. At different operating times, the viscosity of hydrogenation effluent, the removal rate of metal Ni and V, and the removal rate of sulfur are shown in Figure 1-3 .

Embodiment 2

[0057] This example is basically the same as Example 1, except that the feedstock of this example uses residual oil raw material B, ethylene tar B, heavy cycle oil and different catalyst gradation methods. The process conditions are shown in Table 3, and the catalyst gradation is shown in Table 3. Table 2, the fixed bed hydrogenation results are shown in Table 4.

Embodiment 3

[0059]This example is basically the same as Example 1, the difference is that the feedstock of this example uses residual oil raw material A and ethylene tar B and different catalyst gradation methods, the process conditions are shown in Table 3, and the catalyst gradation is shown in Table 2. The bed hydrogenation results are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com