Deformed high-temperature alloy, preparation method of deformed high-temperature alloy, engine hot end rotating part and engine

A technology for deforming high-temperature alloys and rotating parts, which is applied to engine components, machines/engines, mechanical equipment, etc., and can solve problems such as unsatisfactory performance and high cost of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

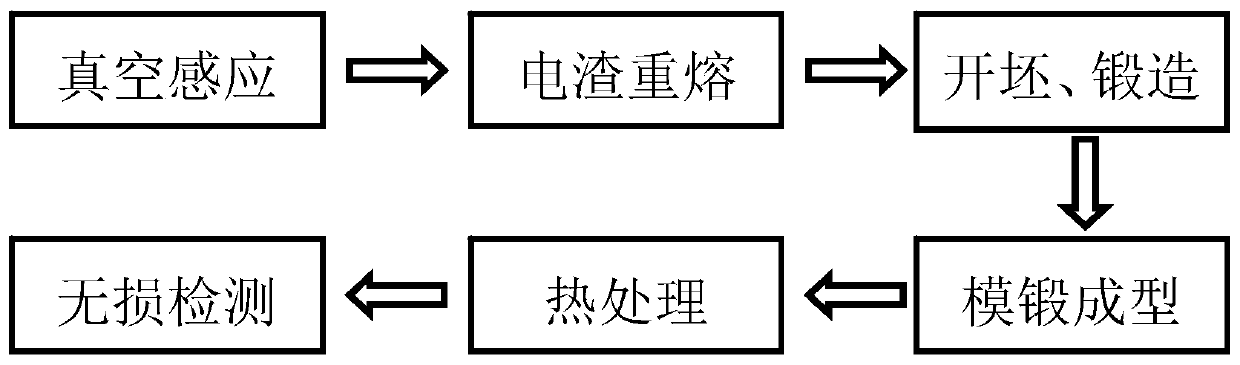

[0057] In another aspect of the present invention, the present invention provides a method for preparing the aforementioned deformed superalloy, comprising the following steps, for details, refer to figure 1 :

[0058] Carrying out vacuum induction smelting, electroslag remelting continuous directional solidification smelting, blank opening, forging, die forging forming and heat treatment on the mixture of each component in sequence to obtain the deformed superalloy;

[0059] Wherein, the heat treatment includes solution heat treatment and aging heat treatment, the temperature of the solution heat treatment is 1100-1180°C (such as 1100°C, 1120°C, 1140°C, 1160°C or 1180°C, etc.), the aging heat treatment The temperature is 760-815°C (for example, it can be 760°C, 780°C, 800°C or 815°C, etc.).

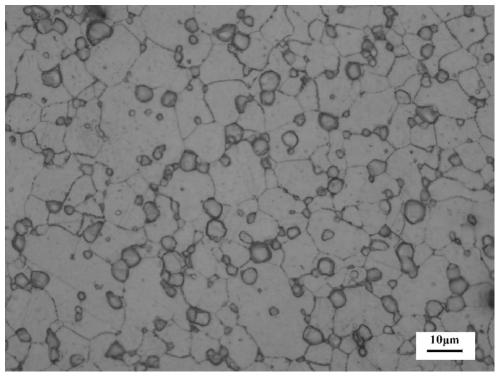

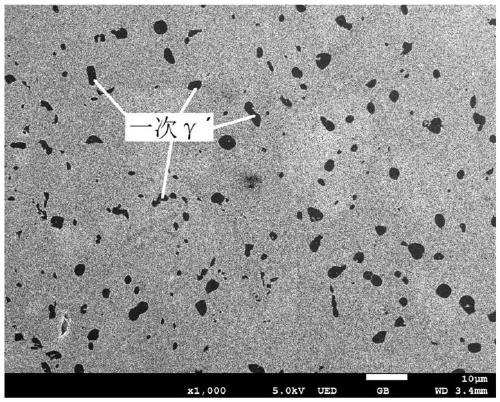

[0060] The above-mentioned preparation method is simple, convenient, and easy to implement. There is no harmful phase precipitation in the preparation process to obtain an ideal microst...

Embodiment 1

[0080] The deformed superalloy includes components with the following mass fractions: Co 20.4%; Cr 13.1%; Mo 4.1%; W 2.2%; Al 3.3%; Ti 3.75%; Nb 1.0%; Ta 2.45%; 0.018%; C 0.020%; Zr 0.050%; Hf 0.001%; Y 0; Fe 0.1%;

[0081] The preparation method of deformed superalloy is as follows:

[0082] 1) Raw materials are prepared according to the proportion of each component, and the master alloy electrode rod is smelted in a vacuum induction furnace;

[0083] 2) Electrode rods are head-cut, tail-removed, and polished, followed by electroslag remelting and continuous directional solidification to prepare directional solidified ingots with a diameter of 260mm, and there are no equiaxed grains in the core of the ingot's macroscopic longitudinal low-magnification structure;

[0084] 3) The directionally solidified ingot is subjected to high-temperature homogenization heat treatment, and the homogenization maximum temperature is 1195°C, and it is kept for 12 hours;

[0085] 4) The ingot...

Embodiment 2

[0090] The composition of the deformed superalloy is the same as in Example 1, except that the total content of Ti and Al is 6.5%, and the mass ratio of Ti and Al is 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com