Roll surface repair material of wrapper roll and laser cladding remanufacturing method of wrapper roll

A technology of repairing materials and laser cladding, which is applied in the coating process and coating of metal materials, and can solve the problem of low service life of the roll-helping roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

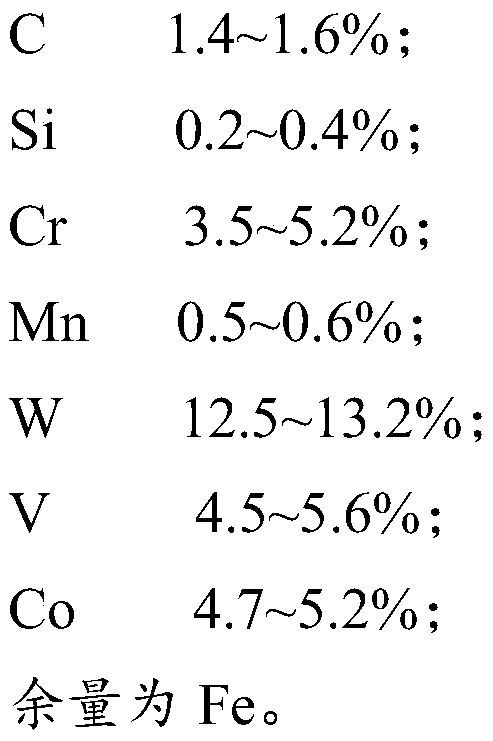

[0049] Prepare the roll surface repair material for the rolling aid roll, in terms of mass percentage, including the following element components: C1.4%; Si0.2%; Cr3.5%; Mn0.5%; W12.5%; V4.5% ; Co4.7%; the balance is Fe, and the particle size of the restoration material is 135-325 mesh.

[0050] The preparation method of the restoration material is the gas atomization method.

[0051] Follow the steps below to remanufacture the laser cladding roll:

[0052] (1) Turning is carried out to the roll surface of roll-assisting roll, and unilateral turning thickness is 1.0mm, and the roll surface after turning is washed and non-destructive testing, and non-destructive testing is qualified, obtains pretreatment roll-helping roll;

[0053] (2) Cladding the roll surface repair material on the surface of the pretreatment roll in step (1) through broadband laser cladding, the broadband spot of laser cladding is a rectangular spot of 1 × 30mm, the laser scanning power is 5600W, and the sc...

Embodiment 2

[0056] Prepare the roll surface repairing material for the rolling aid roll, including the following components in mass percentage: C1.6%; Si0.4%; Cr5.2%; Mn0.6%; W13.2%; V5.6%; Co5.2%; the balance is Fe, and the particle size of the restoration material is 135-325 mesh.

[0057] Follow the steps below to remanufacture the laser cladding roll:

[0058] (1) Turning is carried out to the roll surface of roll-assisting roller, and unilateral turning thickness is 1.2mm, and the roll surface after turning is washed and non-destructive testing, and non-destructive testing is qualified, obtains pretreatment roll-helping roll;

[0059] (2) Cladding the roll surface repair material on the surface of the pretreatment roll in step (1) through broadband laser cladding, the broadband spot of laser cladding is a rectangular spot of 1 × 30mm, the laser scanning power is 6000W, and the scanning speed is 650mm / min, with a lap rate of 10%, the laser cladding remanufacturing roll is obtained, a...

Embodiment 3

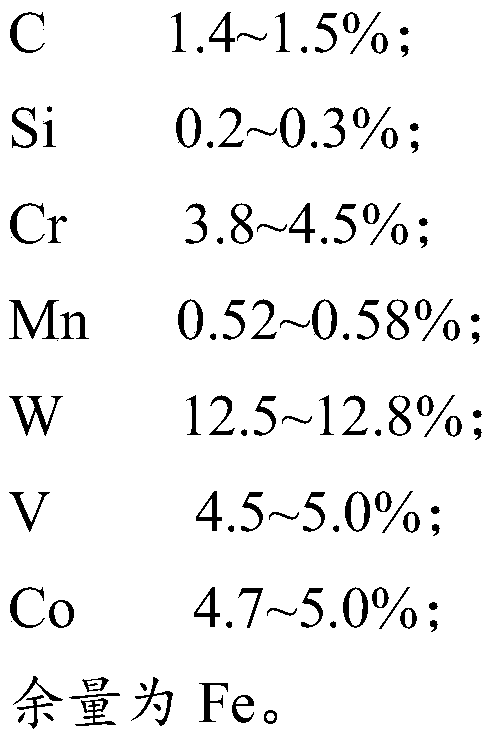

[0062] Prepare the roll surface repair material for the rolling aid roll, including the following components in mass percentage: C1.5%; Si0.3%; Cr3.5%; Mn0.5%; W12.5%; V4.5%; Co4.7%; the balance is Fe, and the particle size of the restoration material is 135-325 mesh.

[0063] Follow the steps below to remanufacture the laser cladding roll:

[0064] (1) Turning is carried out to the roll surface of roll-assisting roll, and unilateral turning thickness is 1.0mm, and the roll surface after turning is washed and non-destructive testing, and non-destructive testing is qualified, obtains pretreatment roll-helping roll;

[0065] (2) Cladding the roll surface repair material on the surface of the pretreatment roll in step (1) through broadband laser cladding, the broadband spot of laser cladding is a rectangular spot of 1 × 30mm, the laser scanning power is 5600W, and the scanning speed is 450mm / min, the overlap rate is 5%, and the laser cladding is obtained to remanufacture the rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com