Microwave drying device

A technology of microwave drying and microwave power, which is applied in the direction of heating device, drying solid materials, heating to dry solid materials, etc., which can solve the problems of large loss, scrapped wafers, and inability to completely remove moisture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

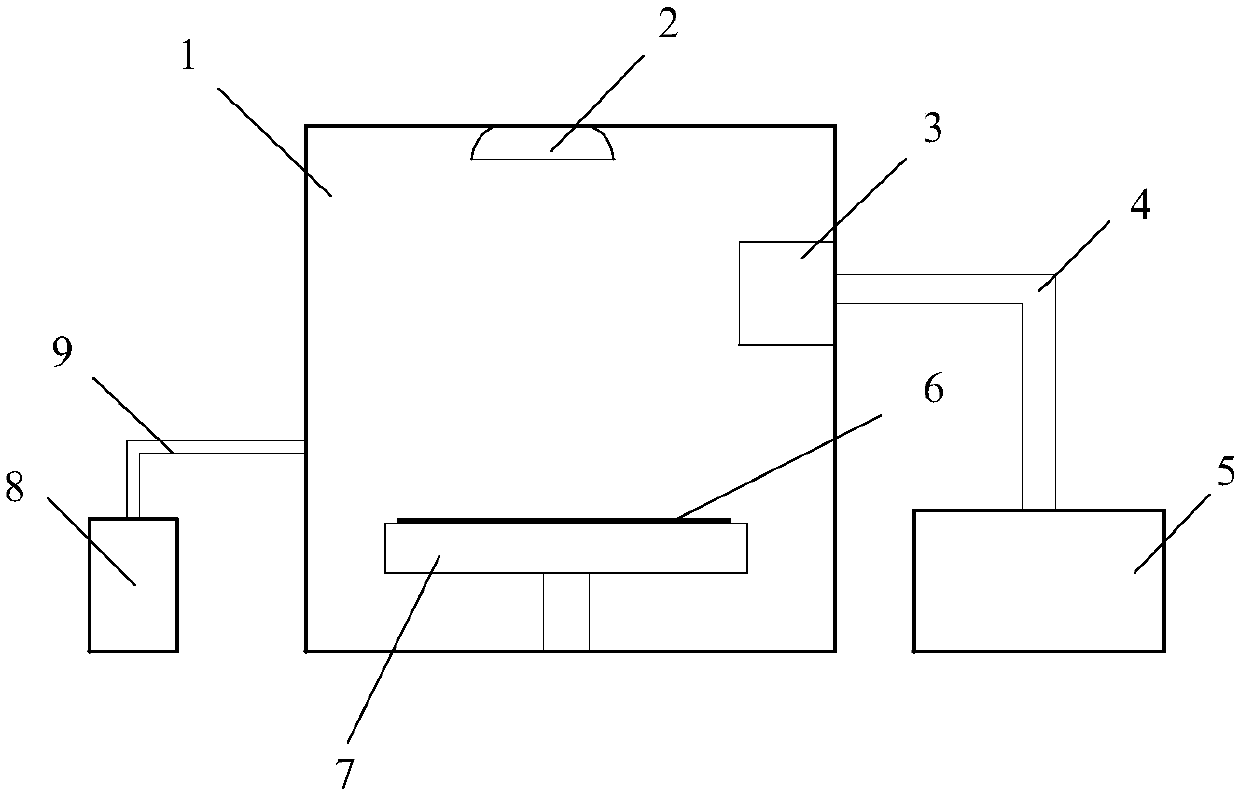

[0014] see figure 1 , a microwave drying device provided by an embodiment of the present invention, including a cavity 1, a UV curing lamp 2, a microwave coupler 3, a microwave transmission wire 4, a microwave power source 5, a slide table 7, a wafer 6, and a vacuum pump group 8 and catheter 9.

[0015] Wherein, the cavity 1 is generally made of aluminum material, and pure aluminum or aluminum alloy material can be used.

[0016] On the side wall of the cavity 1, a microwave coupler 3 is arranged, and the microwave power source 5 outside the cavity 1 is connected to the microwave coupler 3 through the microwave transmission wire 4, and the microwave power is delivered to the microwave coupler 3, and the microwave coupling The device 3 includes a microwave antenna for applying microwave power to the inside of the cavity 1 . The frequency range of the microwave power source 5 is 900MHz to 13GHz, preferably 915MHz to 10GHz, especially 915MHz to 3GHz; the rated output power rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com