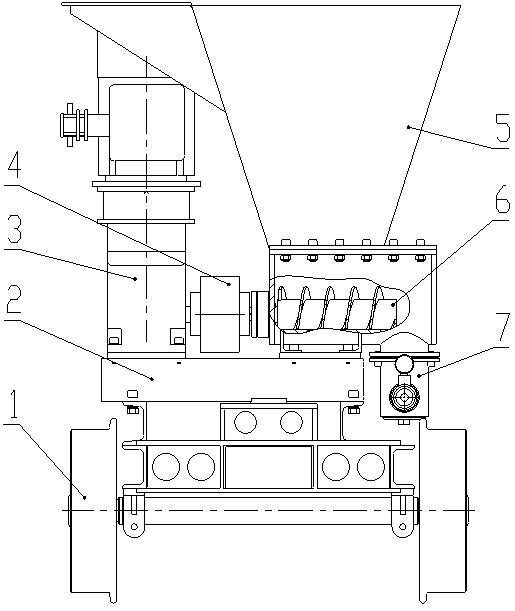

Thin spray sealing material and thin spray sealing method, open powder spraying equipment

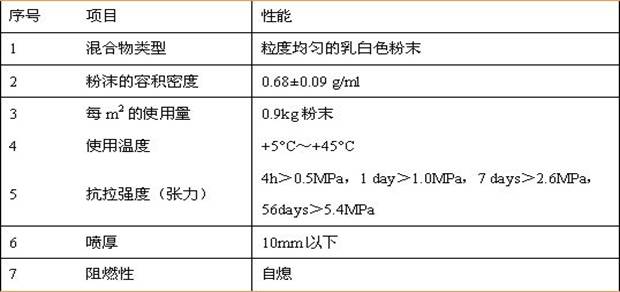

A thin spray, gas material technology, applied in mining equipment, shaft equipment, earthwork drilling and other directions, can solve the problems of unclean operating environment, slow spray speed, easy to break, fall off, etc., to eliminate the generation and stability of bubbles , enhance the densification performance and strength, reduce the effect of particle surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

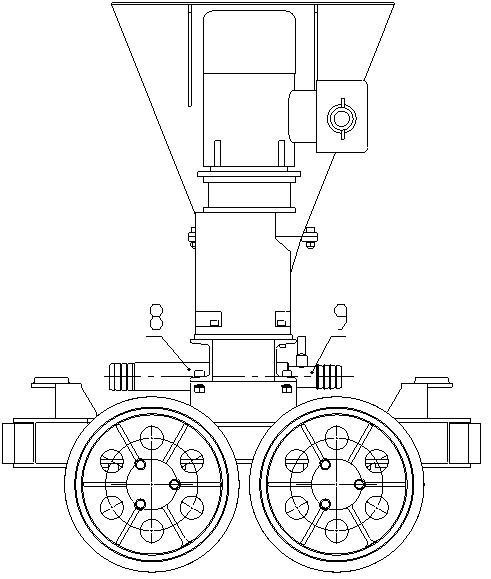

Method used

Image

Examples

Embodiment 1

[0032] The non-reactive powder thin-spray sealing material included in the present invention includes the following components by weight: 55 parts of RD polymer powder, 30 parts of inorganic filler, 14.5 parts of inorganic film-forming agent, and about 0.5 part of auxiliary agent.

[0033] The RD type polymer powder has uniform texture, no agglomeration, no hardening, and can be quickly dispersed in water.

[0034] The above-mentioned inorganic fillers are all stone powder mixtures, and the particle size of the stone powder passes through a 20 mesh (0.9mm) analytical sieve, with uniform color, no gritty feeling, no agglomeration, and no peculiar smell or odor.

[0035] The inorganic film-forming agent includes 5.8 parts of sodium silicate, 5.8 parts of gypsum and 2.9 parts of white cement. The sodium silicate meets the national standard (GB / T 4209-2008), and the gypsum meets the national standard (GB / T 9776 -2008), white cement complies with national preparations (GB 175-2007)...

Embodiment 2

[0046] The non-reactive powder thin spray sealing material included in the present invention includes the following components by weight: 15 parts of RD polymer powder, 60 parts of inorganic filler, 22 parts of inorganic film-forming agent, and about 2 parts of other additives .

[0047] The RD type polymer powder has uniform texture, no agglomeration, no hardening, and can be quickly dispersed in water.

[0048] Among the inorganic fillers, 10 parts are carbon black and 50 parts are stone powder mixture, wherein carbon black complies with the national standard (GB / T3780.10-2009), and the particle size of stone powder is over 20 mesh (0.9mm) analytical sieve, and the color is uniform , no gritty feeling, no agglomeration and peculiar smell, peculiar smell.

[0049] The inorganic film-forming agent includes 6.6 parts of sodium silicate and 15.4 parts of white cement. The inorganic film-forming agent, sodium silicate complies with the national standard (GB / T 4209-2008), and wh...

Embodiment 3

[0053] The non-reactive powder thin-spray sealing material included in the present invention includes the following components by weight: 28 parts of RD polymer powder, 30 parts of inorganic filler, 40 parts of inorganic film-forming agent, and about 2 parts of other additives.

[0054] The RD type polymer powder has uniform texture, no agglomeration, no hardening, and can be quickly dispersed in water.

[0055] The inorganic fillers mentioned above are all carbon black, and the carbon black complies with the national standard (GB / T3780.10-2009), with uniform color, no gritty feeling, no agglomeration, and no peculiar smell or odor.

[0056] The inorganic film-forming agent includes 4 parts of gypsum and 36 parts of white cement. The inorganic film-forming agent mentioned above, gypsum complies with the national standard (GB / T 9776-2008), and white cement complies with the national preparation (GB 175-2007).

[0057] Among the additives mentioned, the defoamer accounts for 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com