A method for preventing the scabbing of the pre-ash bucket in the distillation process in the production of soda ash by the ammonia-soda method

A pre-ash bucket and ammonia-alkali process technology, applied in carbonate preparations and other directions, can solve the problems of reducing system production capacity, production fluctuations, increasing overhaul and maintenance costs, etc., to increase reflux flushing and friction, and improve utilization efficiency. , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

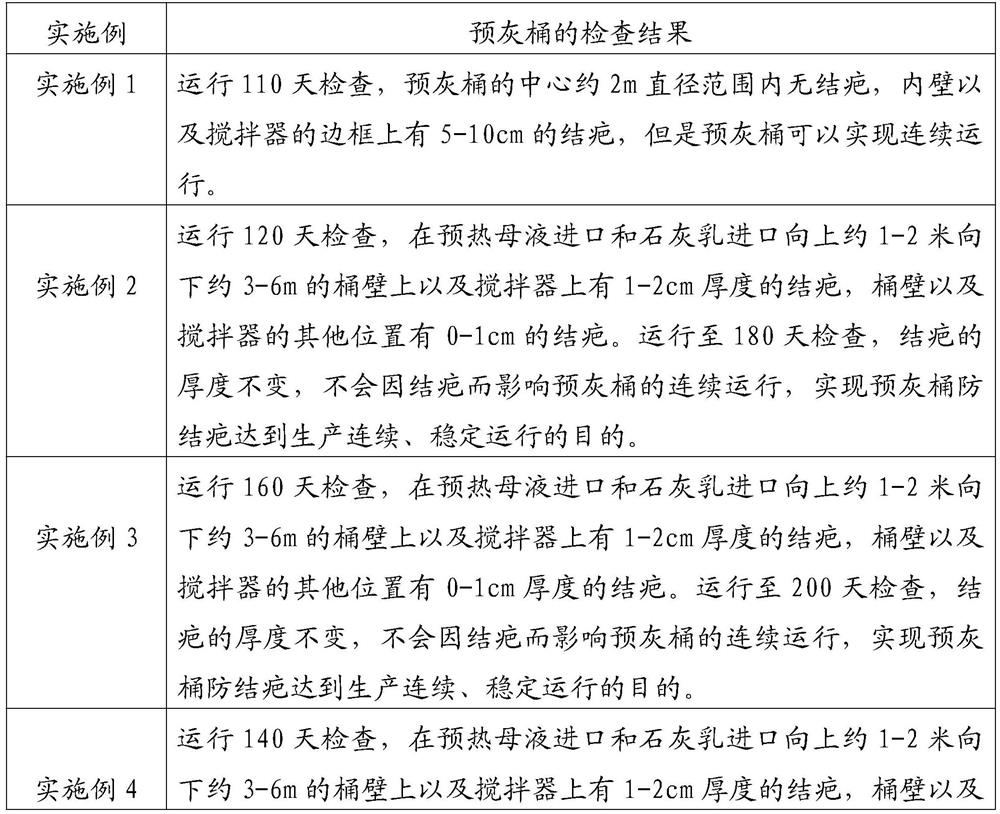

Embodiment 1

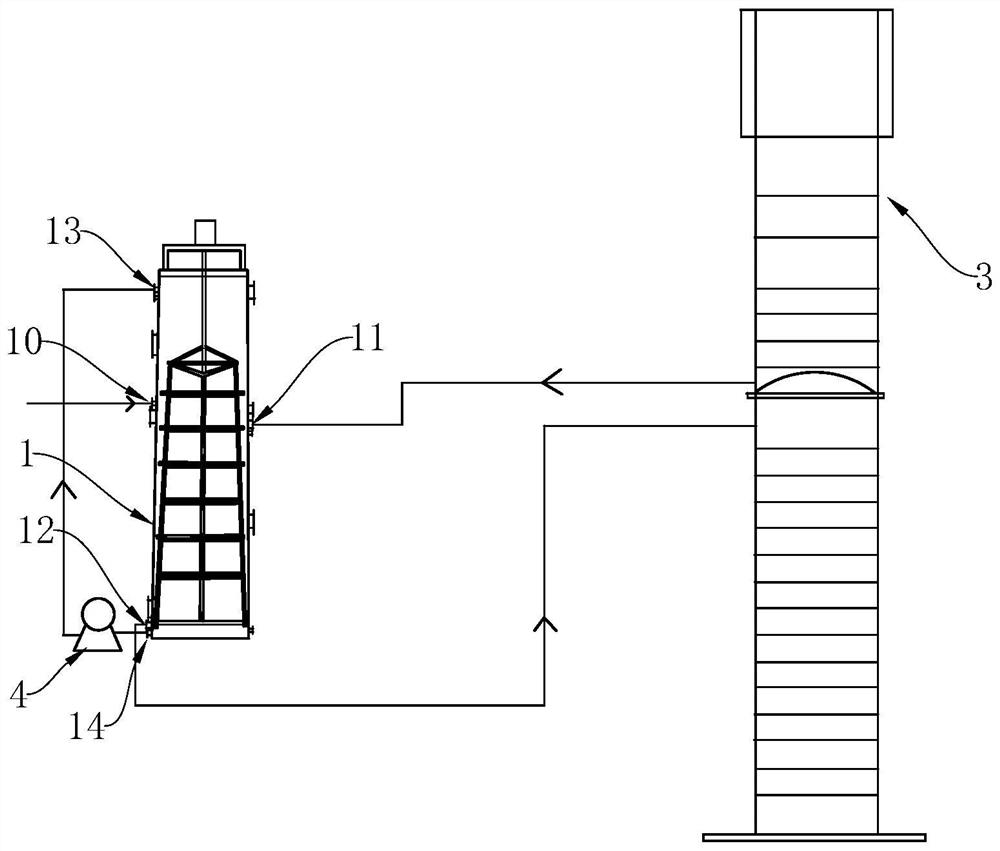

[0025] A method for preventing the scarring of a pre-ash barrel in a distillation process in the production of soda ash by an ammonia-alkali method. A return pipe is arranged on the side of the pre-ash barrel close to the bottom, and the blended liquid that is stirred and mixed by lime milk and preheated mother liquor through the pre-ash barrel is pumped in a reflux pump. Under the action of the return pipe, the turbid liquid returns from the upper part of the pre-ash bucket into the interior of the pre-ash bucket (the return flow of the blending liquid is 360m 3 / h). The distance between the outlet centerline of the return pipe and the bottom of the pre-ash bucket is 12-15cm, and the diameter of the return pipe is 18-22cm.

[0026] The pre-ash barrel includes a barrel, and the upper side of the barrel is provided with a turbid liquid return inlet pipe, the distance between the center line of the turbid liquid return inlet pipe and the top of the barrel is 300cm, and the cente...

Embodiment 2

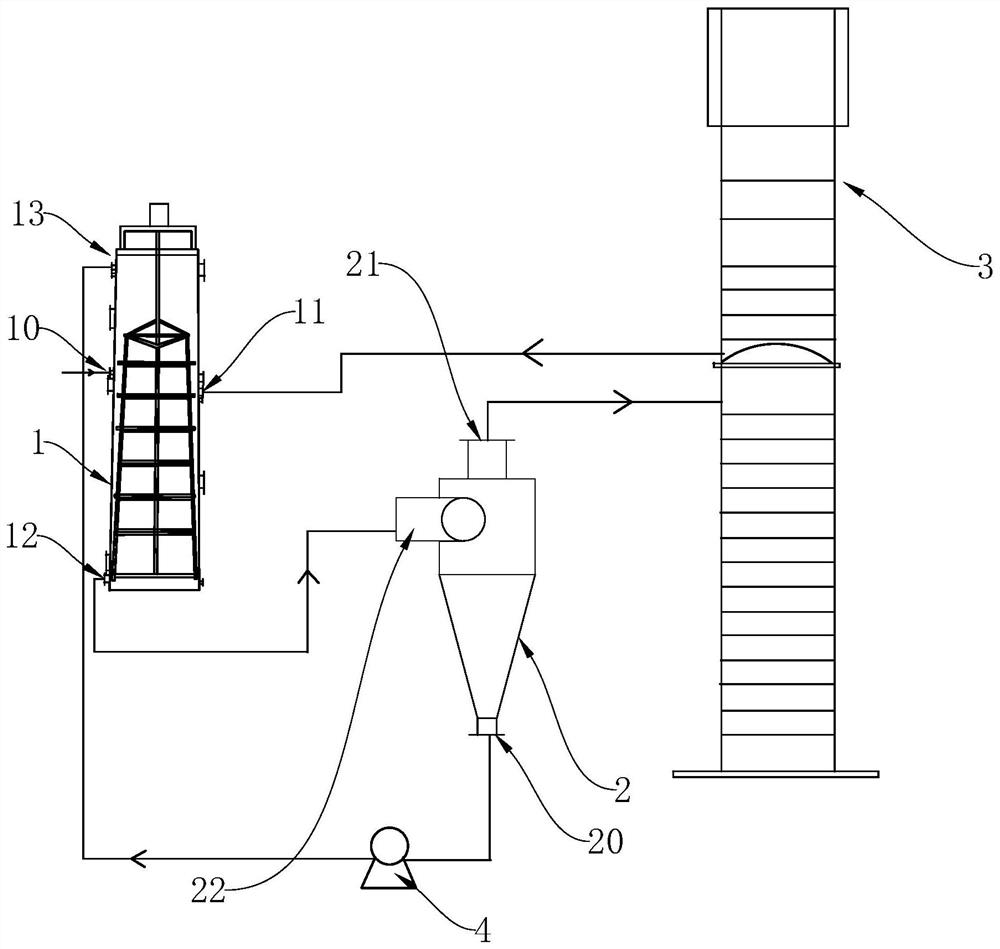

[0029] A method for preventing the scarring of a pre-ash barrel in a distillation process in the production of soda ash by an ammonia-alkali method. The blended liquid that is stirred and mixed by lime milk and pre-heated mother liquor through the pre-ash barrel enters a separator, and the bottom turbid liquid separated by the separator passes through a reflux pump. (The return flow is 370m 3 / h) The turbid liquid reflux inlet pipe set on the upper part of the pre-ash barrel enters the interior of the pre-ash barrel, and the supernatant liquid separated by the separator enters the distillation column.

[0030]The separator includes a body made of carbon steel, and the body includes a straight barrel section and a cone barrel section that are integrally structured and connected to each other. The height ratio of the straight barrel section and the cone barrel section is 2:3; the top center of the straight barrel section is provided with an upper The clear liquid outlet, the upp...

Embodiment 3

[0034] A method for preventing the scarring of a pre-ash barrel in a distillation process in the production of soda ash by an ammonia-alkali method. The blended liquid that is stirred and mixed by lime milk and pre-heated mother liquor through the pre-ash barrel enters a separator, and the bottom turbid liquid separated by the separator passes through a reflux pump. (The return flow is 370m 3 / h) The turbid liquid reflux inlet pipe set on the upper part of the pre-ash barrel enters the interior of the pre-ash barrel, and the supernatant liquid separated by the separator enters the distillation column.

[0035] The separator includes a body made of carbon steel, and the body includes a straight barrel section and a cone barrel section that are integrally structured and connected to each other. The height ratio of the straight barrel section and the cone barrel section is 2:3; the top center of the straight barrel section is provided with an upper The clear liquid outlet, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com