Mask plate and exposure method

An exposure method and mask technology, which are applied in the field of semiconductor manufacturing, can solve the problems of limited exposure field of view and reduced exposure efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

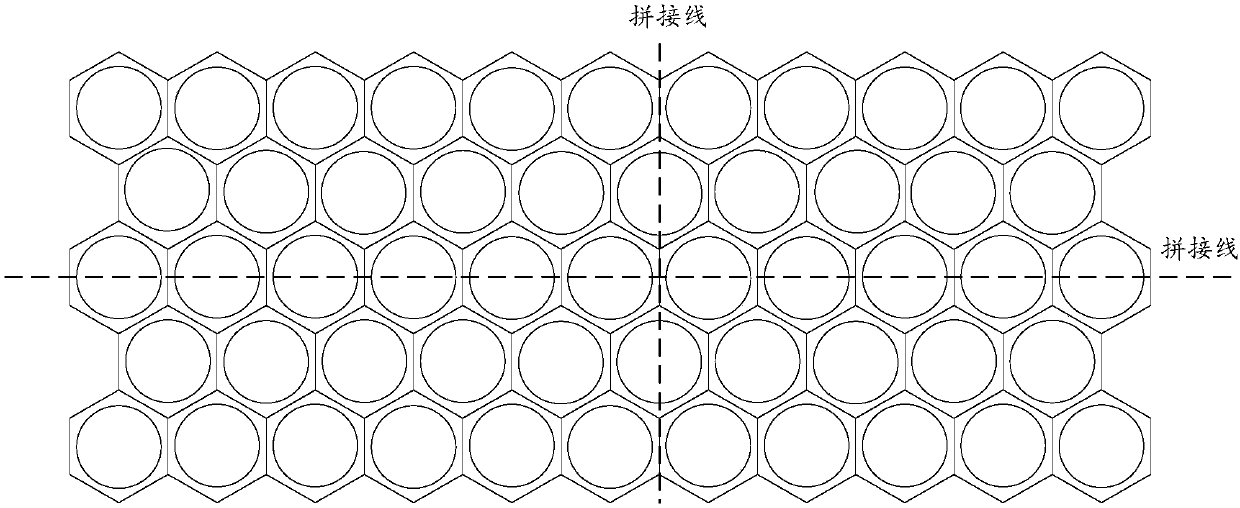

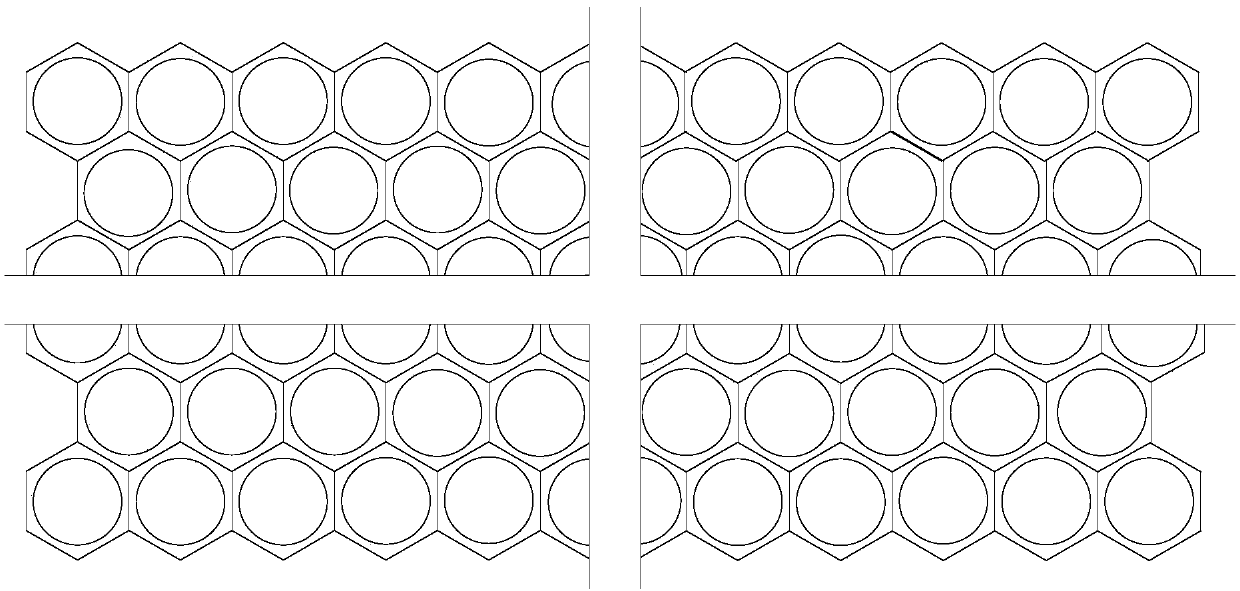

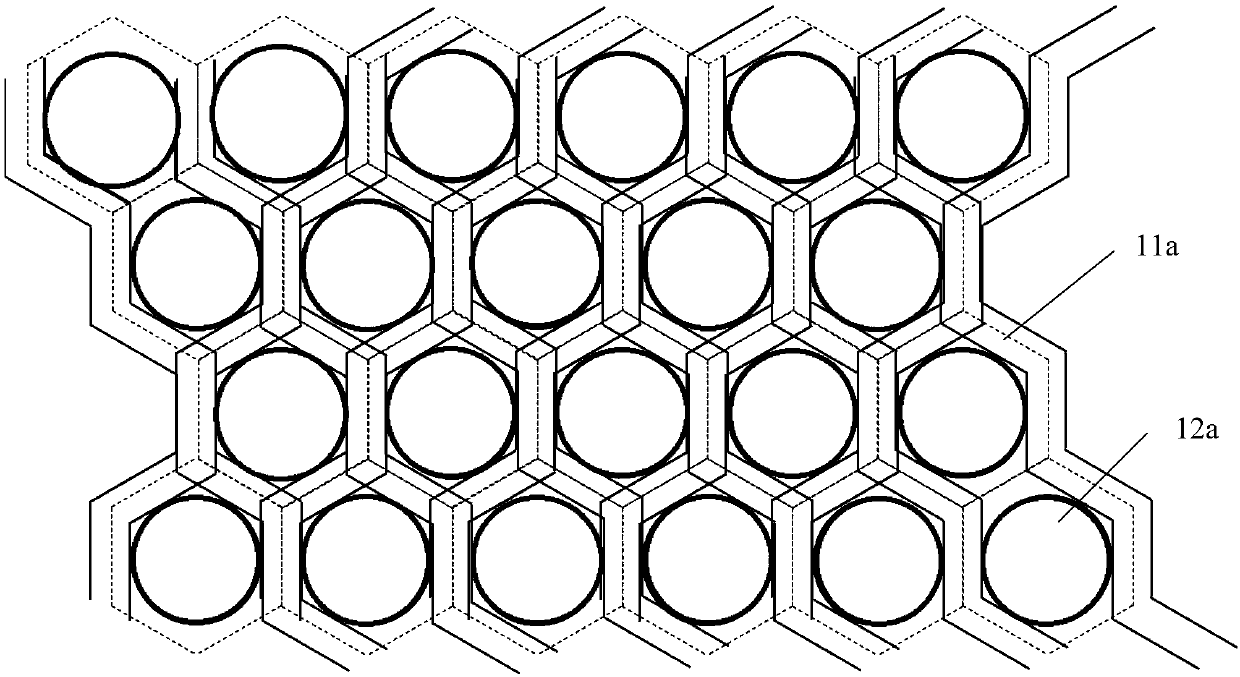

[0041] Such as image 3 As shown, the PSS pattern is a plurality of hexagons arranged in a honeycomb shape, the circular part protrudes to form a protruding part 12a, and the rest part is recessed downward to form a concave part 11a, and several protruding parts 12a are independent of each other, and each The protrusions 12a are all surrounded by the recesses 11a. When preparing the PSS pattern, the protruding portion 12a corresponds to the non-exposed area, and the depressed portion 11a corresponds to the exposed area. The inventors found that the exposure area of the PSS pattern can be disassembled into two groups of line mirror symmetrical figures, and the boundary of each set of figures is the tangent line of the circular non-exposed area, so the overlapping exposure method can be used to form the PSS figure.

[0042] Based on this, the present invention provides a mask plate and an exposure method, including a complementary first mask pattern and a second mask pattern,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com