Quantum dot light-emitting diode and its preparation method

A quantum dot light-emitting and diode technology, which is used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as carrier injection imbalance, increase surface work function, injection balance, and improve hole injection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

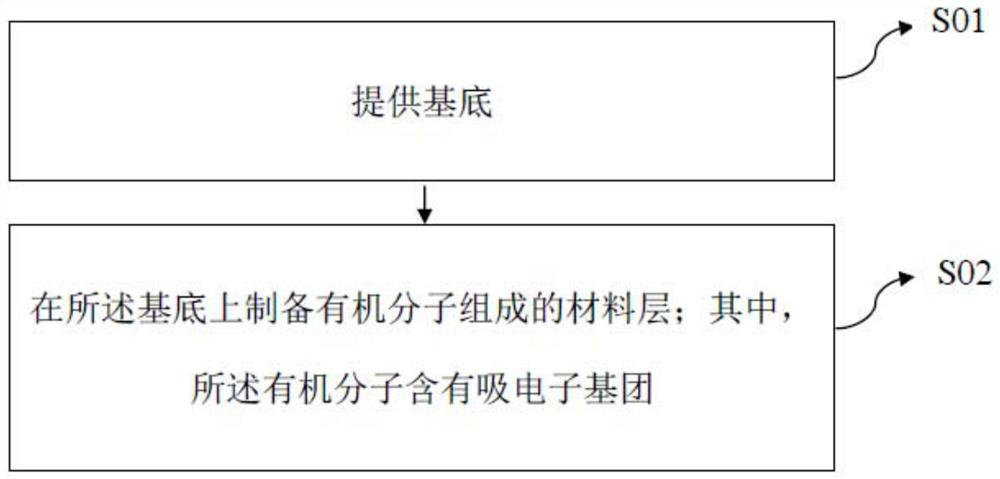

[0029] On the other hand, the embodiment of the present invention also provides a method for preparing a quantum dot light-emitting diode, such as figure 2 shown, including the following steps:

[0030] S01: Provide a base;

[0031] S02: Prepare a material layer composed of organic molecules on the substrate; wherein, the organic molecules contain electron withdrawing groups.

[0032]The preparation method of the quantum dot light-emitting diode provided by the embodiment of the present invention is simple in process and low in cost, and the device can be obtained by directly preparing a material layer composed of unique organic molecules on the substrate; the material in the device finally obtained by the preparation method The layer is between the anode and the quantum dot light-emitting layer, and is a material layer made of organic molecules containing electron withdrawing groups. Such organic molecules can increase the surface work function of the anode material and red...

Embodiment 1

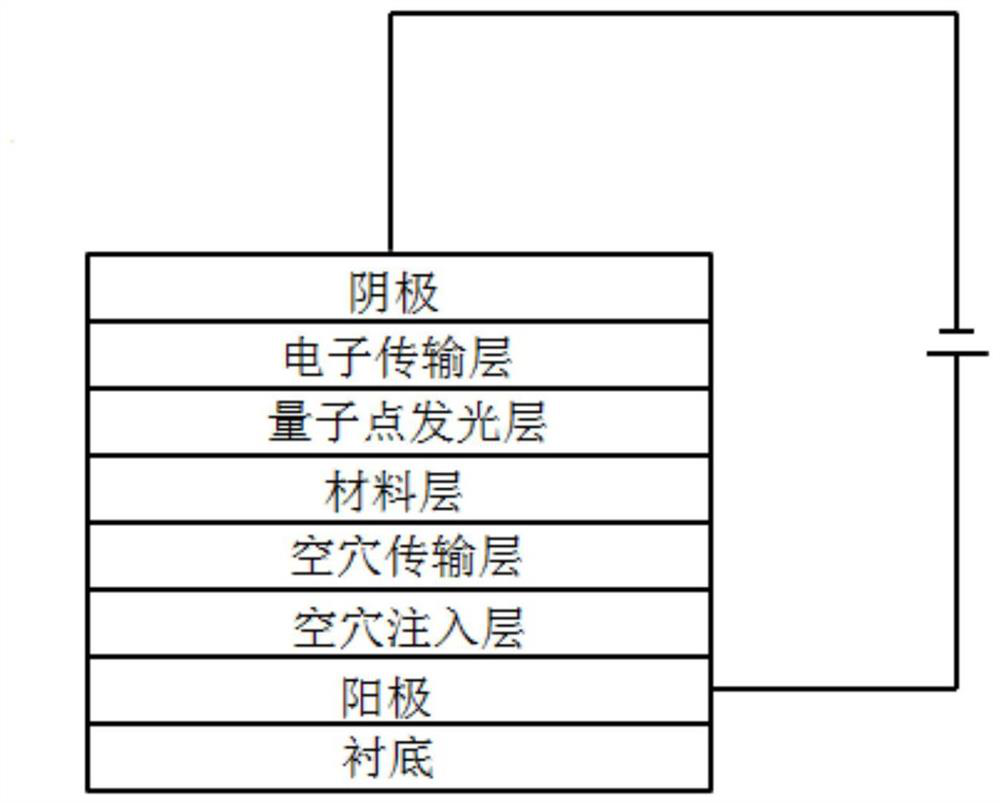

[0044] A kind of QLED light-emitting device, its structure diagram is as follows figure 1 As shown, from bottom to top, it includes a substrate, an anode disposed on the substrate, a hole injection layer disposed on the anode, a hole transport layer disposed on the hole injection layer, and a hole transport layer disposed on the hole transport layer A material layer consisting of 4-nitrothiophenol, a quantum dot light-emitting layer arranged on the material layer, an electron transport layer arranged on the quantum dot light-emitting layer, a cathode arranged on the electron transport layer, arranged between the anode and the cathode the encapsulation layer.

[0045] in,

[0046] In this embodiment, the substrate adopts a glass substrate;

[0047] In this embodiment, the anode is ITO with a thickness of 150 nm. To take out ITO, first use a nitrogen gun to clear the large particles of dust on the surface, then use detergent, ultrapure water, and isopropyl alcohol to ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com