Hydrophobic graphdiyne composite iron-containing MOF adsorbent and preparation method thereof

A graphdiyne and adsorbent technology is applied in the field of preparation of highly hydrophobic graphdiyne composite adsorbents, which can solve the problems of MOFs skeleton collapse, reduce MOFs adsorption of VOCs, etc. The effect of water performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

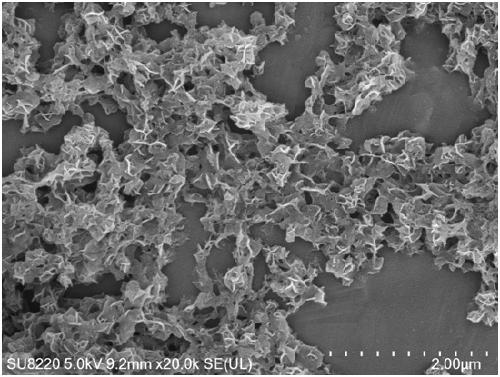

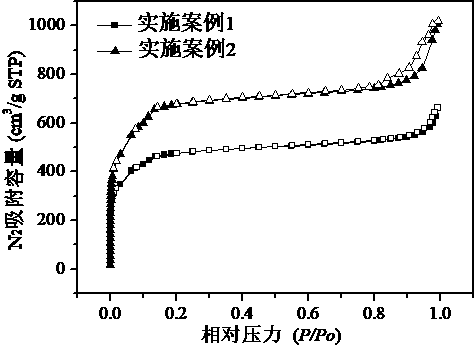

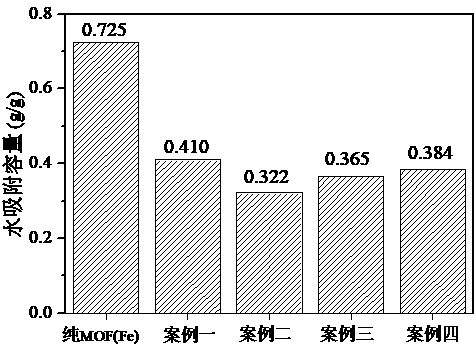

[0039] A preparation method of a hydrophobic graphyne composite iron-containing MOF adsorbent, comprising the steps of,

[0040] (1) Preparation of MOF(Fe) seed crystals: first, ultrasonically disperse 1.0mmoL trimesic acid and 1.0mmoL ferric nitrate nonahydrate in an aqueous solution, and then place them in a stirrer to stir, (ferric nitrate nonahydrate and trimesis The molar ratio of acid is (1:1)). The solution was then put into a high-pressure reactor and placed in a programmed oven, and the temperature was raised to 150° C. at a rate of 10° C. / min for another 24 hours. The obtained MOF(Fe) material is ground to a particle size of <1.0 μm. Recorded as MOF(Fe) seed crystal.

[0041] (2) Preparation of MOF(Fe) seed crystal Pickering emulsion: first, place the ground MOF(Fe) seed crystal in the aqueous solution to obtain solution A: the input quality of the MOF(Fe) seed crystal is 2 mg, and the aqueous solution The total volume is 20mL; configure copper acetate aqueous sol...

Embodiment 2

[0045] A preparation method of a hydrophobic graphyne composite iron-containing MOF adsorbent, comprising the steps of,

[0046] (1) Preparation of MOF(Fe) seed crystals: first, ultrasonically disperse 1.0mmoL trimesic acid and 1.78mmoL ferric nitrate nonahydrate in aqueous solution, and then place them in a stirrer to stir, (ferric nitrate nonahydrate and tribenzene The molar ratio of the triacids is 1:1.78). The solution was then put into a high-pressure reactor and placed in a programmed oven, and the temperature was raised to 150° C. at a rate of 2° C. / min for another 24 hours. The obtained MOF(Fe) material is ground to a particle size of <1.0 μm. Recorded as MOF(Fe) seed crystal.

[0047] (2) Preparation of MOF(Fe) seed crystal Pickering emulsion: first, place the ground MOF(Fe) seed crystal in the aqueous solution to obtain solution A: the input quality of the MOF(Fe) seed crystal is 100mg, and the aqueous solution The total volume is 100mL; configure copper acetate a...

Embodiment 3

[0051] A preparation method of a hydrophobic graphyne composite iron-containing MOF adsorbent, comprising the steps of,

[0052] (1) Preparation of MOF(Fe) seed crystals: First, 1.0mmoL trimesic acid and 1.6mmoL ferric nitrate nonahydrate were ultrasonically dispersed in an aqueous solution (the molar ratio of ferric nitrate nonahydrate to trimesic acid was 1:1.6) , and then stirred in a blender. Then put the solution into a high-pressure reactor and place it in a programmed oven, and raise the temperature to 100° C. at a rate of 2° C. / min and keep the reaction for 20 hours. The obtained MOF(Fe) material is ground to a particle size of <1.0 μm. Recorded as MOF(Fe) seed crystal.

[0053] (2) Preparation of MOF(Fe) seed crystal Pickering emulsion: first put the ground MOF(Fe) seed crystal into the aqueous solution to obtain solution A: the input quality of the MOF(Fe) seed crystal is 70mg, and the aqueous solution The total volume is 80mL; configure copper acetate aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com