Automatic cleaning and water saving device for electroplating production and cleaning method

A water-saving device and automatic cleaning technology, applied in the direction of cleaning methods using gas flow, cleaning methods and utensils, and cleaning methods using liquids, can solve problems such as recycling, unreasonable cleaning water, and waste of water resources, and achieve Reduce workload, increase stability and intelligence, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

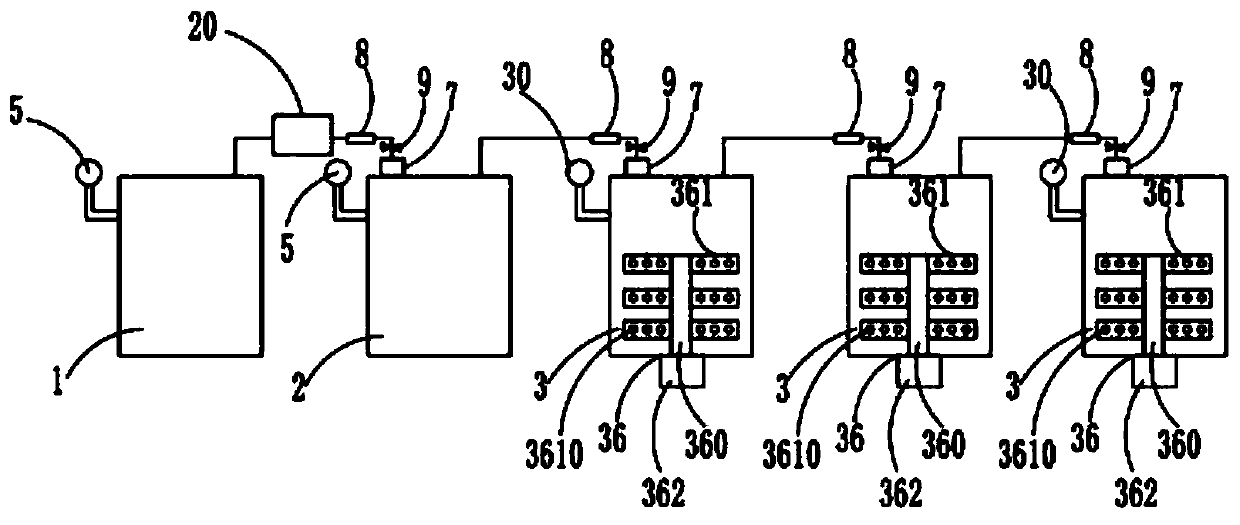

[0037] Such as figure 1 The shown automatic cleaning and water-saving device for electroplating production mainly includes a plating tank 1, a recovery tank connected with the plating tank 1 and a condensing evaporator 20 at the connection part 2, three successively connected cleaning tanks 3, and various electrical PLC automatic control system 4 with electrical connection of components;

[0038] The plating tank 1 and the recovery tank 2 are equipped with level gauges 5, the recovery tank 2 and the three cleaning tanks 3 are equipped with spray devices 6, and the cleaning tanks 3 on both sides are respectively equipped with conductivity meters 30, Among them, the level meter 5 is a SIN-DP ultrasonic level meter, and the conductivity meter 30 is a CCT-5300E5310E5320E5320 series conductivity meter;

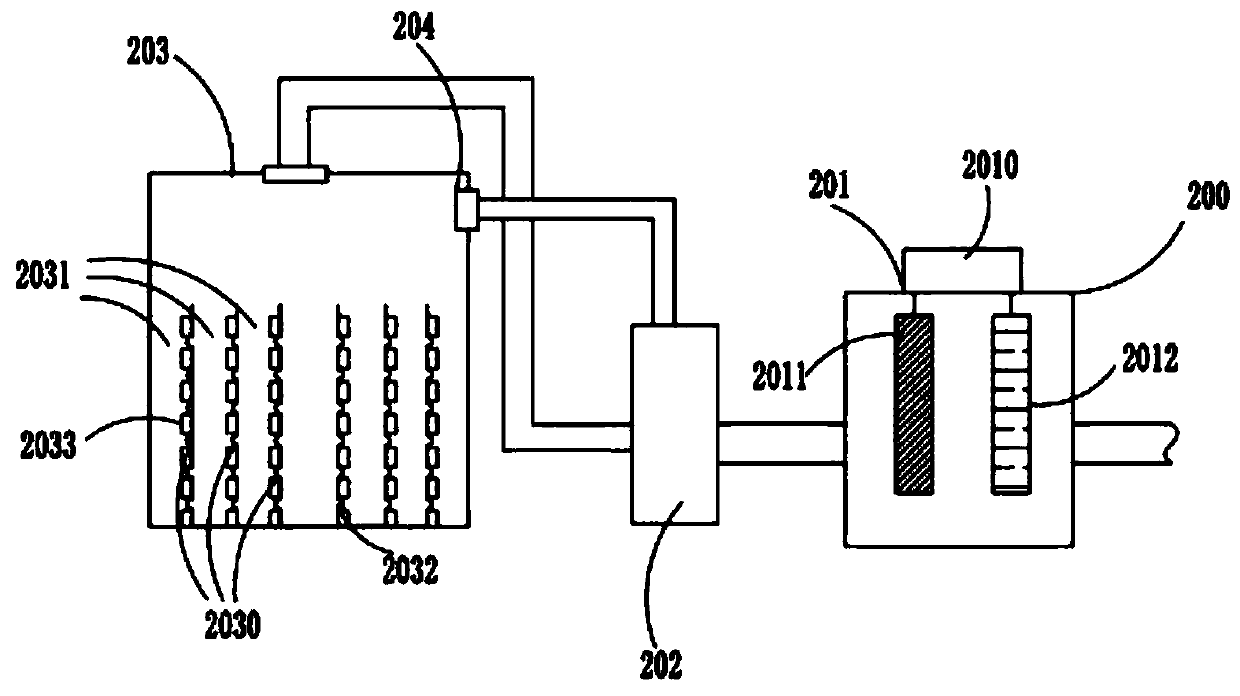

[0039] Such as figure 2 As shown, the concentration evaporator 20 includes a weak electrolysis tank 200 connected to the recovery tank 2, a weak electrolysis element 201 provided in th...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, and the difference lies in:

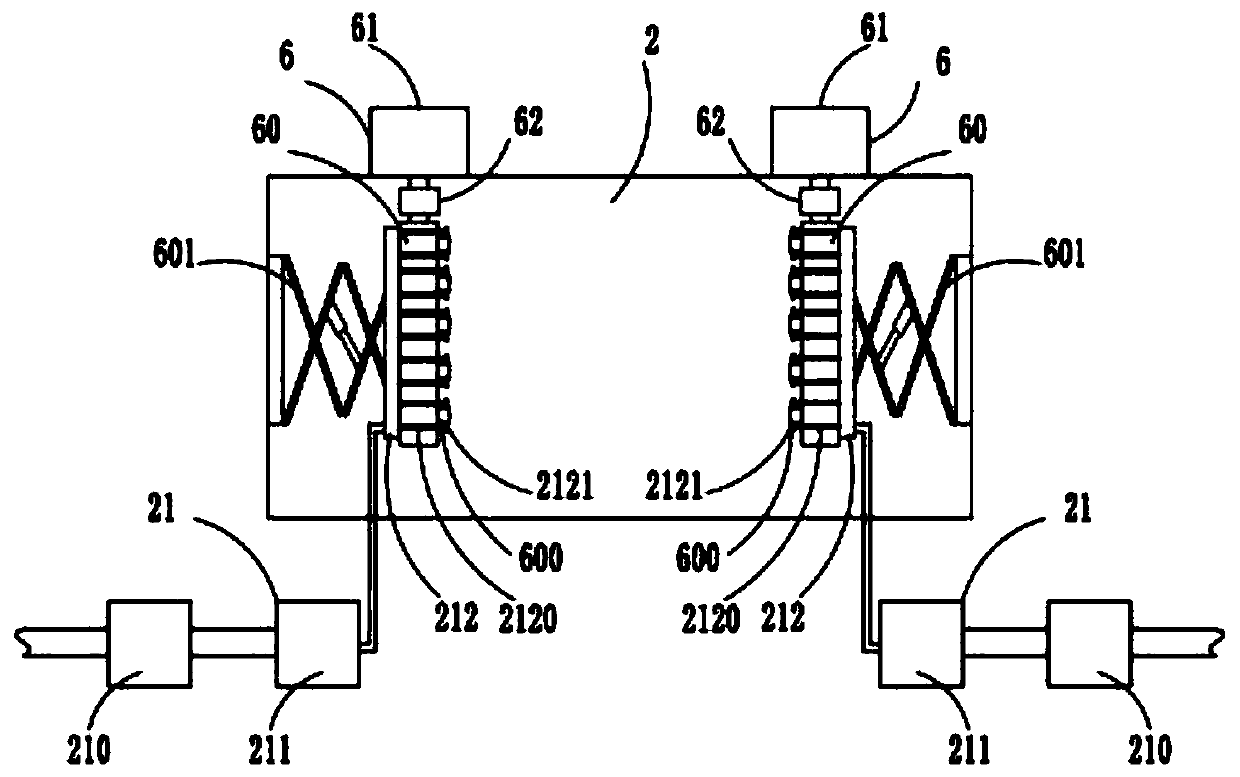

[0044] Such as image 3 As shown, the recovery tank 2 is provided with a high-pressure blow-off device 21. The high-pressure blow-off device 21 includes a filter 210 that filters external air, a high-pressure suction pump 211 connected to the filter 210 through a connecting pipe, and one end and a high-pressure suction pump 211 is connected and the other end is provided with 30 air jet plates 212 that penetrate the spray buckle 60 and extend to the outside of the branch pipe 2120. The 30 branch pipes 2120 are provided with multiple air nozzles 2121 at the end, and two 30 air nozzles 2121 are one. It is arranged around the periphery of each atomizing nozzle 600, and the liquid and electroplating liquid carried by each atomizing nozzle 600 are sprayed to the surface of the plated part through the pure high-pressure gas of the air nozzle 2121, thereby reducing the subsequent cleaning water con...

Embodiment 3

[0046] This embodiment is basically the same as embodiment 2, except for the following:

[0047] Such as Figure 5 As shown, the cleaning tank 3 includes a cleaning inner wall 32, a cleaning outer wall 33, and a constant temperature heater 34 arranged outside the cleaning inner wall 32. A heating and heat preservation cavity 35 is formed between the cleaning inner wall 32 and the cleaning outer wall 33, and the inner wall of the heating and heat preservation cavity 35 is attached The insulation layer 350 is heated by the constant temperature heater 34 for the cleaning liquid in each cleaning tank 3 to increase the cleaning effect, improve the cleaning efficiency, and increase the reliability of the device. The insulation layer 350 is made of rubber-plastic insulation material, rubber-plastic insulation The material is made of elastic closed-cell elastic material, which is cold-resistant, heat-resistant, flame-retardant, waterproof, and has excellent performance with low thermal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com