Laser additive manufacturing and laser micro-nano processing integrated device and method

A micro-nano processing and laser additive technology, applied in additive processing, solid material additive processing, processing and manufacturing, etc., can solve the problems of difficult and precise positioning, high cost, difficulty, etc., and achieve precise positioning and control, design and Simple, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

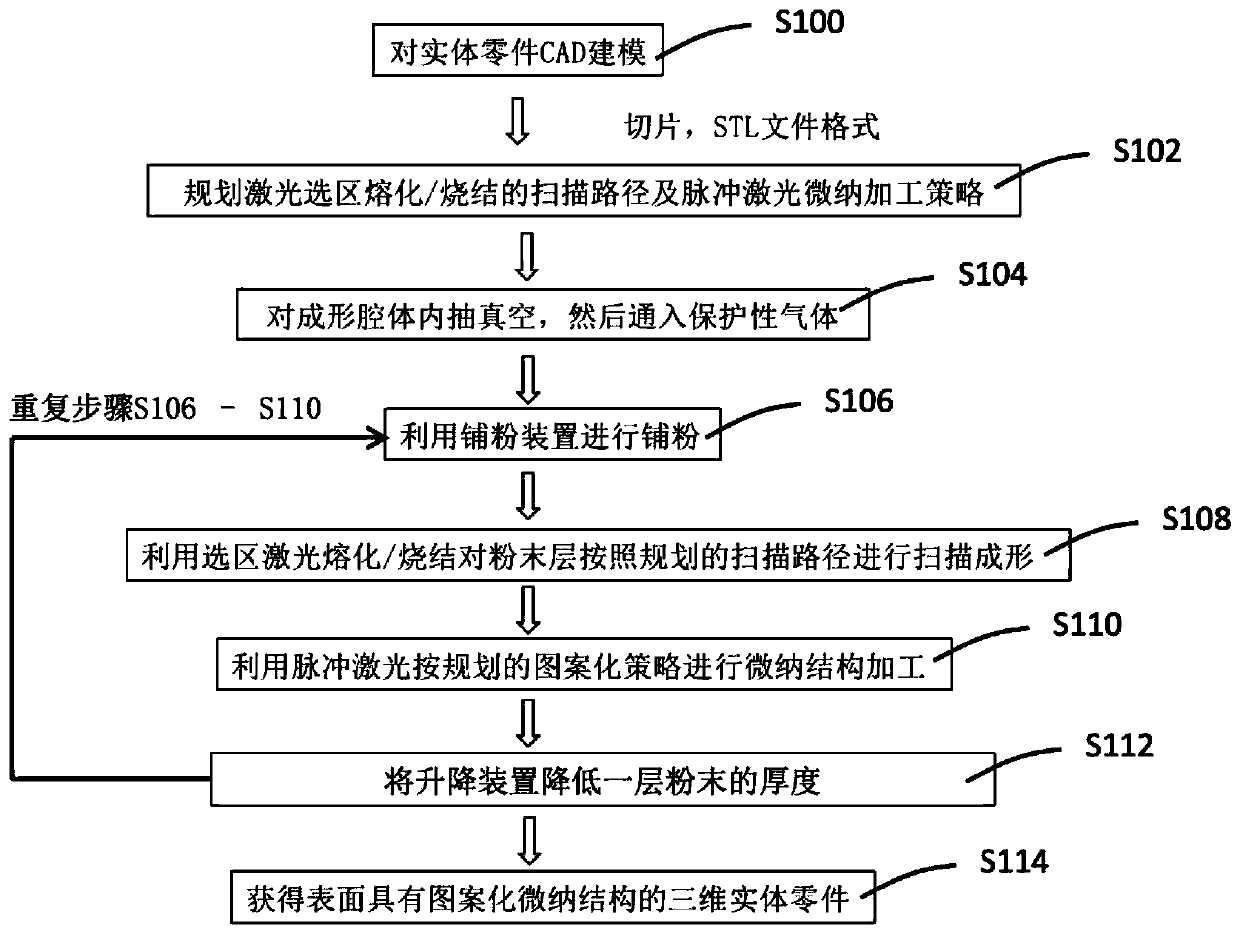

[0046] like figure 1 shown. An integrated method of laser additive manufacturing and laser micro-nano processing comprises the following steps:

[0047] (1) According to the solid part, establish its geometric model, slice the geometric model to make it discretized, and generate STL (STereoLithography, stereolithography) format file (S100);

[0048] (2) Planning a scanning strategy for selective laser melting / sintering (including, for example, a scanning path) and a strategy for laser micro-nano-machining patterning ( S102 ).

[0049] (3) Vacuum the inside of the forming cavity (also referred to as "printing cavity"), and then pass in protective gas (S104);

[0050] (4) Utilize the powder spreading device to carry out powder spreading (S106);

[0051] (5) Scanning and forming the powder layer according to the scanning path planned in step S102 by using selective laser melting / sintering to obtain the current forming layer (S108);

[0052] (6) For the sidewall of the front ...

Embodiment 2

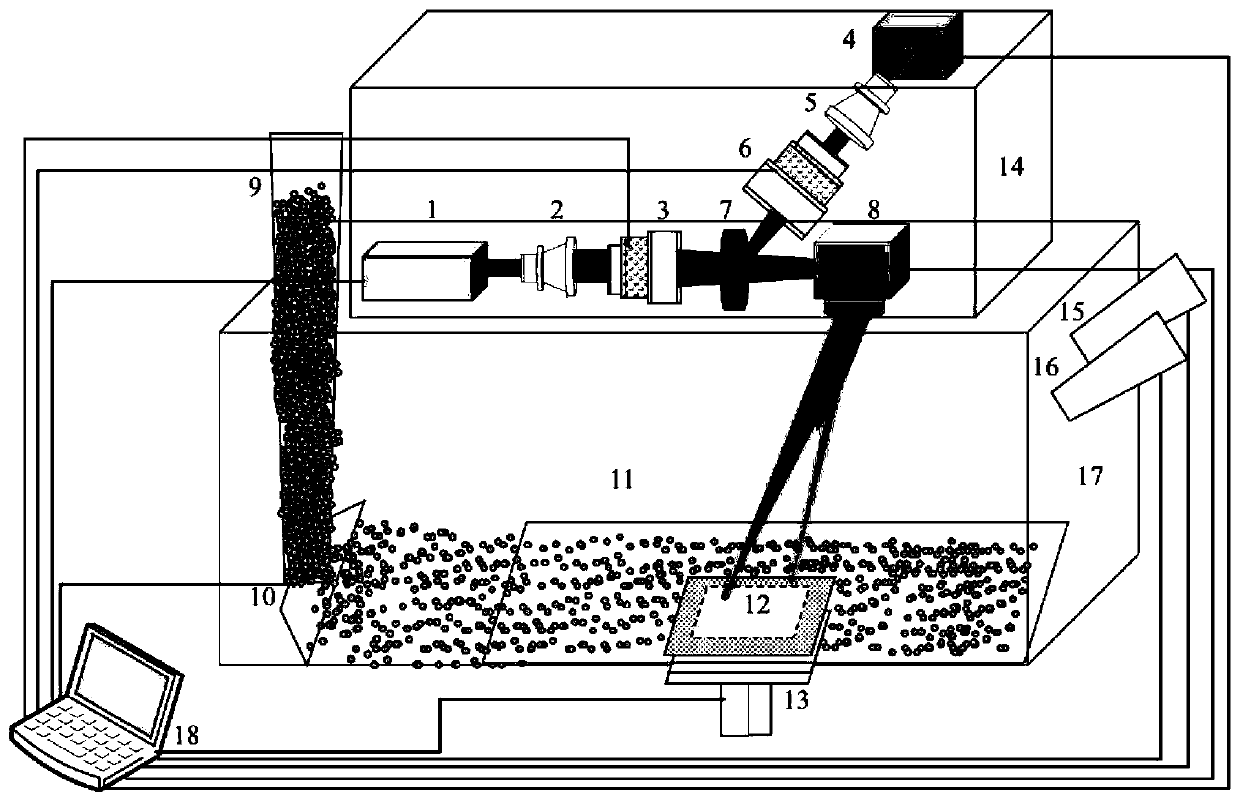

[0060] like image 3 shown. A device combining laser additive manufacturing and laser micro-nano processing includes a dual-beam coaxial dynamic focusing scanning system ( image 3 : 2, 3, 5-8), gas control system ( image 3 :15, 16), powder laying system ( image 3 :9-11), mechanical motion system ( image 3 :10, 13), laser selective melting system ( image 3 :1-3, 7, 8), laser micro-nano processing system ( image 3 :4-8), software control system ( image 3 :18).

[0061] (1) a gas control system, the gas control system evacuates the printing chamber 17 and feeds a protective gas (for example, nitrogen);

[0062] (2) Powder laying system for laying powder;

[0063] (3) a mechanical motion system, used to control the lifting of the lifting platform 13 and the operation of the scraper (also referred to as a "powder scraper") 10;

[0064] (4) Dual-beam coaxial dynamic focusing scanning system, used to focus, combine and scan two laser beams with different functions;

...

Embodiment 3

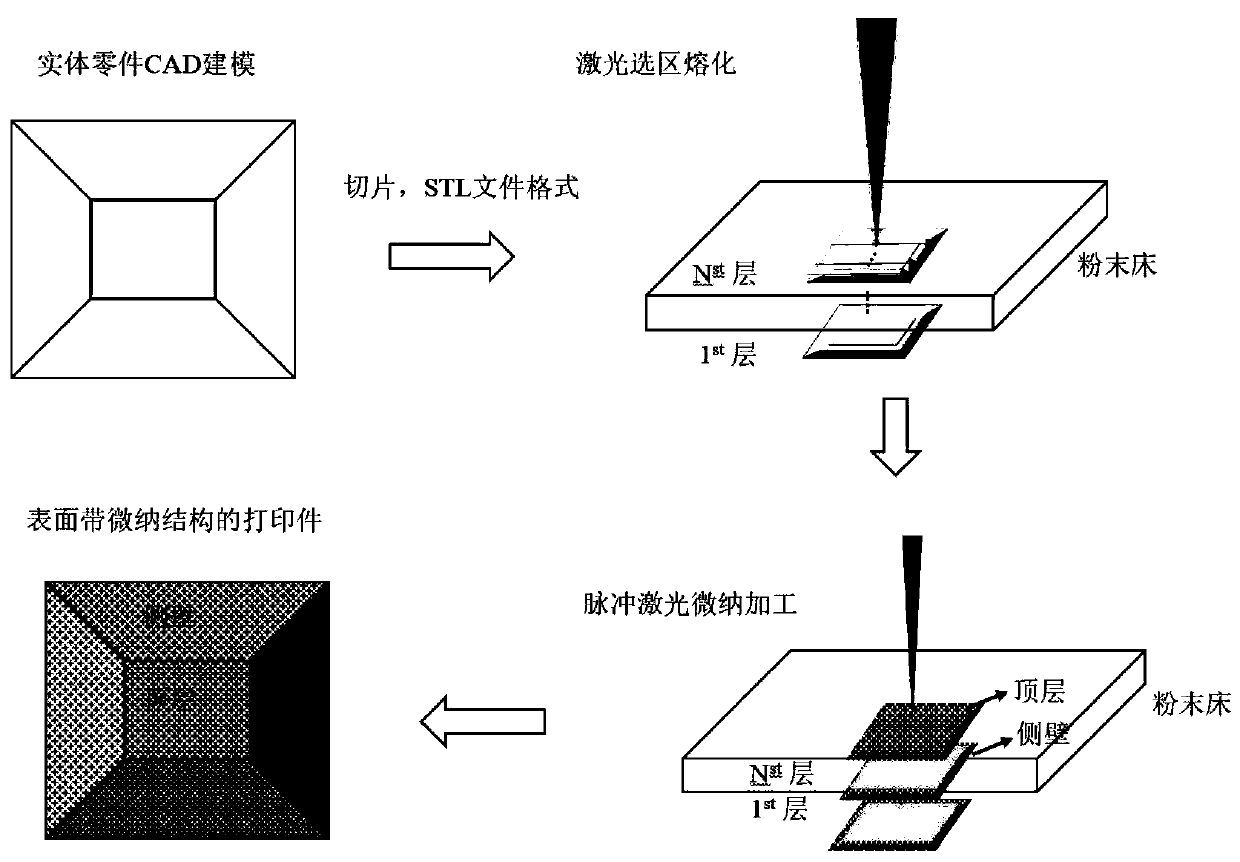

[0071] combine Figure 1-3 In this embodiment, the integrated method of laser additive manufacturing and laser micro-nano processing will be used to manufacture cylinders with a diameter of 15 mm and a height of 5 mm with different optical and surface wetting properties. The specific steps are as follows:

[0072] First of all, choose to put the titanium powder of spherical particles with a diameter of 30-50 μm into the powder storage container 9; use CAD software to build 4 cylinder models with a diameter of 15 mm and a height of 5 mm; then use the slicing software to slice these models ; According to the segmentation results, the path of laser selective melting and the path of laser micro-nano processing are planned, and the relevant programs of programming are input into the computer software control system 18; It can be less than 0.1%; then use the powder scraping device 10 (also known as "powder scraper", "powder scraper") to spread powder on the substrate, the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com