Quick-drying high-solid low-viscosity epoxy paint for engineering machinery and preparation method thereof

A construction machinery, quick-drying technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as unsatisfactory rapid construction, and achieve the effects of improving market competitiveness, strong adhesion, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

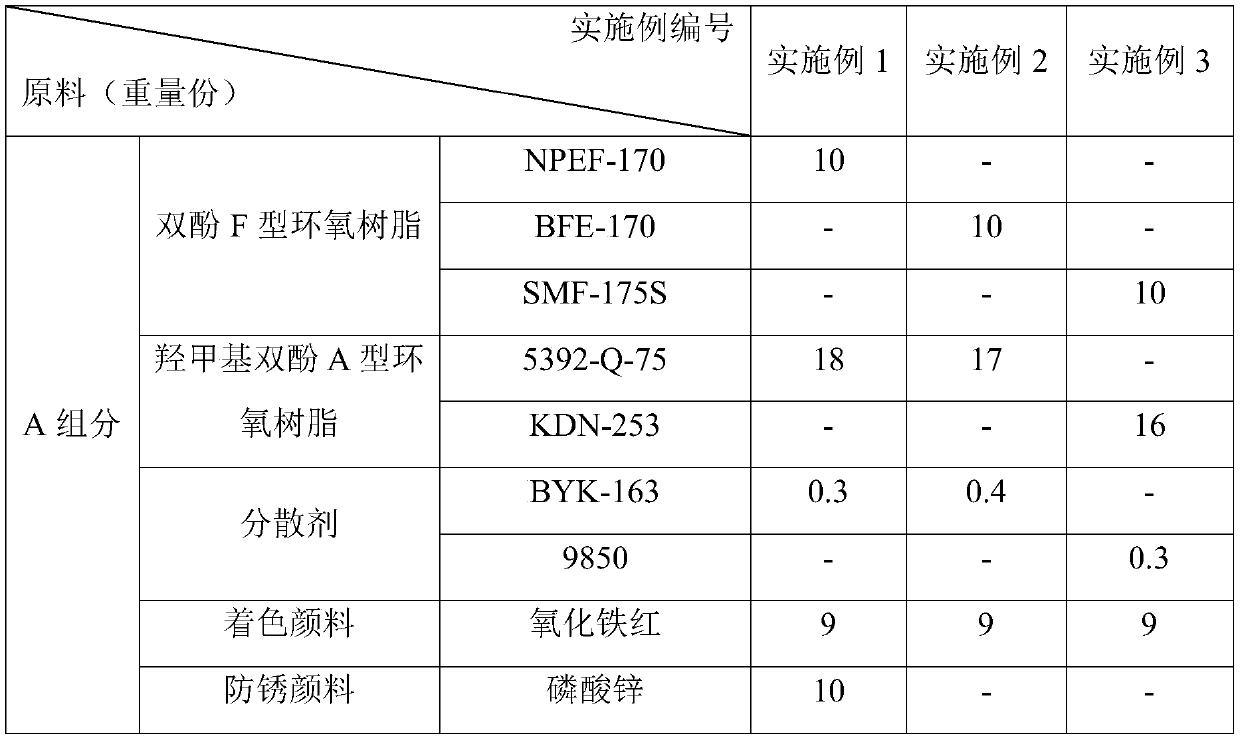

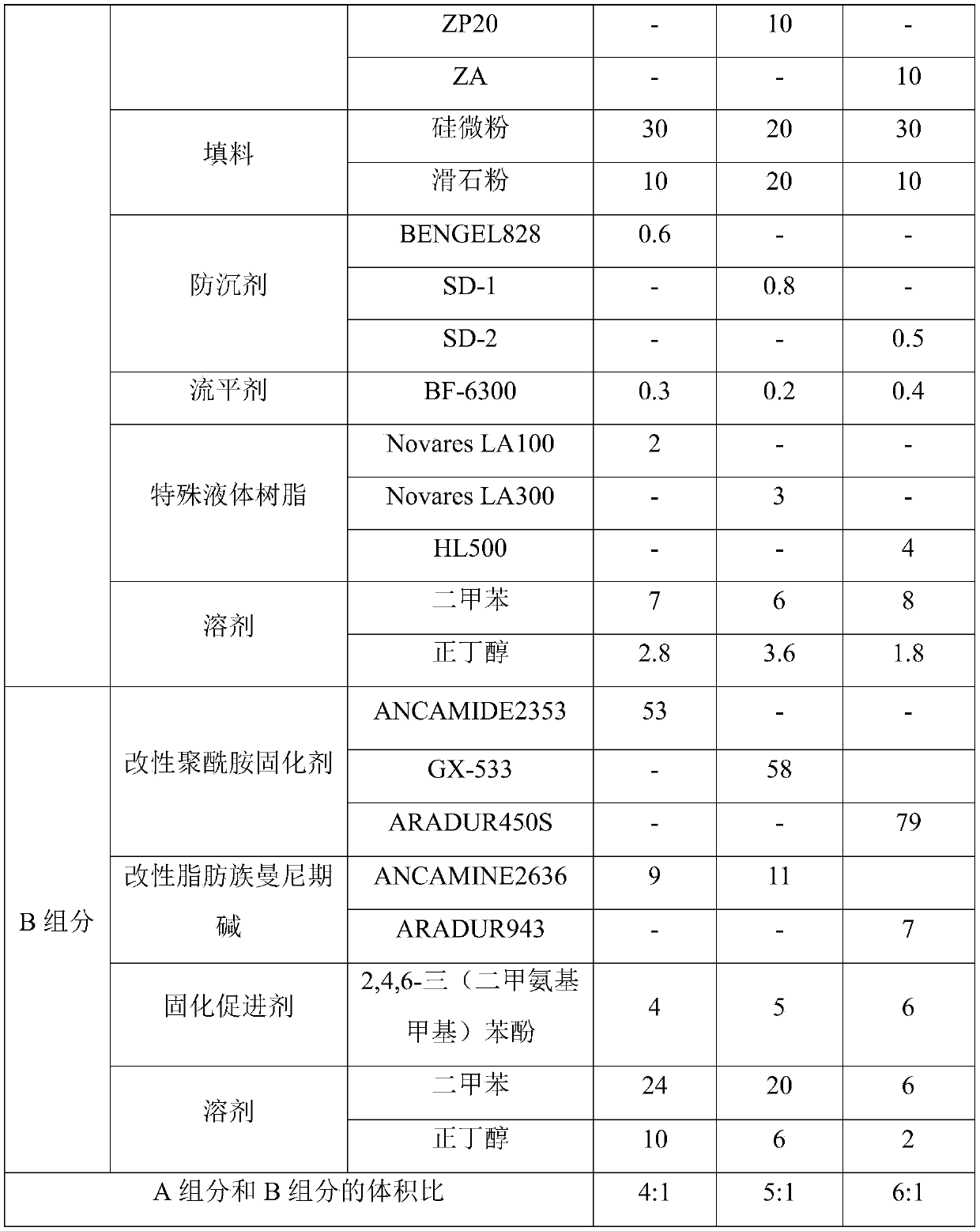

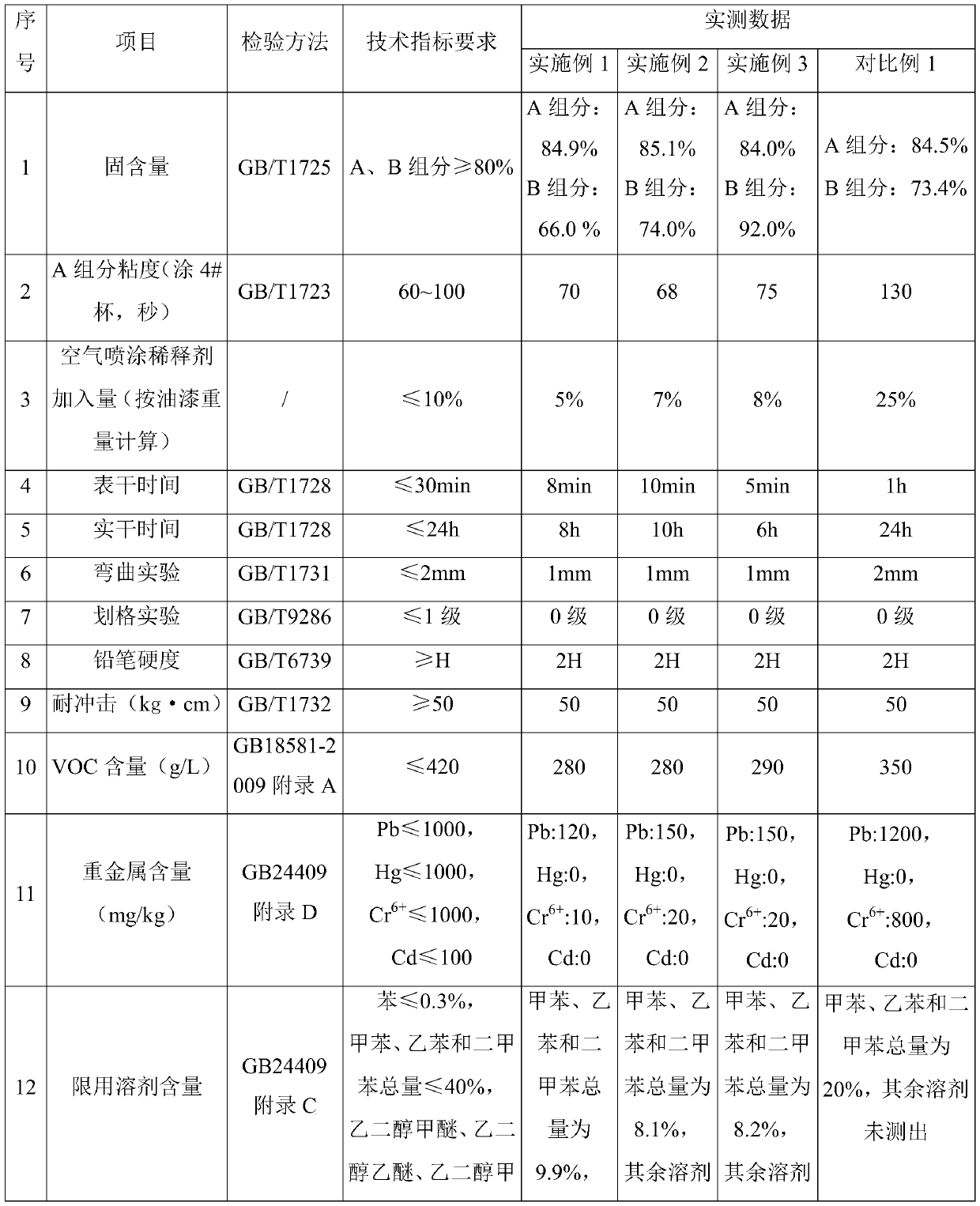

[0040] Examples 1-3 of high-solid and low-viscosity epoxy coatings for fast-drying construction machinery of the present invention

[0041] The parts by weight of each raw material are as shown in table 1: 3

[0042] Table 1 The parts by weight of each raw material in Examples 1 to 3 of the high-solid and low-viscosity epoxy coating for fast-drying engineering machinery of the present invention

[0043]

[0044]

[0045] Note: "-" in the table means not added.

Embodiment 1

[0047] (1) The preparation method of component A: According to the weight parts of the raw materials described in Example 1 in Table 1, first mix part of the solvent and anti-settling agent, and then stir at a constant speed for 10 minutes at 1500r / min; then add bisphenol F type Epoxy resin and dispersant, at 1500r / min, stir at a constant speed for 10min; finally add coloring pigments, fillers, anti-rust pigments and mix, at 1500r / min, stir at a constant speed for 10min, and then use a horizontal sand mill to grind into a slurry material, and then add hydroxymethyl bisphenol A epoxy resin, special liquid resin, leveling agent and the remaining solvent to the slurry for reconciliation, stir at a constant speed for 20 minutes at 1500r / min, filter, and obtain A component;

[0048] (2) The preparation method of component B: according to the parts by weight of the raw materials described in Example 1 of Table 1, first add the modified polyamide curing agent, modified aliphatic Manni...

Embodiment 2

[0051] (1) The preparation method of component A: According to the weight parts of the raw materials described in Example 1 in Table 1, first mix part of the solvent and anti-settling agent, and then stir at a constant speed for 15 minutes at 1300r / min; then add bisphenol F type Epoxy resin and dispersant, at 1300r / min, stir at a constant speed for 15min; finally add coloring pigments, fillers, anti-rust pigments and mix, at 1300r / min, stir at a constant speed for 15min, and then use a horizontal sand mill to grind into a slurry material, and then add hydroxymethyl bisphenol A epoxy resin, special liquid resin, leveling agent and the remaining solvent to the slurry for reconciliation, stir at a constant speed of 1300r / min for 30min, filter to obtain component A;

[0052] (2) The preparation method of component B: according to the parts by weight of the raw materials described in Example 1 of Table 1, first add the modified polyamide curing agent, modified aliphatic Mannich base...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap