A kind of copper foil additive for the fifth generation mobile communication board, copper foil and its production process

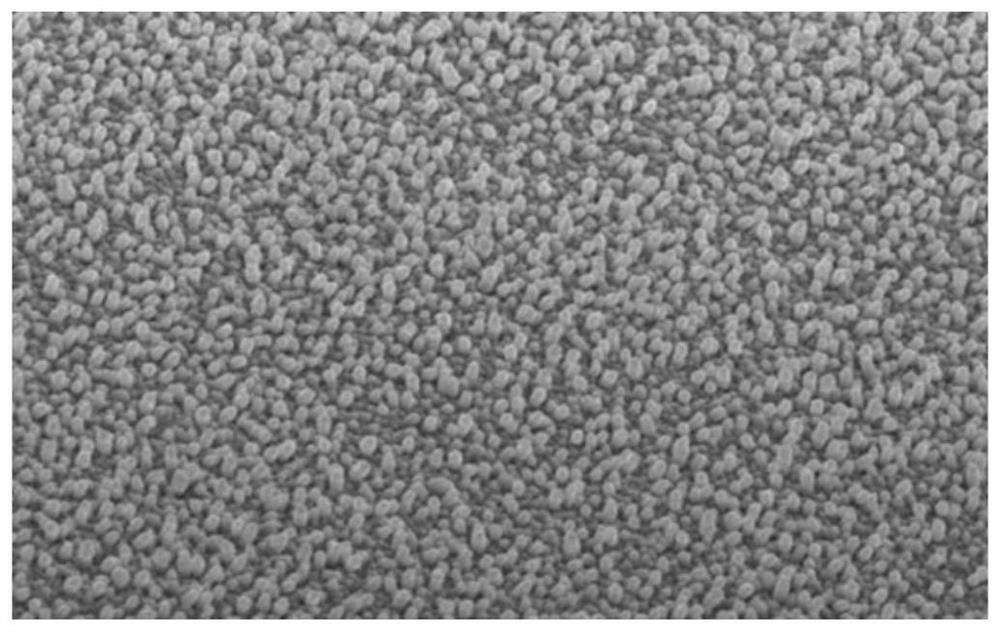

A mobile communication and additive technology, applied in electroforming, electrolysis process, etc., can solve the problems of unsatisfactory bonding force and signal loss, unsuitable copper foil, low roughness, etc., to improve the uniformity of microstructure and signal loss. less, the effect of reducing the roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

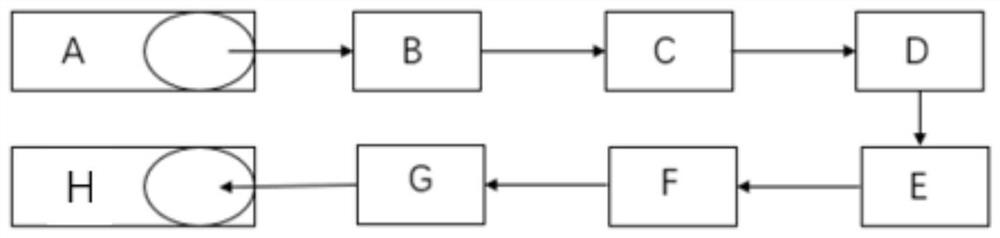

Method used

Image

Examples

Embodiment 1

[0058] An electrolytic copper foil additive for the fifth-generation mobile communication high-frequency and high-speed board, the additives are additive A and additive B;

[0059] Additive A includes the following components: 0.1 g / L of cerium sulfate and 1 g / L of sodium mercaptoimidazole propanesulfonate.

[0060] Additive B includes the following components: sodium phenyl dithiopropane sulfonate (BSP) 15 mg / L and thiazolinyl sodium dithiopropane sulfonate (SH110) 5 mg / L.

[0061] The preparation method of 12 μm copper foil comprises the steps:

[0062] (1) Preparation of electrolyte: adding copper to a solution containing sulfuric acid to obtain an electrolyte, the content of copper in the electrolyte is 60g / L, the content of sulfuric acid is 100g / L, and the temperature is 50°C;

[0063] (2) Preparation of raw foil: add additive A to the electrolyte prepared in step (1), and conduct electrodeposition on the cathode roll. During the electrodeposition process, the flow rate ...

Embodiment 2

[0069] An electrolytic copper foil additive for the fifth-generation mobile communication high-frequency and high-speed board, the additives are additive A and additive B;

[0070] Additive A includes the following components: lanthanum sulfate 0.2g / L and hexylbenzylamine salt 2g / L.

[0071] Additive B includes the following components: sodium phenyldithiopropanesulfonate (BSP) 20mg / L and sodium thiazolinyldithiopropanesulfonate (SH110) 7mg / L.

[0072] The preparation method of 18 μm copper foil comprises the steps:

[0073] (1) Preparation of electrolyte: adding copper to a solution containing sulfuric acid to obtain an electrolyte, the content of copper in the electrolyte is 65g / L, the content of sulfuric acid is 120g / L, and the temperature is 52°C;

[0074] (2) Preparation of raw foil: add additive A to the electrolyte prepared in step (1), and conduct electrodeposition on the cathode roller. The flow rate of the electrolyte during the electrodeposition process is 45m 3 / ...

Embodiment 3

[0079] An electrolytic copper foil additive for the fifth-generation mobile communication high-frequency and high-speed board, the additives are additive A and additive B;

[0080] Additive A includes the following components: 0.1 g / L of cerium sulfate, 0.1 g / L of lanthanum sulfate, 1 g / L of sodium mercaptoimidazole propanesulfonate and 1 g / L of hexylbenzylamine salt.

[0081] Additive B includes the following components: sodium phenyl dithiopropane sulfonate (BSP) 30 mg / L and thiazolinyl sodium dithiopropane sulfonate (SH110) 10 mg / L.

[0082] The preparation method of 35 μm copper foil comprises the steps:

[0083] (1) Preparation of electrolyte: adding copper to a solution containing sulfuric acid to obtain an electrolyte, the content of copper in the electrolyte is 70g / L, the content of sulfuric acid is 140g / L, and the temperature is 52°C;

[0084] (2) Preparation of raw foil: add additive A to the electrolyte prepared in step (1), and conduct electrodeposition on the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com