Environment-friendly energy-saving heat preservation building wall

A technology for building walls, environmental protection and energy saving, applied in buildings, protected buildings/shelters, building components, etc., can solve the problems of poor heat insulation and moisture resistance, complicated construction, etc., achieve remarkable purification and heat preservation effects, and simple construction , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

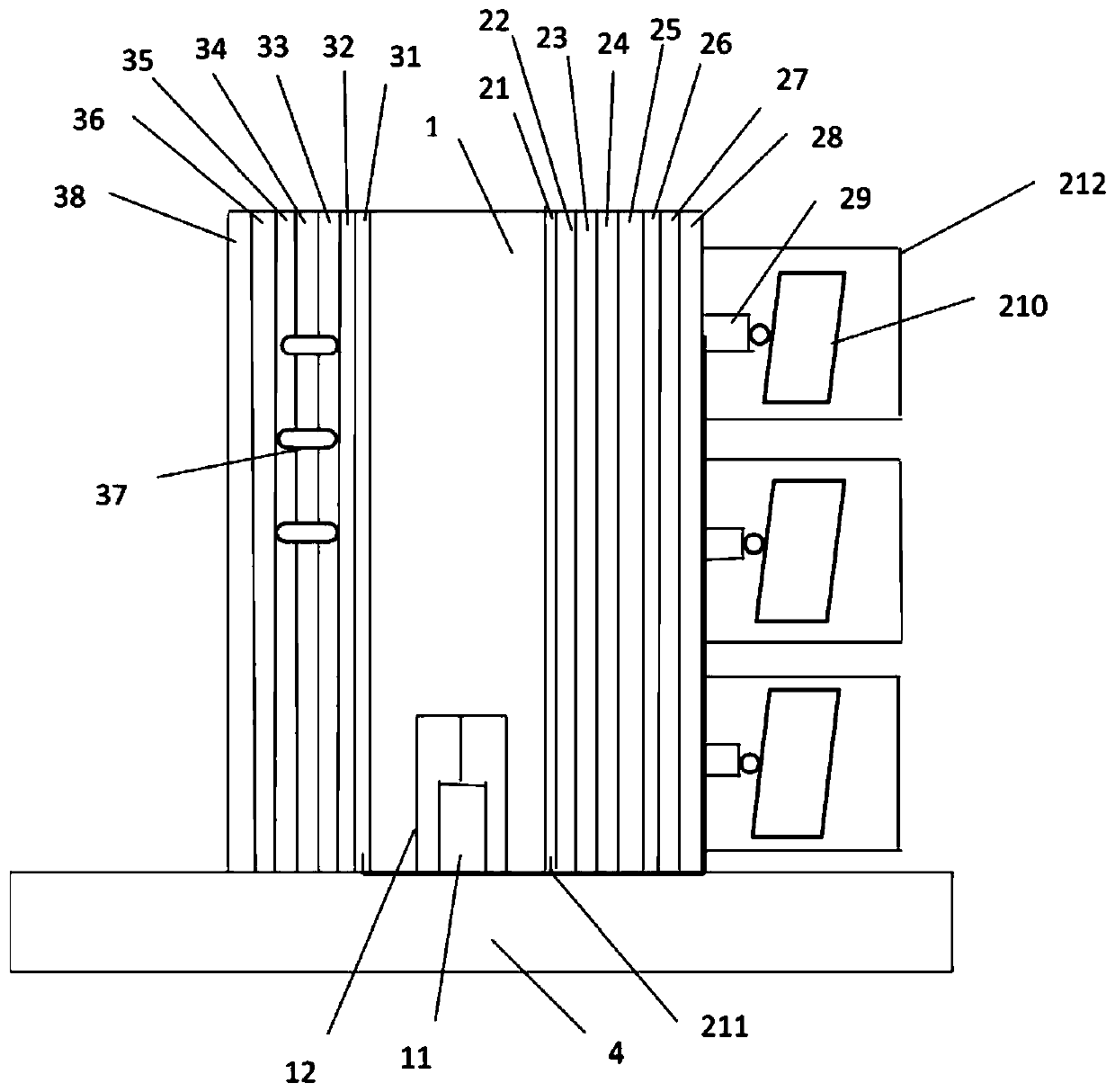

[0041] like figure 1 As shown, an environment-friendly, energy-saving and heat-preserving building wall includes three parts: a main wall 1 fixedly installed on a foundation 4, an outer wall and an inner wall, wherein the main wall 1 is composed of straw fiber concrete blocks, and the blocks Use strong mortar to bond between the blocks to ensure that the blocks are tightly bonded and better play the role of thermal insulation;

[0042] The anti-seismic damper 11 installed at the bottom of the main wall 1 is used to reduce the damage to the main wall 1 caused by earthquake disasters, and the anti-seismic protection layer 12 is used to ensure the normal use of the anti-seismic damper 11;

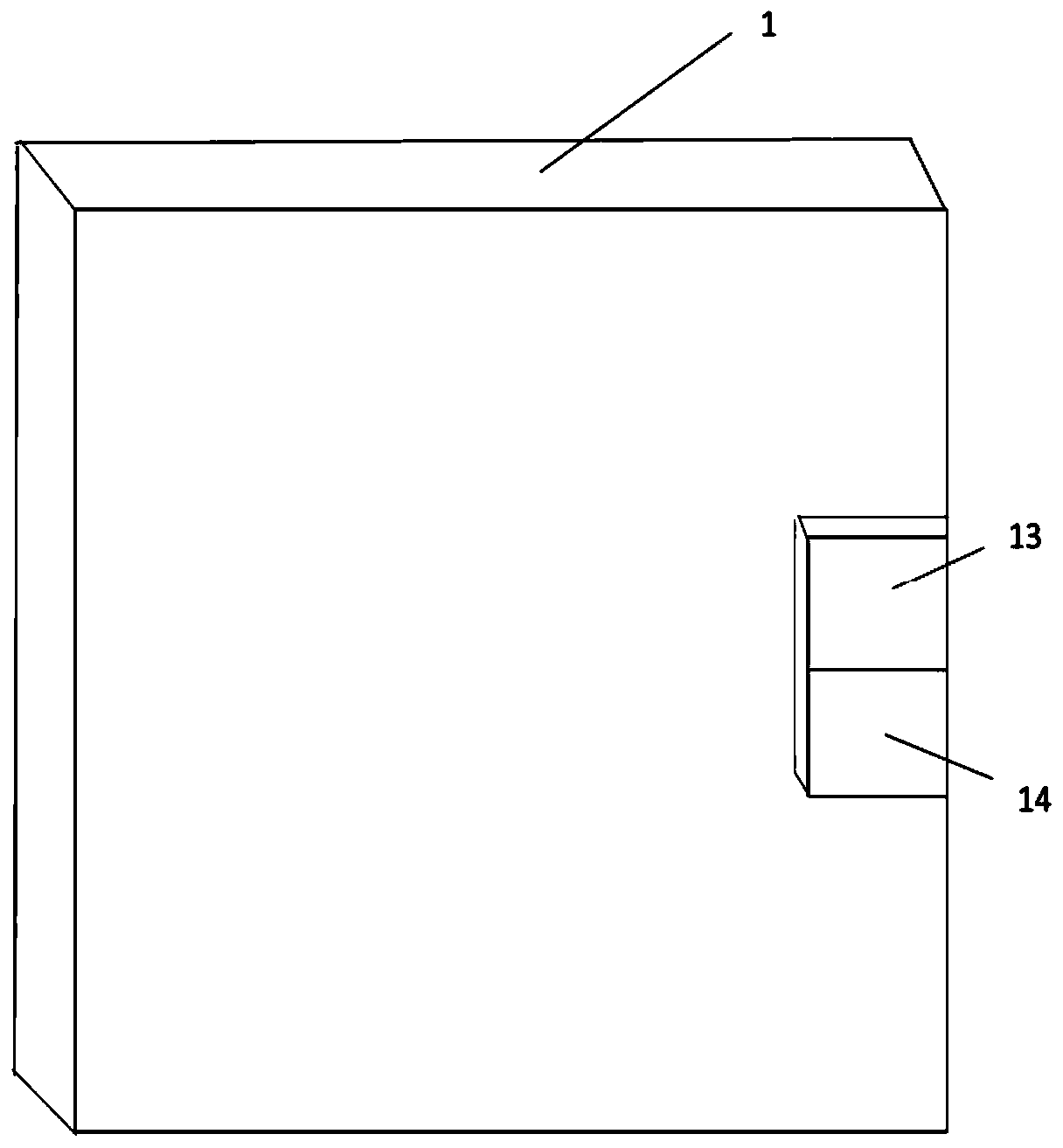

[0043] like figure 2 As shown, a temperature indicator 13 and a humidity indicator 14 are also installed on the outside of the main wall 1, which are used to detect the humidity and temperature changes of the wall, which helps the user to understand and improve the indoor air quality and qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com