Low-level deaerator system

A deaerator, low-level technology, applied in the direction of feed water heaters, chemical instruments and methods, preheating, etc., can solve the need for increased boiler feed water pump flow, can not prevent pump cavitation, instability, and sometimes no and other problems to achieve the effect of eliminating the possibility of cavitation, eliminating the possibility of vaporization, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

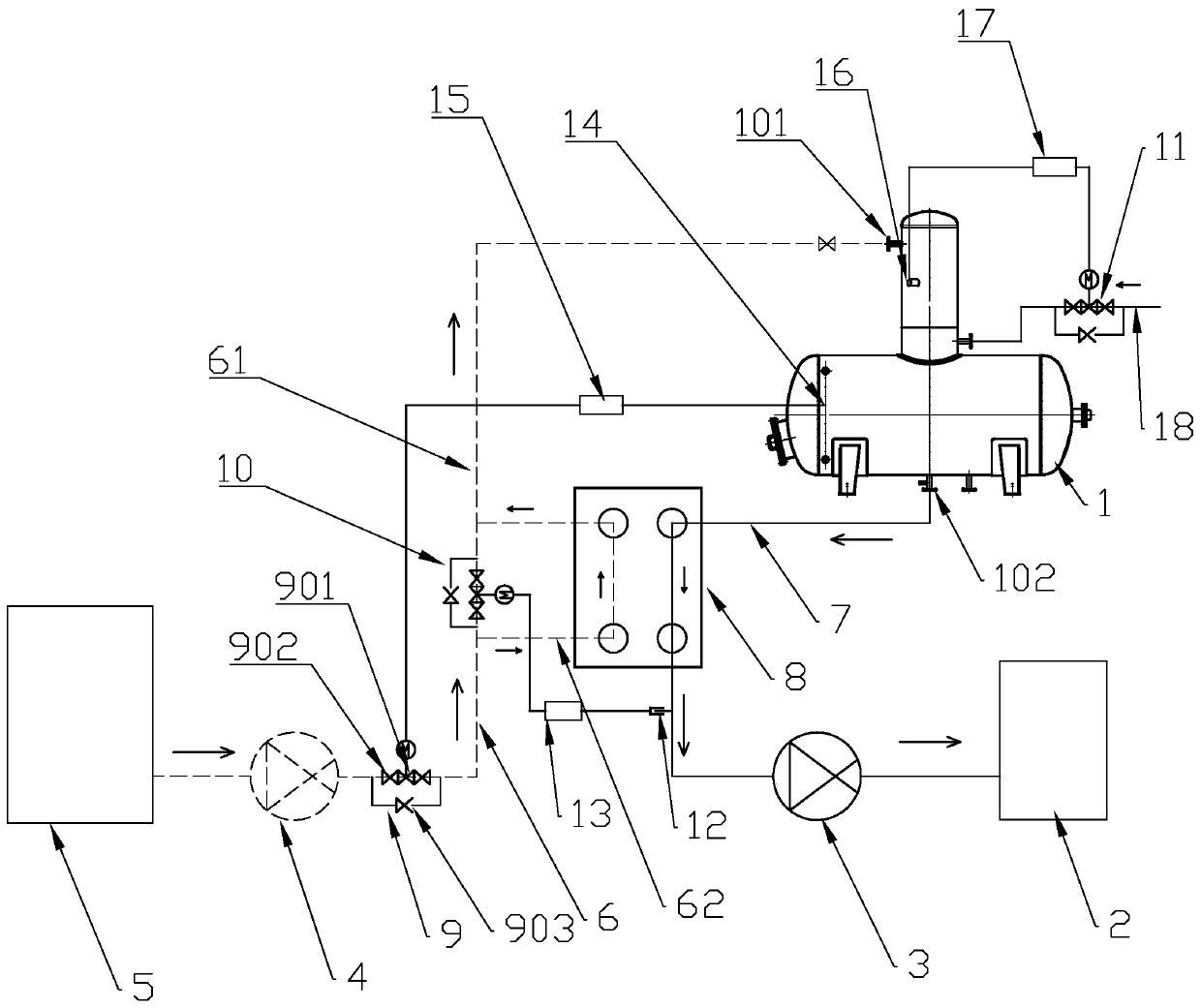

[0016] Refer to the attached figure 1 A low-level deaerator system of the present invention is described in detail below.

[0017] A low-level deaerator system of the present invention has a structure comprising a deaerator 1, a boiler 2, a boiler feed water pump 3, a deaerator water pump 4, and a water tank 5, and the water inlet 101 of the deaerator 1 passes through the deaerator water pump 4 and the water tank 5 connected, the deaerator water pump 4 and the water inlet 101 of the deaerator 1 are the deaerator water inlet pipeline 6, the water outlet 102 of the deaerator 1 is connected with the boiler 2 through the boiler feed water pump 3, the deaerator 1 Between the water outlet 102 and the boiler feed water pump 3 is the deaerator outlet pipeline 7, and a plate heat exchanger 8 is arranged between the deaerator inlet pipeline 6 and the deaerator outlet pipeline 7, and the deaerator inlet pipeline 6 is divided into two paths, including a first water inlet pipeline 61 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com