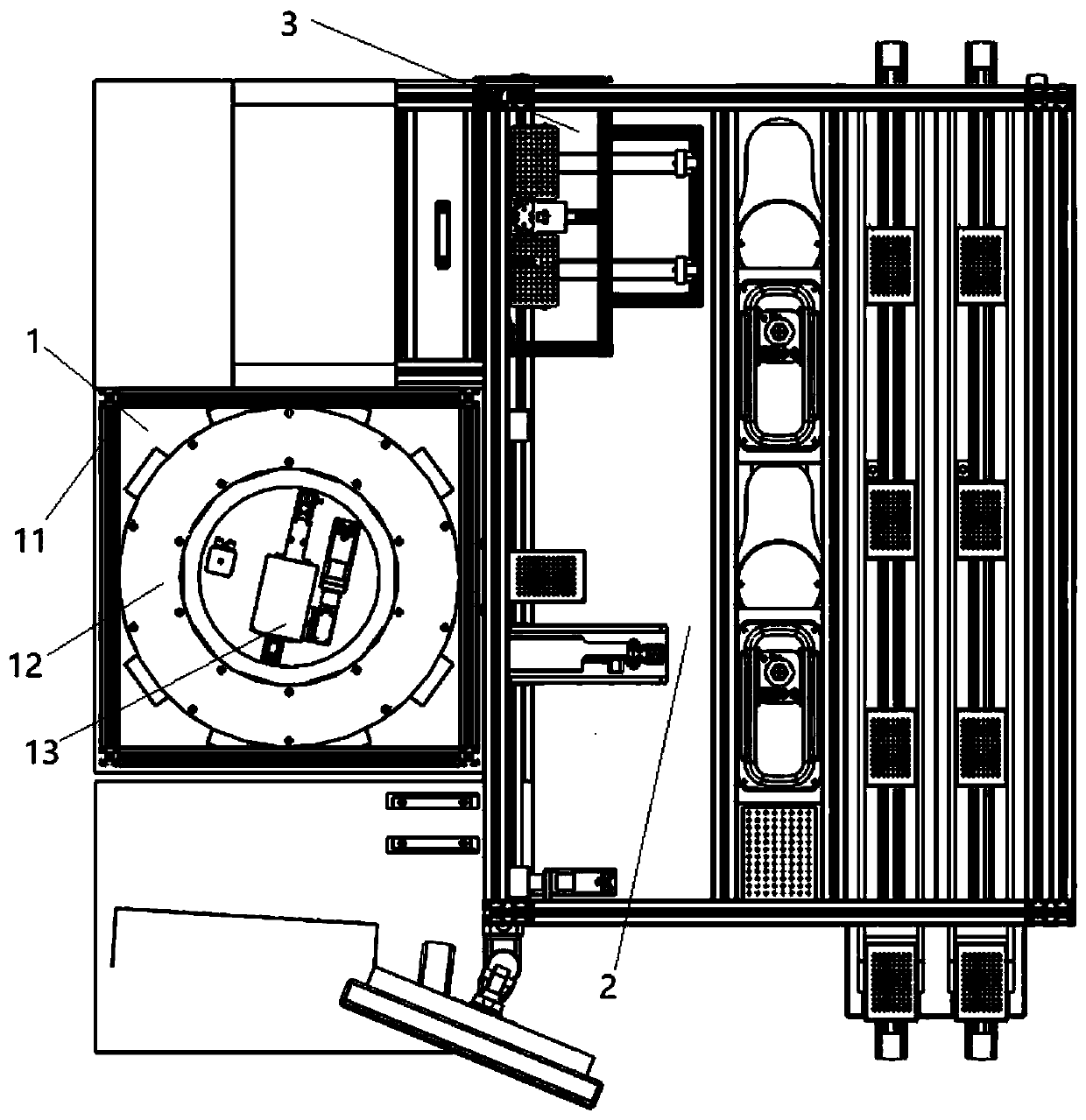

Automatic pipetting system and control method thereof

A liquid pipetting and automatic technology, applied in the field of life science, to achieve the effect of comprehensive functions, lower prices, and improved international competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

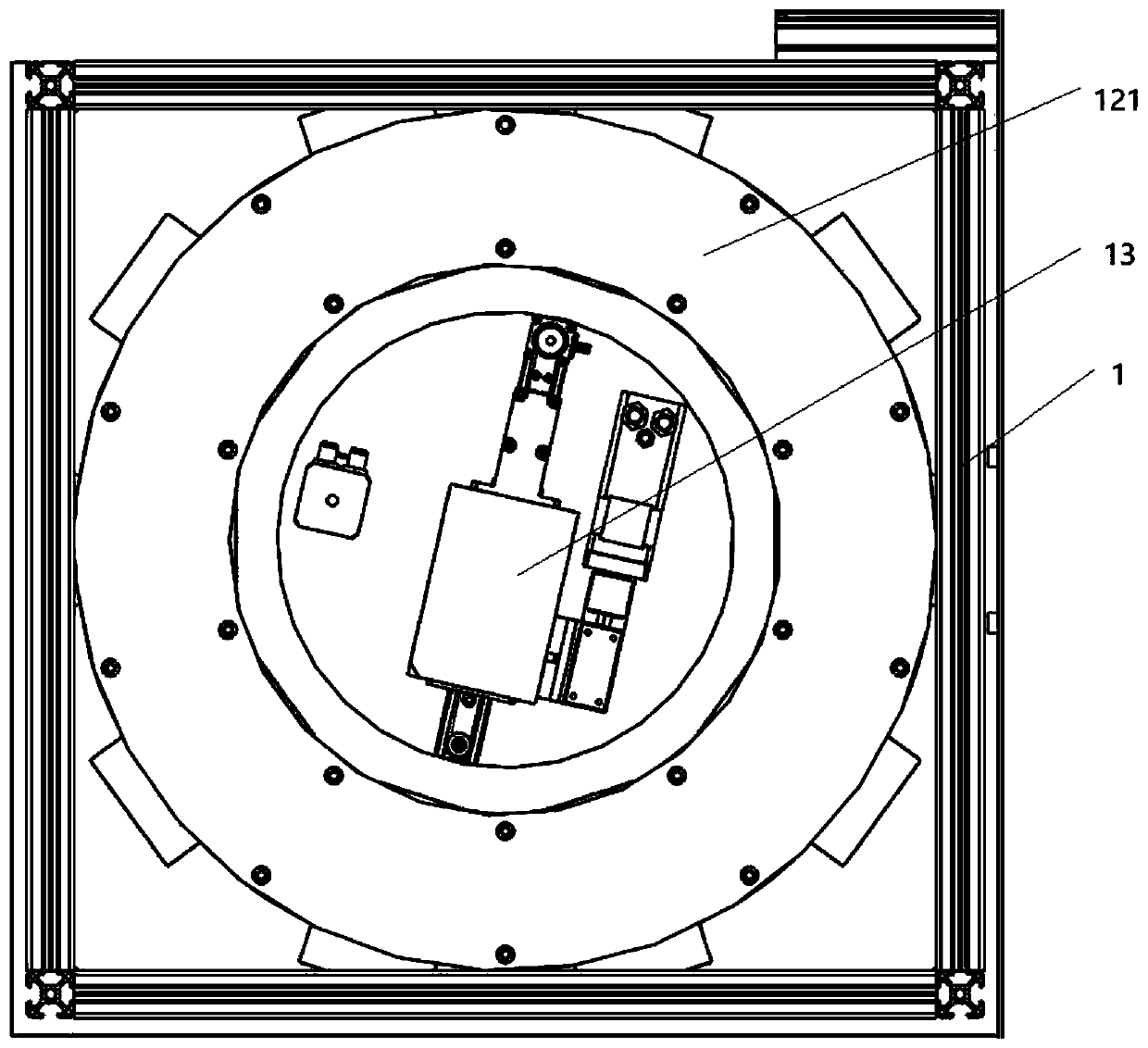

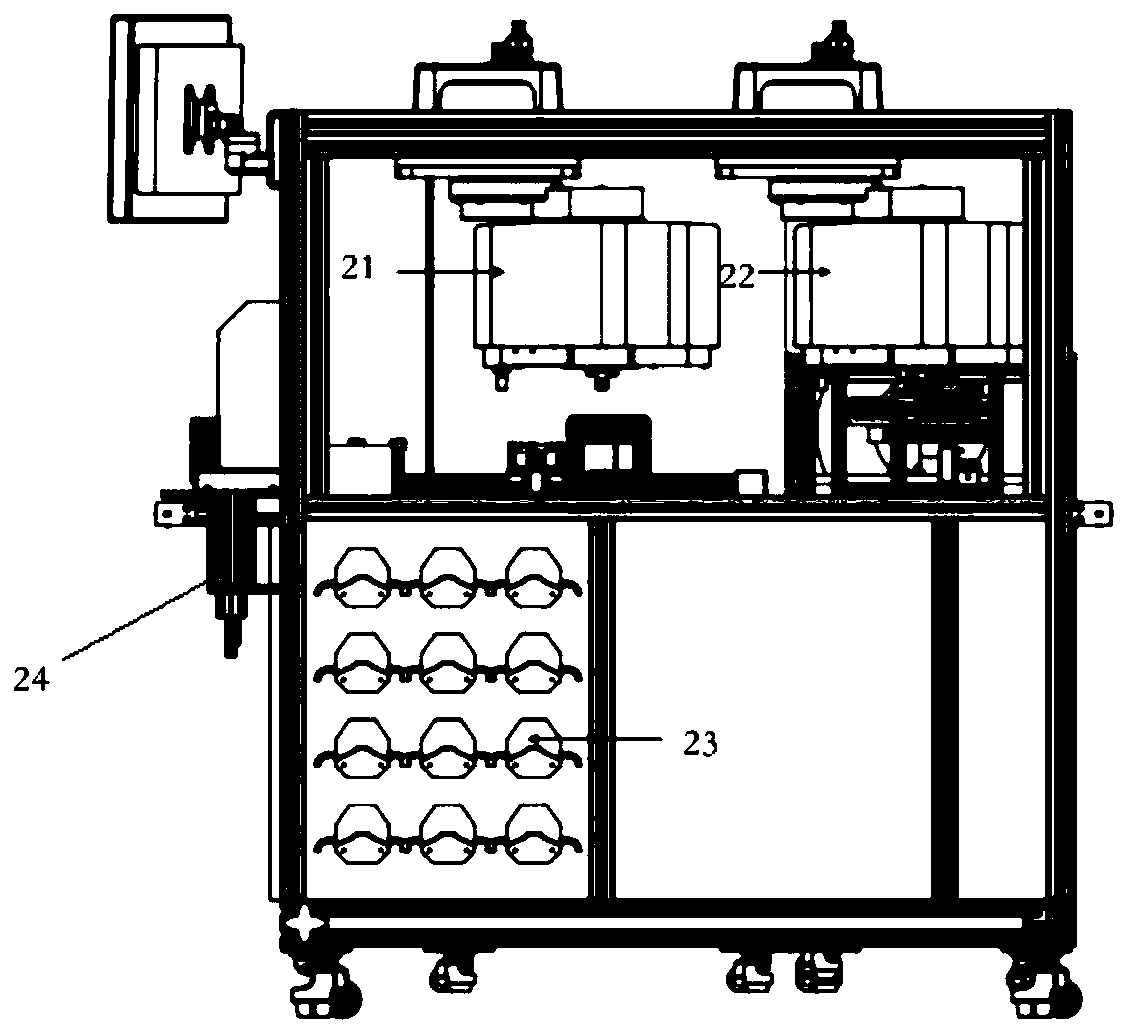

Examples

specific Embodiment approach

[0106] As a specific implementation, step S4 includes:

[0107] S41. Control the transfer assembly to perform a translational movement in a direction perpendicular to the gap member to a first predetermined position, and make each protrusion matching the inner diameter of the wide end of the gun head be opposite to each gun head on the gap member;

[0108]S42. Control the convex head to move down the first predetermined distance to the second predetermined position, so that each convex head can be inserted into the gun head; the first predetermined distance is from the original position (that is, the initial position) of the convex head to the loading and unloading gun tip distance;

[0109] S43. The control protrusion moves upward to the original position, and then the transfer assembly performs a translational movement in a direction perpendicular to the gap member to a second predetermined position.

[0110] Optionally, step S5 includes:

[0111] S51. Adjust the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com