Multi-closed-loop temperature and humidity control system for mechanically testing micro-cavity environment

A temperature and humidity control, multi-closed-loop technology, applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem that the temperature and humidity generator cannot accurately control temperature and humidity, and achieve signal feedback speed Fast, dual control, high internal integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

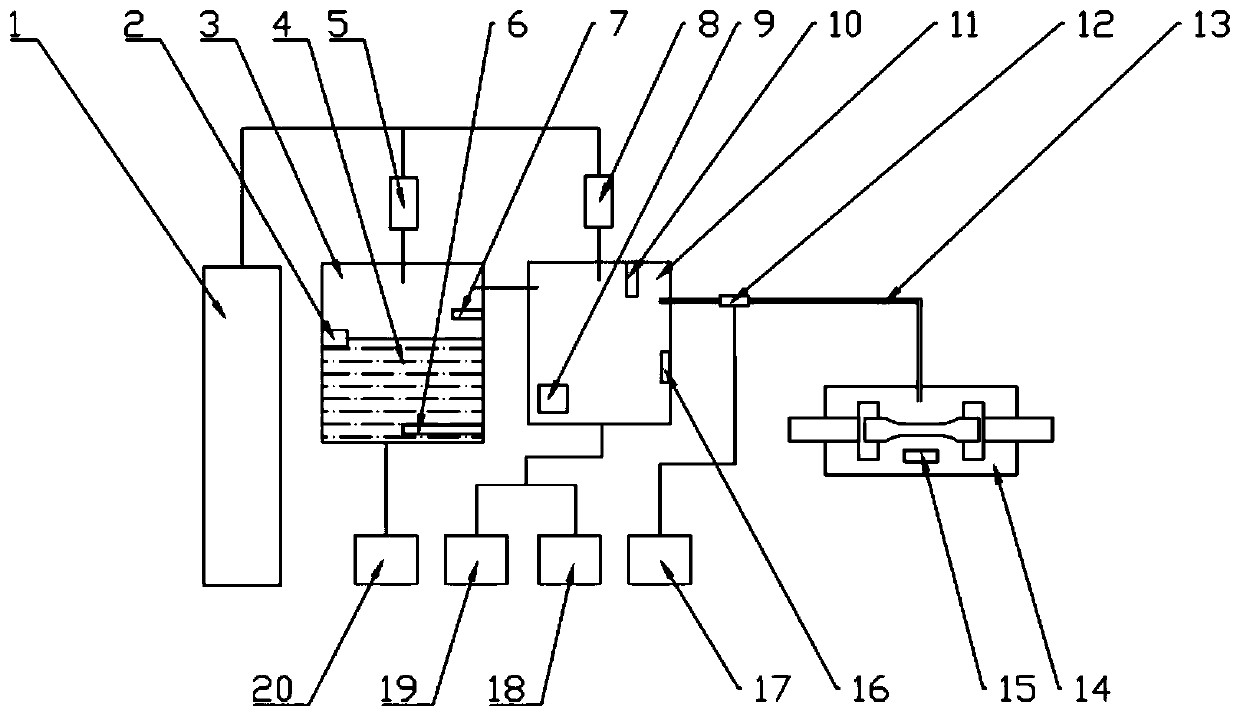

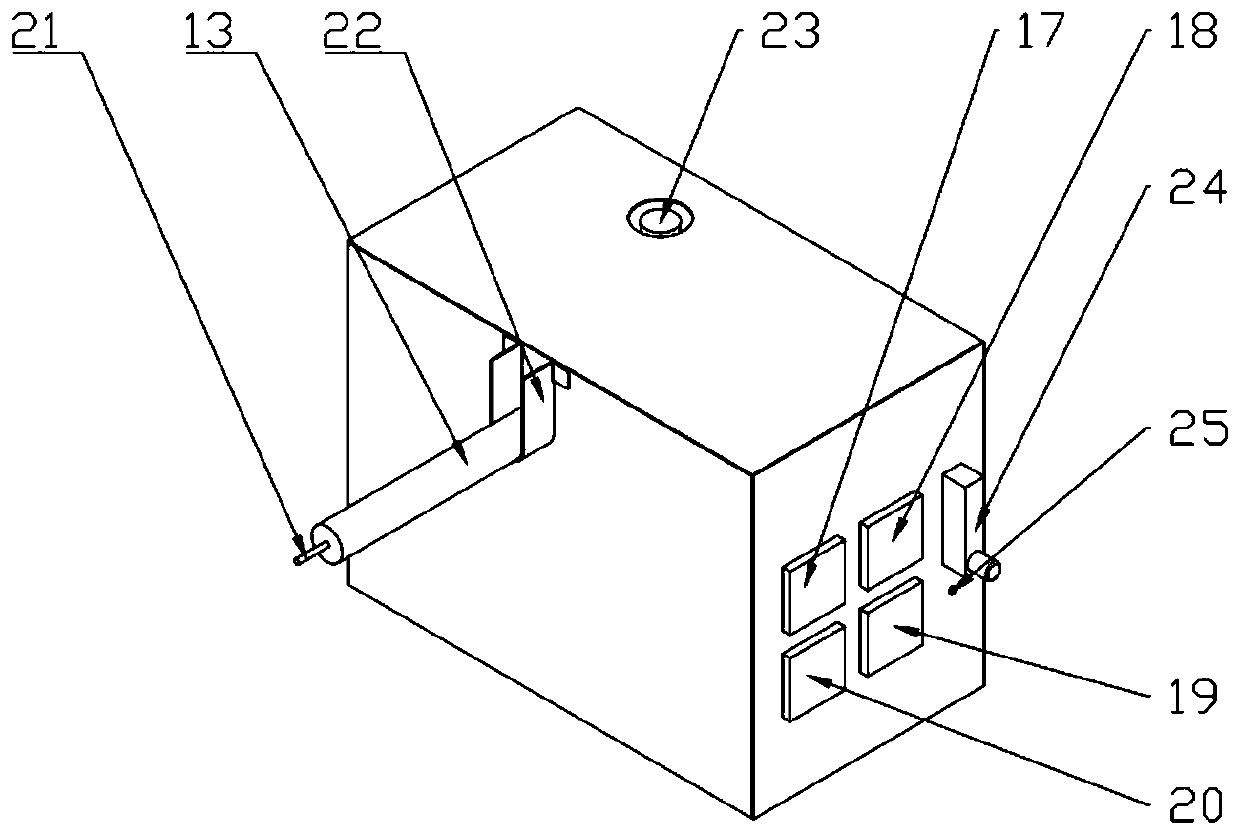

[0024] like figure 1 As shown, this embodiment provides a multi-closed-loop temperature and humidity control system for mechanical testing of micro-cavity environments. Composed of control device and power supply device.

[0025] The gas source device adopts a high-purity nitrogen cylinder 1, which is used to transport the dry gas from the outside to the humidification box 3 and the gas storage box 11, and the air pressure is controlled by the inlet valve 24.

[0026] The humidifying device includes a humidifying box 3 , a first gas mass flow meter 5 , a water level sensor 2 , a heating pipe 6 and a first temperature sensor 7 . The humidification box 3 is connected to the nitrogen cylinder 1 through a gas pipe. The first gas mass flowmeter 5 adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com