Power transmission line wire defect detection method based on machine vision

A power transmission line, machine vision technology, applied in the direction of neural learning methods, optical testing flaws/defects, instruments, etc., can solve the problem of shooting angles and scenes that are difficult to be universal, wires do not have segmentation and detection capabilities, and transmission lines operate normally Hidden dangers and other problems, to achieve the effect of state identification and defect location, improve practical performance, and reduce processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with specific examples.

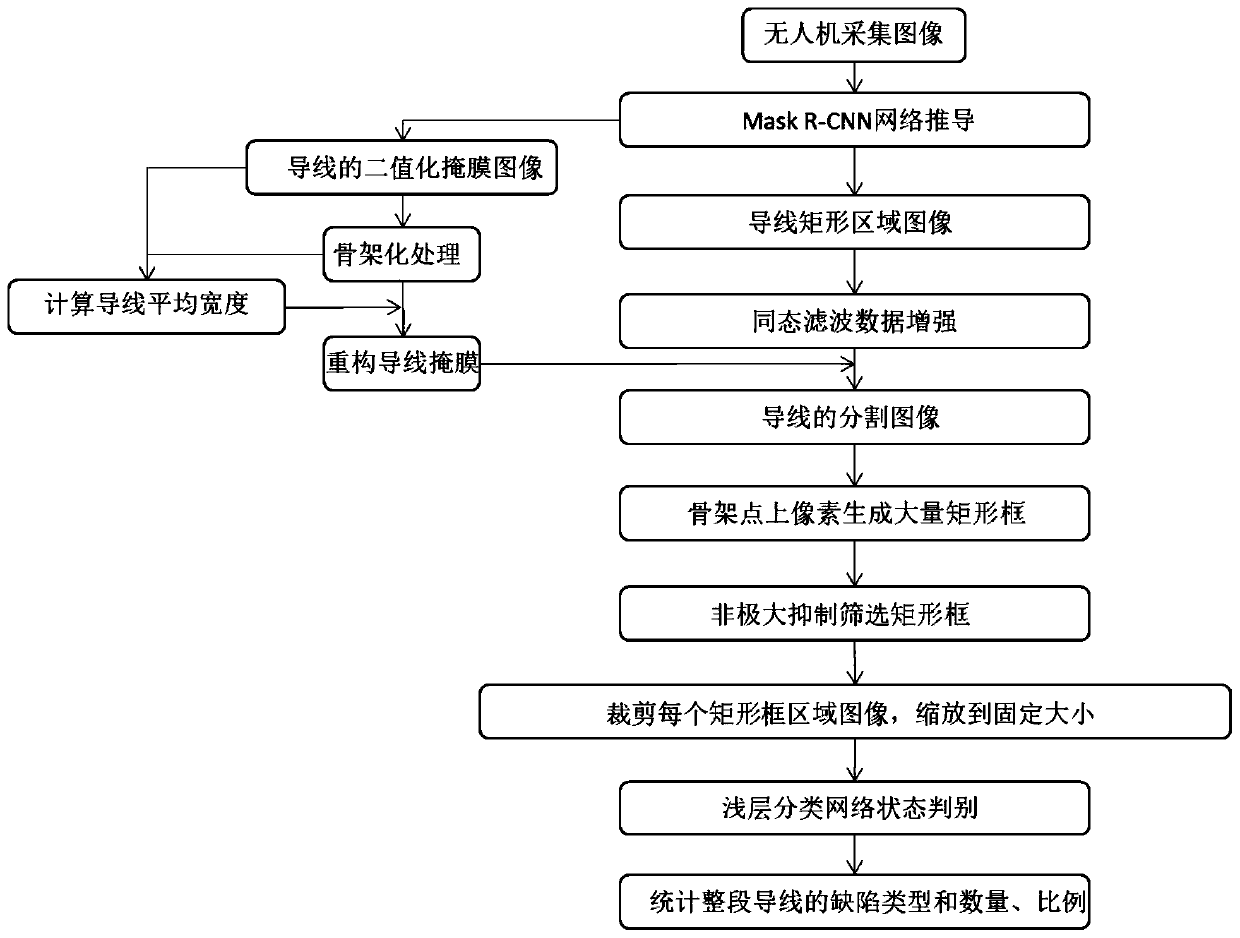

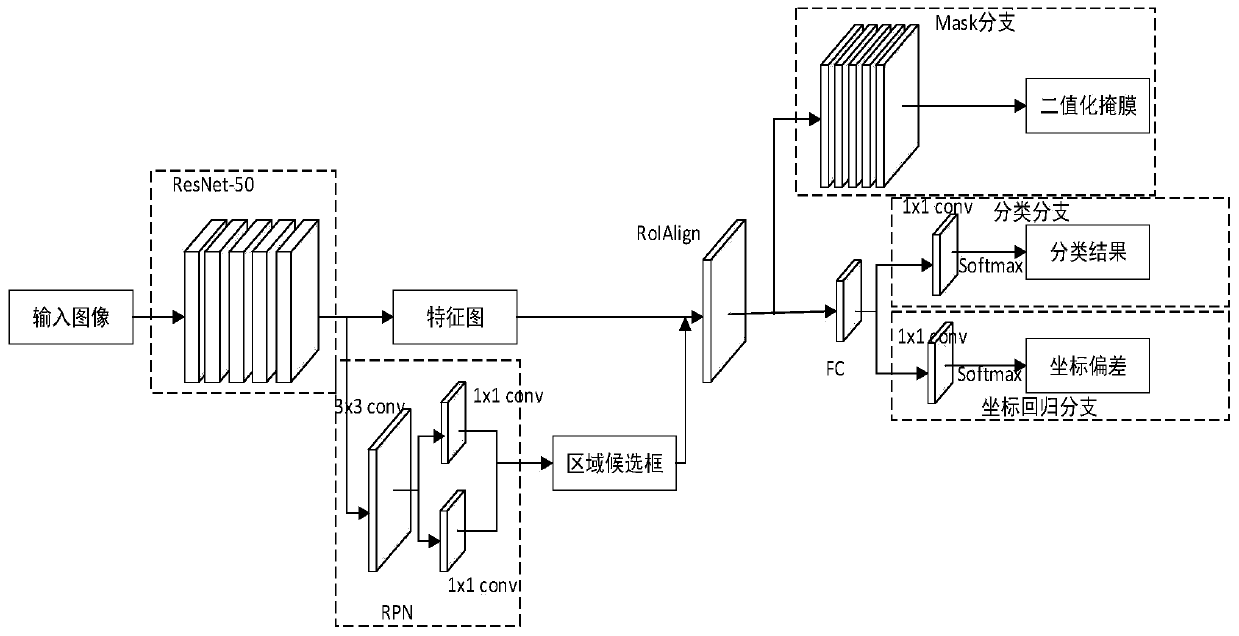

[0054] Such as figure 1 As shown, the specific conditions of the machine vision-based transmission line conductor defect detection method provided in this embodiment are as follows:

[0055] Step 1: The UAV conducts fixed line inspections on the transmission line, and takes on-site images of high-voltage towers near the towers, such as figure 2 shown, and transmitted to the remote server over a long distance through the 4G network.

[0056] Step 2: Divide the on-site images collected by the drone into the training data set and the test data set in a ratio of 7:3, use Labelme software to mark the edges of the wires in the training data set, and obtain the label file of the corresponding image in json format , the annotation file includes the rectangular coordinate data of the wire target in the image, the mask point set data and category information, and the pictures and lab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com