Photovoltaic-photothermal all-in-one machine

An all-in-one, photovoltaic technology, applied in photovoltaic thermoelectric hybrid power generation, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of high solar energy loss, low photoelectric conversion efficiency, and inability to install at the same time, to overcome the low frequency of use and overcome conversion Low efficiency, avoiding the effect of thickness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

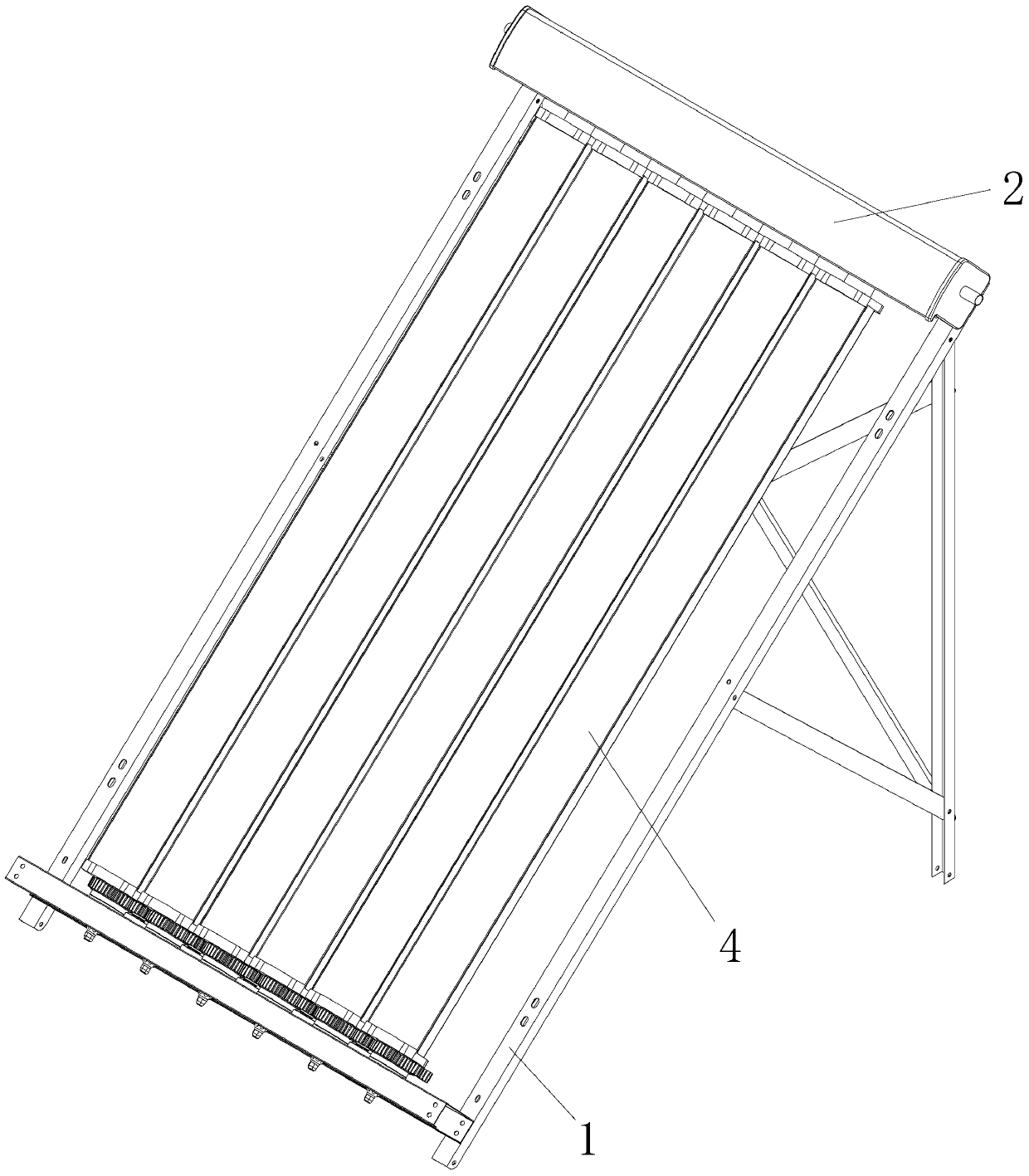

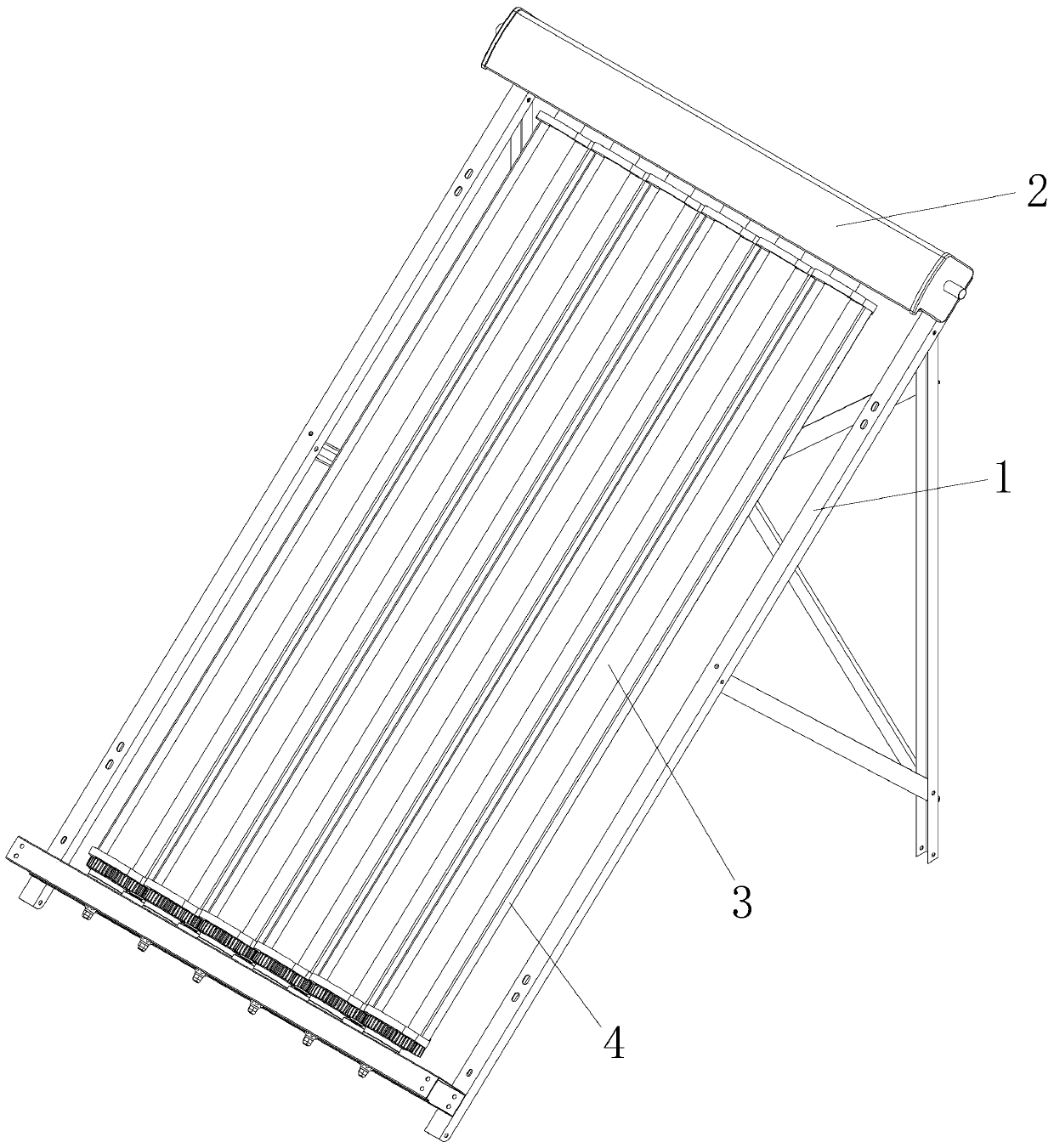

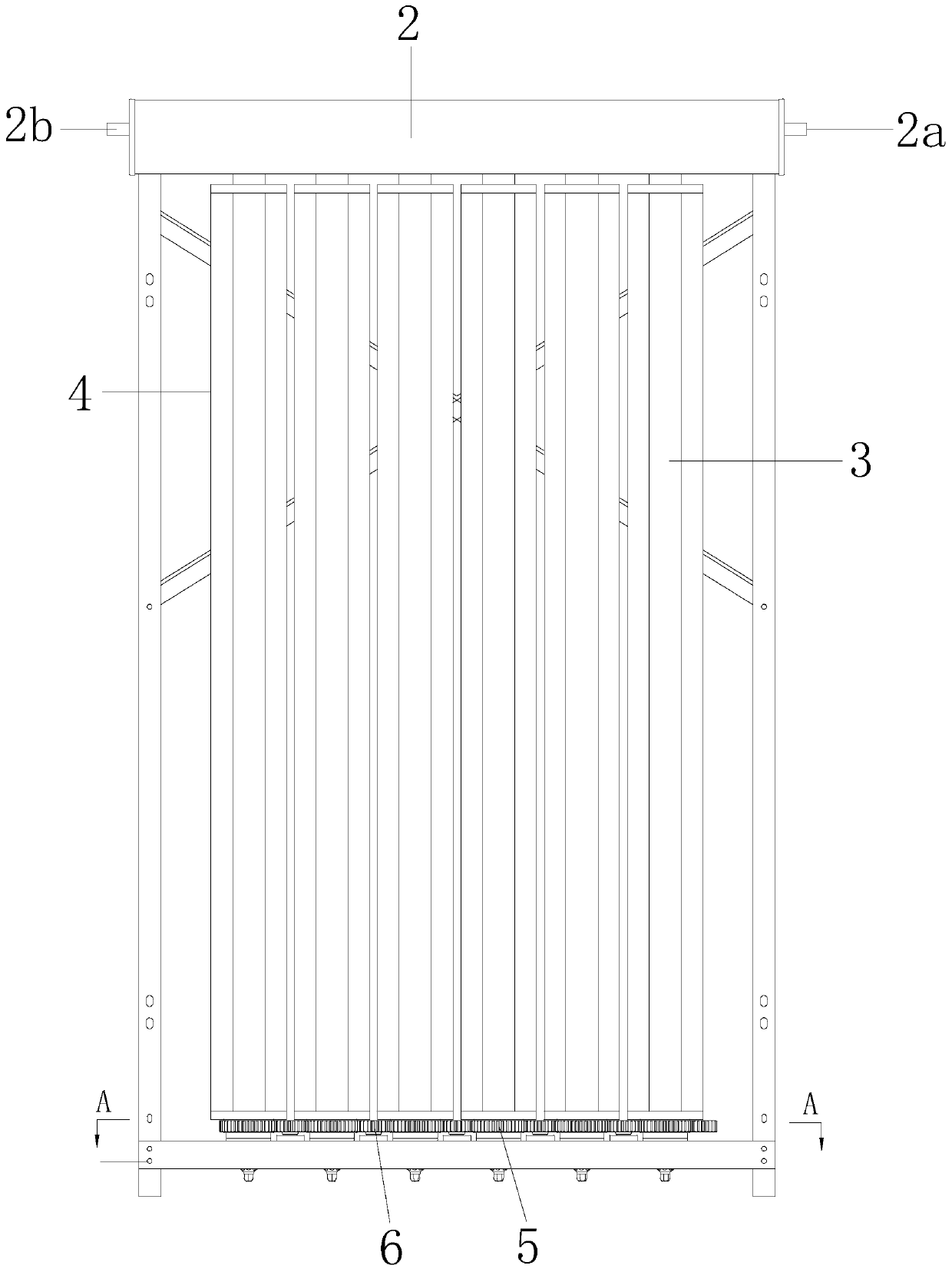

Embodiment 1

[0068] Figure 1 to Figure 5 A preferred embodiment of the photovoltaic-photothermal integrated machine of the present application is shown. Same as some existing photothermal devices (such as solar water heaters), the photovoltaic-photothermal integrated machine of this embodiment also includes a base frame 1 on which a water tank 2 and six heat collecting tubes 3 are fixedly arranged. The water tank 2 has a water inlet port 2a and a water outlet port 2b. In actual application, the water inlet port 2a and the water outlet port 2b are respectively connected to the water inlet pipeline and the water outlet pipeline, so as to feed flowing water into the water tank 2. One end of each aforementioned heat collecting tube 3 is all inserted in the water running chamber (the joint is sealed and watertight). For the convenience of manufacture and assembly, the aforementioned heat collecting tubes 3 are arranged in the same plane at equal intervals. The base frame 1 is used as the sup...

Embodiment 2

[0090] Image 6 with Figure 7 It shows the second preferred embodiment of the photovoltaic-photothermal integrated machine of the present application. The structure of the photovoltaic-photothermal integrated machine in this embodiment is basically the same as that of Embodiment 1, the only difference is that the heat collecting tube 3 pivots The connection (not the fastening connection in the first embodiment) is on the base frame 1 , and the photovoltaic panel 4 and the heat collecting tube 3 in the same photovoltaic-photothermal unit are fixedly connected to each other through the connecting frame 9 . When the photovoltaic panel 4 rotates on the base frame 1 , the heat collecting tube 3 fixed with the photovoltaic panel 4 also rotates accordingly. Naturally, when the heat collecting tube 3 pivots on the base frame 1 , the photovoltaic panel 4 fixed to the heat collecting tube 3 also rotates with the heat collecting tube 3 .

[0091] The pivotal connection structure betwe...

Embodiment 3

[0101] Figure 8 It shows the third preferred embodiment of the photovoltaic-photothermal integrated machine of the present application. The structure of the photovoltaic-photothermal integrated machine of this embodiment is basically the same as that of the first embodiment. The only difference is that this embodiment is in A reflective plate 8 is fixedly connected to the side of the photovoltaic panel 4 facing the heat collecting tube 3 , and the reflective plate 8 has a reflective surface facing the heat collecting tube 3 .

[0102] When the photovoltaic-photothermal integrated machine is in the photothermal working mode, both the photovoltaic panel 4 and the reflector 8 fixed on the photovoltaic panel are turned to the backlight side of the heat collecting tube 3, and the reflective surface of the reflector 8 faces the sunlight at this time, from The sunlight incident on the side of the heat collecting tube 3 will shoot to the reflective surface of the reflector 8, and aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com