Steel slag-based multi-metal composite phosphate cement

A composite phosphate and multimetal technology, applied in the field of steel slag-based multimetal composite phosphate cement, can solve the problems of ineffective utilization of steel slag, potential safety hazards, immature technology, etc., to improve the solidification speed and improve the operability sex, and the effect of expanding application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

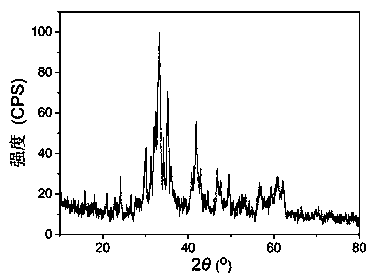

[0018] (1) The slag-based multi-metal composite phosphate cement of Benxi Steel is composed of 100g of steel slag, 16g of ammonium dihydrogen phosphate, and 1g of borax; the steel slag is ground and passed through a 120-mesh sieve, and the sieve residue is less than 5%. The XRD diagram of the steel slag is shown in figure 1 ;

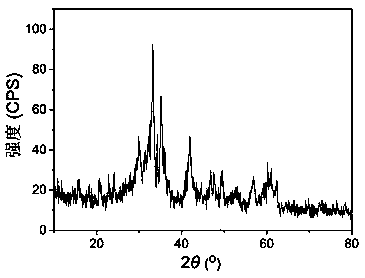

[0019] (2) Weigh the mixed material in step (1), add 23.4g of water, mix and stir for 3 minutes, quickly pour it into a 20mm×20mm×20mm six-unit mold, and vibrate on a vibration table to form a steel slag-based multi-metal composite Phosphate cement sample; the sample was demolded after 3 hours of molding, and its compressive strength was tested by natural curing to a certain age; the compressive strength of the sample 1d was 21.8MPa; XRD phase analysis was carried out on the material, and the results are shown in figure 2 , It can be seen from the figure that the material contains calcium-silicon solid solution and RO phase.

Embodiment 2

[0021] (1) The slag-based multi-metal composite phosphate cement of Benxi Steel is composed of 100g of steel slag, 25g of ammonium dihydrogen phosphate, and 2g of borax; the steel slag is ground and passed through a 120-mesh sieve, and the sieve residue is less than 5%;

[0022] (2) Weigh the mixed material in step (1), add 25.6g of water, mix and stir for 3 minutes, quickly pour it into a 20mm×20mm×20mm six-unit mold, and vibrate on a vibration table to form a steel slag-based multi-metal composite Phosphate cement sample; the sample was demolded after 3 hours of molding, and its compressive strength was tested by natural curing to a certain age; the compressive strength of the sample 1d was 20.4MPa.

Embodiment 3

[0024] (1) The slag-based multi-metal composite phosphate cement of Benxi Steel is composed of 100g of steel slag, 45g of ammonium dihydrogen phosphate, and 4g of borax; the steel slag is ground and passed through a 120-mesh sieve, and the sieve residue is less than 5%;

[0025] (2) Weigh the mixed material in step (1), add 30g of water, mix and stir for 3 minutes, quickly pour it into a 20mm×20mm×20mm six-unit mold, and vibrate on a vibrating table to form a steel slag-based multi-metal composite Phosphate cement sample; the sample was demolded after 3 hours of molding, and its compressive strength was tested by natural curing to a certain age; the compressive strength of the sample 1d was 20.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com