Non-slip slipper foaming material and preparation method thereof

A foamed material and slippers technology, applied in the field of shoe product processing, can solve the problems of small elongation at break, poor comprehensive use performance, and reduced tensile strength, and achieve the change of elongation at break, overcome cracking, The effect of high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

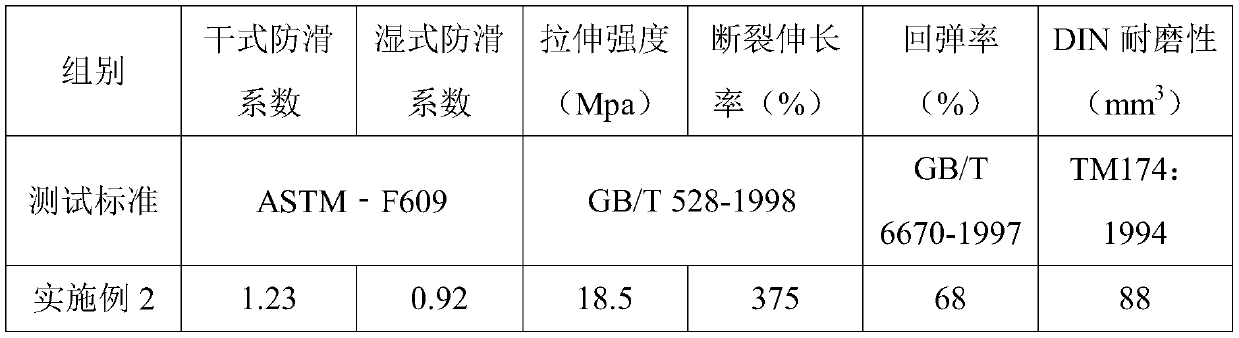

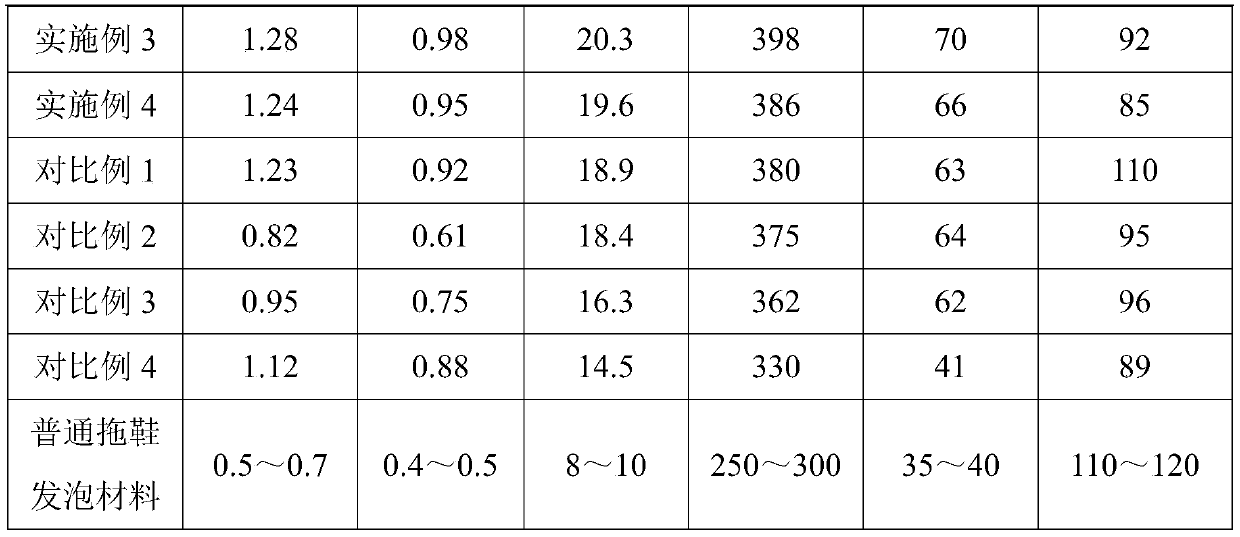

Examples

Embodiment 1

[0036] A foaming material for anti-slip slippers, comprising the following raw materials in parts by weight: 20-30 parts of natural rubber, 35-50 parts of styrene-butadiene rubber, 40-55 parts of butadiene rubber, 8-15 parts of high wear-resistant carbon black, polystyrene 6-8 parts of butylene elastomer, 5-12 parts of anti-slip agent, 5-10 parts of short fiber, 5-10 parts of zinc oxide, 0.7-5 parts of zinc stearate, 1-5 parts of stearic acid, crosslinking agent 1 to 4 parts, 2 to 10 parts of expansion agent and 0.5 to 5 parts of foaming agent.

[0037] In this embodiment, the crosslinking agent is selected from one or more mixtures of dicumyl peroxide, ethylene glycol dimethacrylate and trimethylolpropane trimethacrylate.

[0038] In this embodiment, the expansion agent is alunite or calcium oxide.

[0039] In this embodiment, the anti-slip agent is a mixture of epoxy resin, hydrogenated resin, and Kumho nitrile in a weight ratio of 3:1:5.

[0040] In this embodiment, the s...

Embodiment 2

[0050] A foaming material for anti-slip slippers, comprising the following raw materials in parts by weight: 20 parts of natural rubber, 35 parts of styrene-butadiene rubber, 45 parts of butadiene rubber, 8 parts of high wear-resistant carbon black, 8 parts of polybutene elastomer, anti-slip 5 parts of agent, 7 parts of short fiber, 5 parts of zinc oxide, 3.5 parts of zinc stearate, 2.5 parts of stearic acid, 2 parts of crosslinking agent, 4.5 parts of expansion agent and 2.5 parts of foaming agent.

[0051] In this embodiment, the crosslinking agent is a mixture of ethylene glycol dimethacrylate and trimethylolpropane trimethacrylate.

[0052] In this embodiment, the expansion agent is alunite.

[0053] In this embodiment, the anti-slip agent is a mixture of epoxy resin, hydrogenated resin, and Kumho nitrile in a weight ratio of 3:1:5.

[0054] In this embodiment, the short fibers are carbon-pentosan fiber copolymers.

[0055] In this embodiment, the foaming agent is AC foa...

Embodiment 3

[0064] A foaming material for anti-slip slippers, comprising the following raw materials in parts by weight: 25 parts of natural rubber, 40 parts of styrene-butadiene rubber, 45 parts of butadiene rubber, 10 parts of high wear-resistant carbon black, 6.5 parts of polybutene elastomer, anti-slip 8 parts of agent, 7.5 parts of short fiber, 8 parts of zinc oxide, 3.5 parts of zinc stearate, 2.5 parts of stearic acid, 3 parts of crosslinking agent, 5 parts of expansion agent and 4 parts of foaming agent.

[0065] In this embodiment, the crosslinking agent is dicumyl peroxide.

[0066] In this embodiment, the expansion agent is calcium oxide.

[0067] In this embodiment, the anti-slip agent is a mixture of epoxy resin, hydrogenated resin, and Kumho nitrile in a weight ratio of 3:1:5.

[0068] In this embodiment, the short fibers are carbon-pentosan fiber copolymers.

[0069] In this embodiment, the foaming agent is AC foaming agent.

[0070] In this embodiment, a method for prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com