Device for electrified crushing and electrolyte recovery of waste power lithium battery

A technology for electrolyte recycling and lithium batteries, applied in battery recycling, waste collector recycling, secondary batteries, etc., can solve the problems of difficult recycling technology and high recycling costs, and achieve the effects of abundant reserves, improved efficiency, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

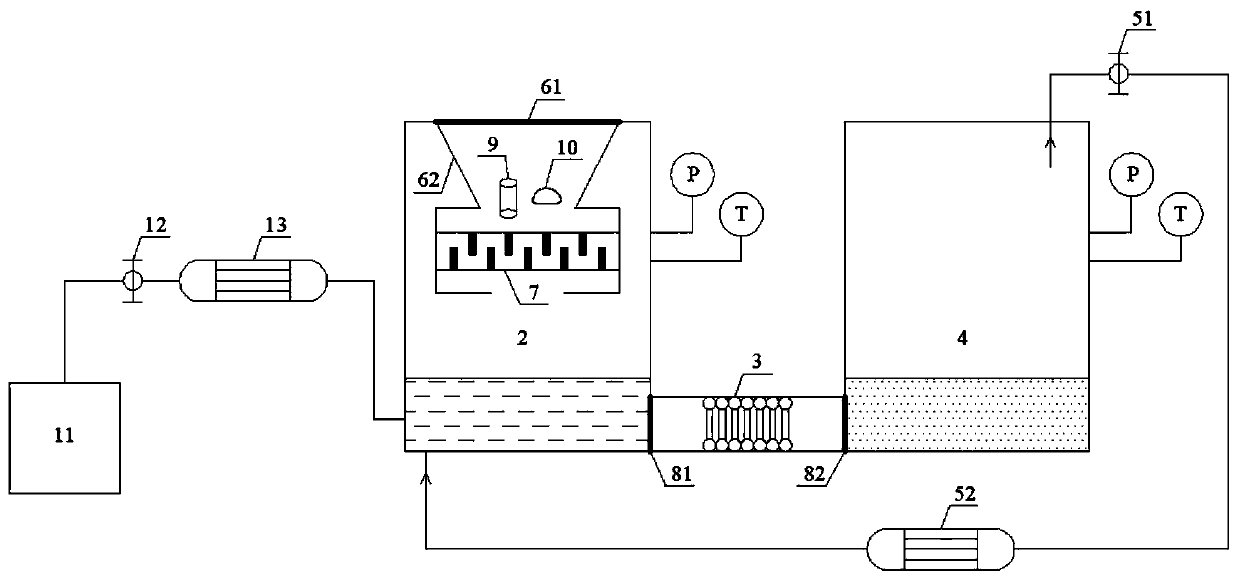

[0021] like figure 1 As shown, it is a preferred charging crushing and electrolyte recovery device for waste power lithium batteries of the present invention, including an air intake system, a fixed reaction kettle 2, a filter device, an electrolyte collection kettle 4 and a gas outlet system connected in sequence.

[0022] The intake system includes an inert gas source 11, an intake valve 12 and an intake machine 13. The inert gas provided by the inert gas source 11 enters the fixed reaction vessel through the intake valve 12 and the intake machine 13 for providing an inert atmosphere and adjusting The pressure inside the reactor was fixed.

[0023] The fixed reaction kettle 2 is a fully sealed device, and the inner wall is coated with fluorine-resistant materials to prevent electrolyte corrosion. The top of the fixed reaction kettle is provided with an inclined feeding hopper 62 with an inclination angle of 45°. A feed plate 61, when the waste power lithium battery 9 (as at...

example 1

[0031] combine figure 1 The device shown is used to carry out charged crushing of waste power lithium batteries and recovery of electrolyte. The specific process is as follows:

[0032] First, open the feed plate, and put the waste power LiCoO 2 The battery and dry ice are mixed into the feeding hopper at a mass ratio of 1:2. After the feeding is completed, the feeding plate is closed and the 1 # automatic shutter and 2 # Automatic baffle, open the outlet valve and air extractor, at this time, the fixed reaction kettle and the electrolyte collection kettle are fully sealed;

[0033]The inert gas source is argon, open the inlet valve and the inlet machine, and after a period of time, close the inlet machine, the air extractor, the inlet valve and the outlet valve and 1 # automatic shutter and 2 # Automatic baffle, at this time, the fixed reactor is filled with argon;

[0034] Turn on the roller shearing machine to start crushing. After crushing, adjust the temperature of t...

example 2

[0038] combine figure 1 The device shown is used to carry out charged crushing of waste power lithium batteries and recovery of electrolyte. The specific process is as follows:

[0039] First, open the feed plate, and put the waste power LiNi that has not undergone discharge pretreatment x co y mn z o 2 The battery and dry ice are mixed into the feed hopper at a mass ratio of 1:8. After the feeding is completed, the feed plate is closed and the 1 # automatic shutter and 2 # Automatic baffle, open the outlet valve and air extractor, at this time, the fixed reaction kettle and the electrolyte collection kettle are fully sealed;

[0040] The inert gas source is nitrogen, open the inlet valve and the inlet machine, and after a period of time, close the inlet machine, air extractor, inlet valve and outlet valve and 1 # automatic shutter and 2 # Automatic baffle, at this time, the fixed reactor is filled with nitrogen;

[0041] Turn on the roller shearing machine to start cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com