Copper-clad steel grounding rod, manufacturing method thereof and lightning protection grounding device

A manufacturing method, copper-clad steel technology, applied in the direction of connection, connection contact materials, electrical components, etc., can solve the problems of easy peeling off of the copper layer, residual electroplating solution, and high energy consumption in production, and achieve uniform distribution of the copper layer and save energy consumption. The effect of high material cost and heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

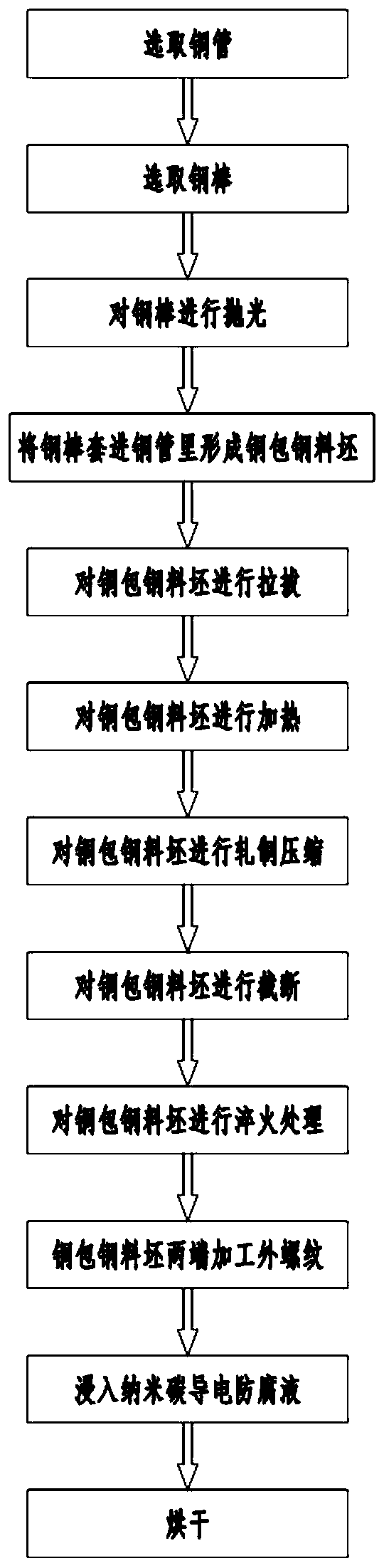

[0035] Such as figure 1 As shown, the hot-rolled manufacturing process of the ground rod is as follows:

[0036] The first step is to select a seamless copper tube with a thickness of 0.5-4mm, a diameter of 20-35mm, and a length of 3-5m, and clean the inner surface of the seamless copper tube to remove the seamless copper tube. Grease and dirt on the inner surface of the pipe. Of course, the copper tube material and copper tube size can be selected according to different specifications of ground rods to be manufactured, for example, silicon copper, phosphor bronze, common brass and other materials, so that the specifications of production can be standardized.

[0037] The second step is to select a steel rod suitable for the length of the seamle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com