Wheel hub motor and wheel hub motor heat dissipation system

A technology of in-wheel motor and motor shaft, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems that heat cannot be discharged in time and effectively, large heat of coil winding and motor casing, etc., to improve heat exchange efficiency. , save material, avoid the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

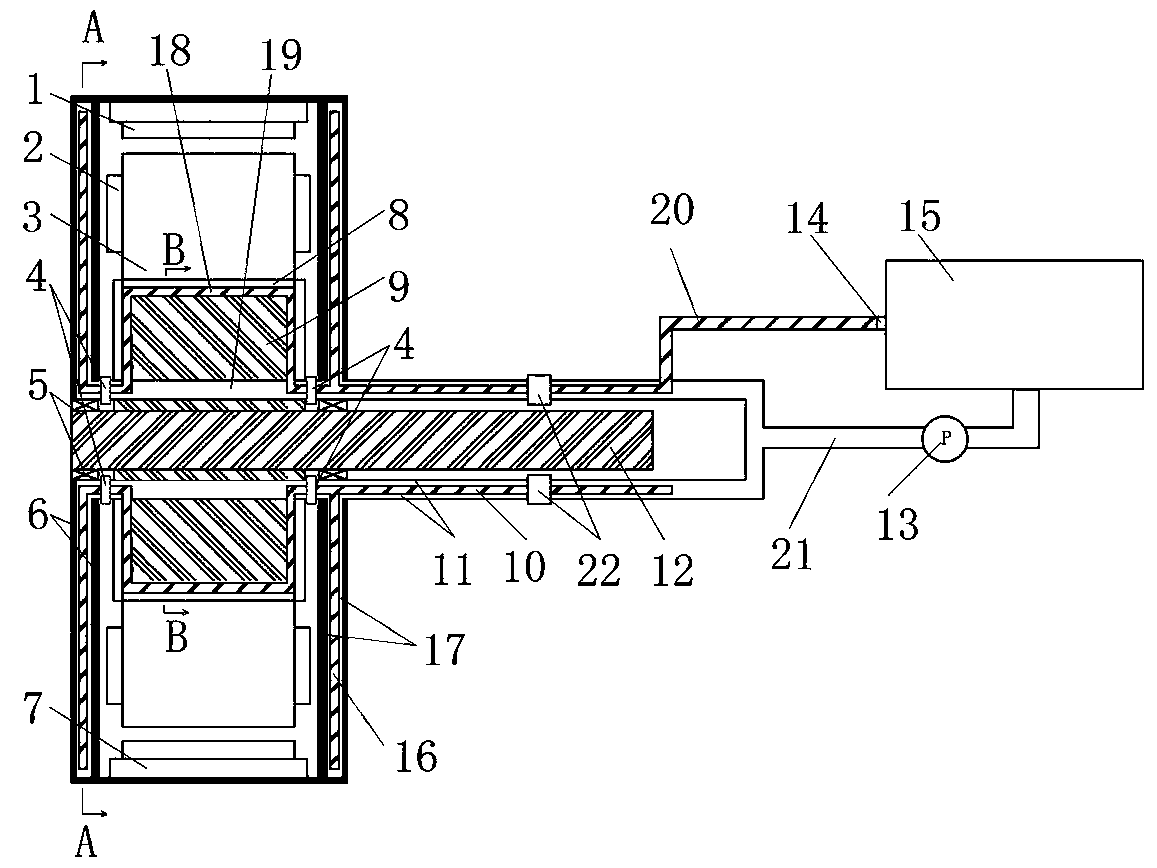

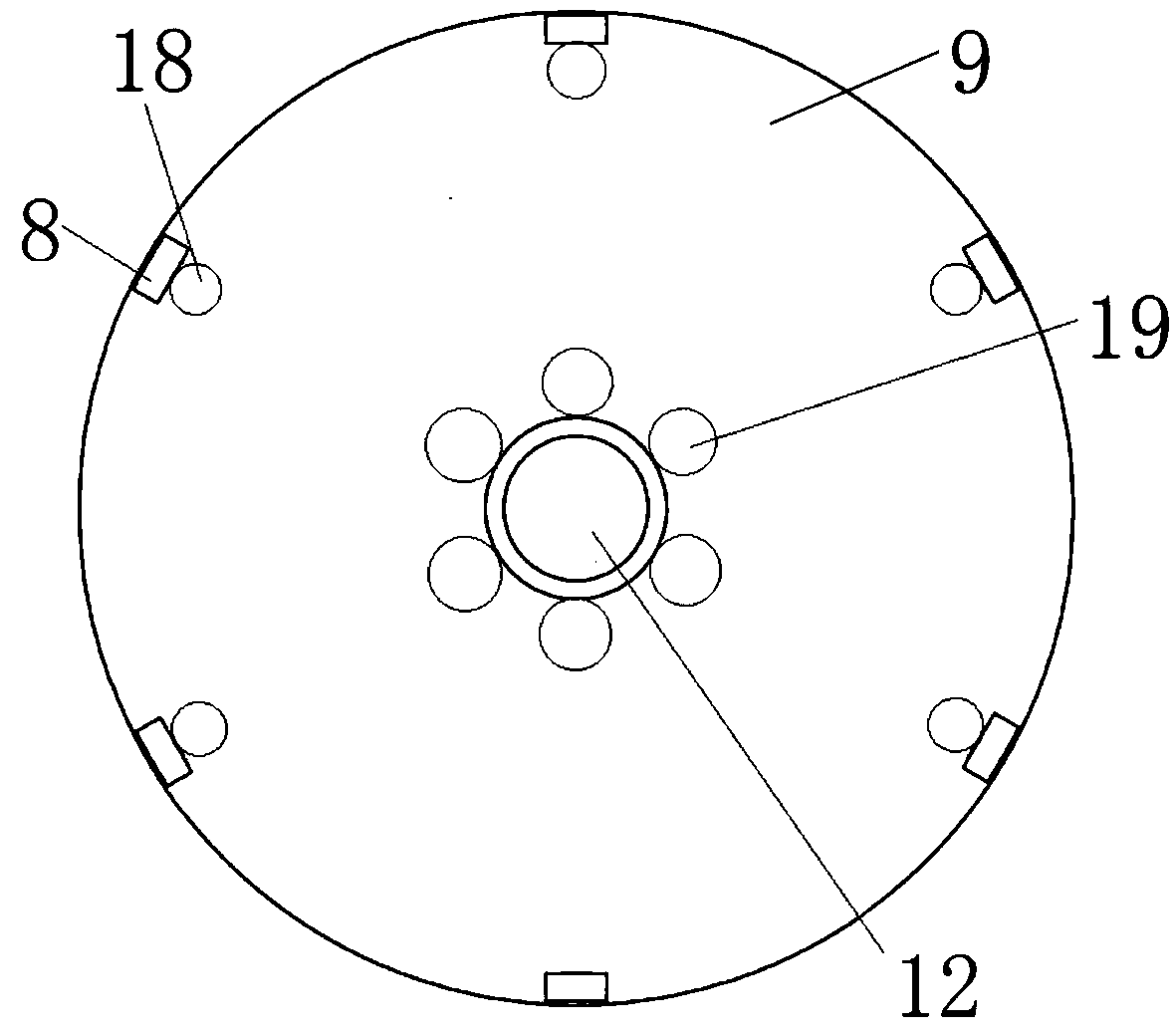

[0077] Such as figure 1 As shown, the hub motor cooling system includes the hub motor and the cooling water tank 15, a first pipeline 20 and a second pipeline 21 are arranged between the hub motor and the cooling water tank 15, one end of the first pipeline 20 is connected to the cooling water tank 15, and the other is connected to the cooling water tank 15. One end is connected to the liquid inlet pipeline of the hub motor through the outer rotary joint 22 , one end of the second pipeline 21 is connected to the cooling water tank 15 , and the other end is connected to the liquid outlet pipeline of the hub motor through the outer rotary joint 22 . Wherein, the first pipeline 20 is provided with a water tank valve 14 , and the second pipeline 21 is provided with a circulation pump 13 .

[0078] In this embodiment, one end of the first pipeline 20 connected to the outer rotary joint 22 and one end of the second pipeline 21 connected to the outer rotary joint 22 are ring structur...

specific Embodiment 2

[0091] The difference from the specific embodiment 1 is that in embodiment 1, a heat-conducting copper bar is provided on the outer peripheral surface of the stator liquid inlet channel to improve the heat exchange efficiency. The copper bar is coated with a heat conduction layer on the outer peripheral surface of the stator liquid inlet channel to improve heat exchange efficiency.

specific Embodiment 3

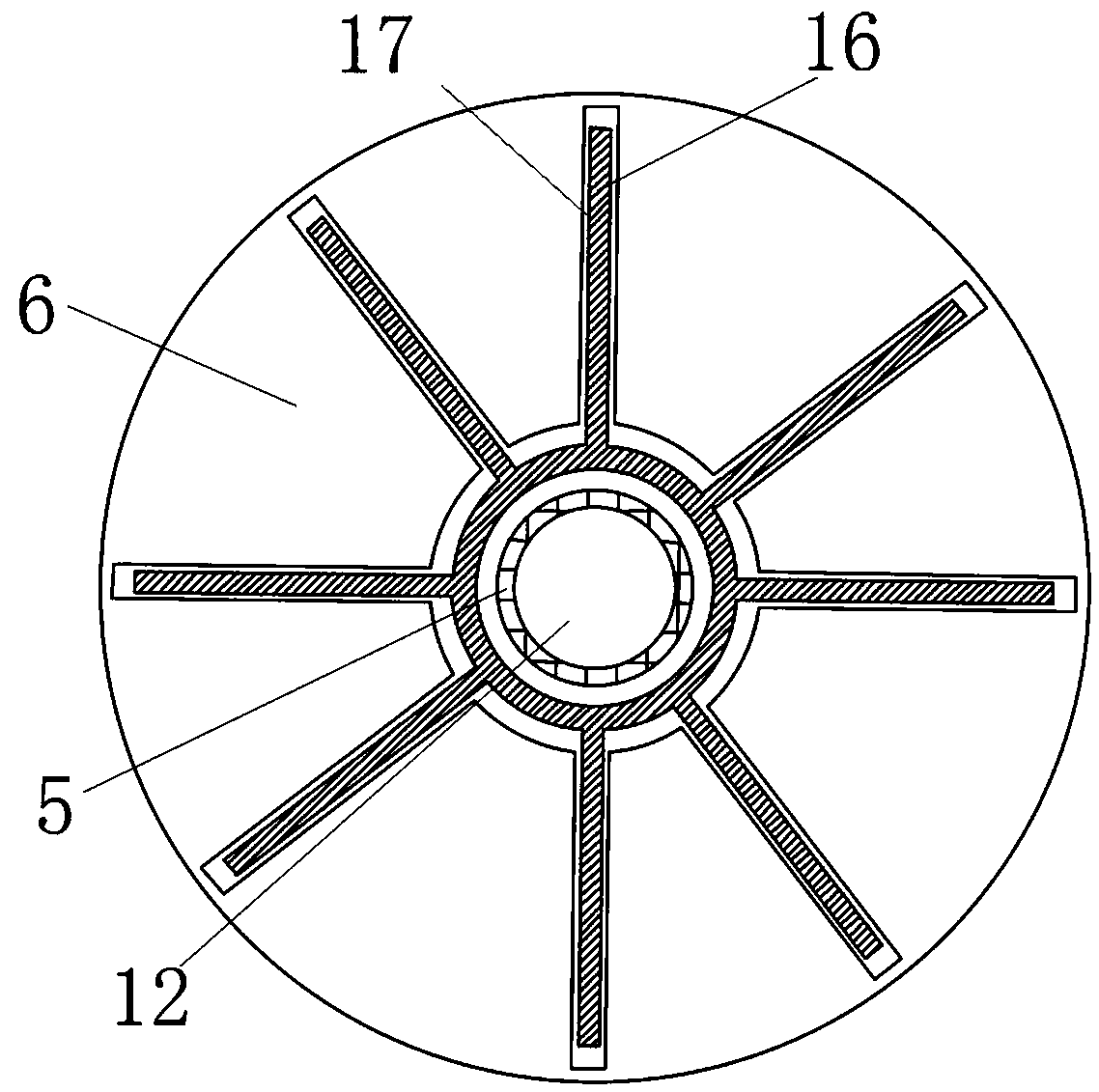

[0093] The difference from the specific embodiment 1 is that in embodiment 1, a blind hole is provided on the motor housing 6, and the blind hole extends radially along the motor shaft 12, and the end of the blind hole away from the motor shaft 12 is a blind end, and the blind hole constitutes a The liquid outlet channel of the casing. In this embodiment, a blind hole is provided on the motor casing, and a pipeline with one end closed and one end open is arranged in the blind hole, and the pipeline in the blind hole constitutes the casing liquid outlet channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com