Preparation and application of cocoa butter low-melting point fraction organic oil gel

A technology of organogel and cocoa butter, which is applied in the fields of application, food science, edible oil/fat, etc., can solve the problems of waste of raw materials, etc., and achieve the effect of simple preparation process, easy control of production conditions, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

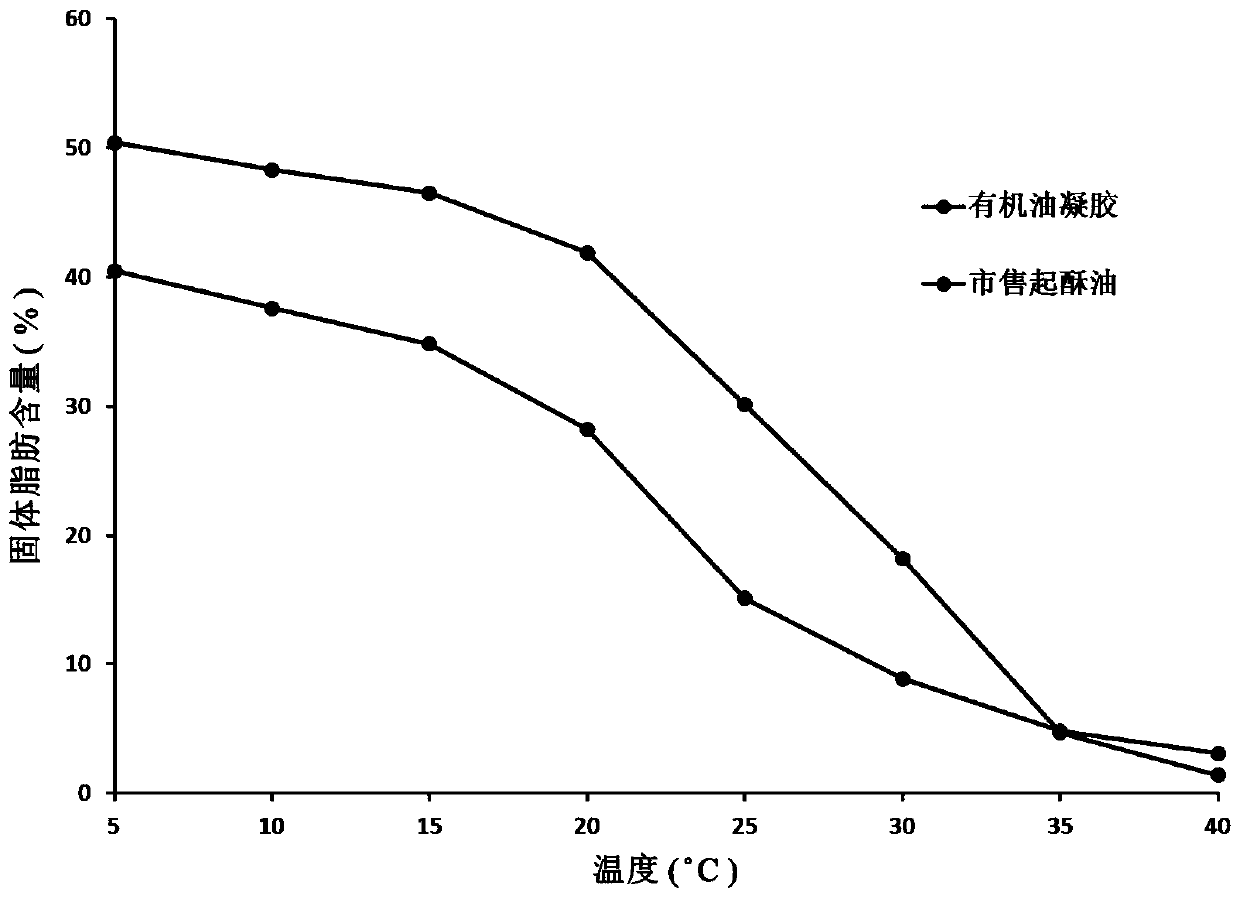

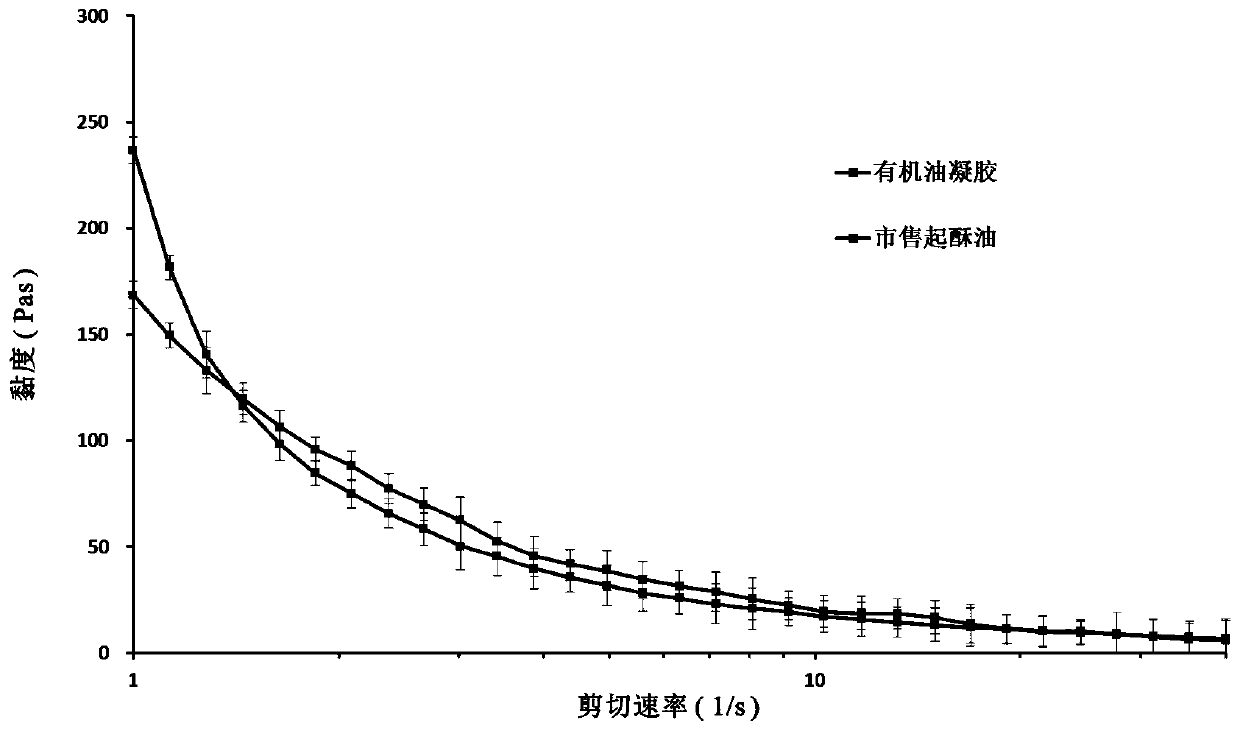

[0028] The present invention uses the low-melting point fraction of cocoa butter to improve the characteristics of traditional rice bran wax-corn oil gel, so that it has similar characteristics to commercially available shortening, thereby preparing a new type of organic oil gel that can replace traditional shortening :

[0029] (1) Put 100g of cocoa butter in a glass beaker and heat at 80°C for 30min. Place the melted cocoa butter in a constant temperature incubator at 24°C. Measure the solid fat content of cocoa butter every half hour. When the solid fat content reached 20%, the cocoa butter was centrifuged for 5 minutes at a speed of 10000 rpm in a centrifuge. Pour off the liquid cocoa butter in the centrifuge tube immediately after centrifugation. The solidified cocoa butter was washed three times with 50 mL of isobutanol. Collect all washes. The solvent of the washing solution was removed by a rotary evaporator at 60°C. The sample after removal of the washing liquid...

Embodiment 2

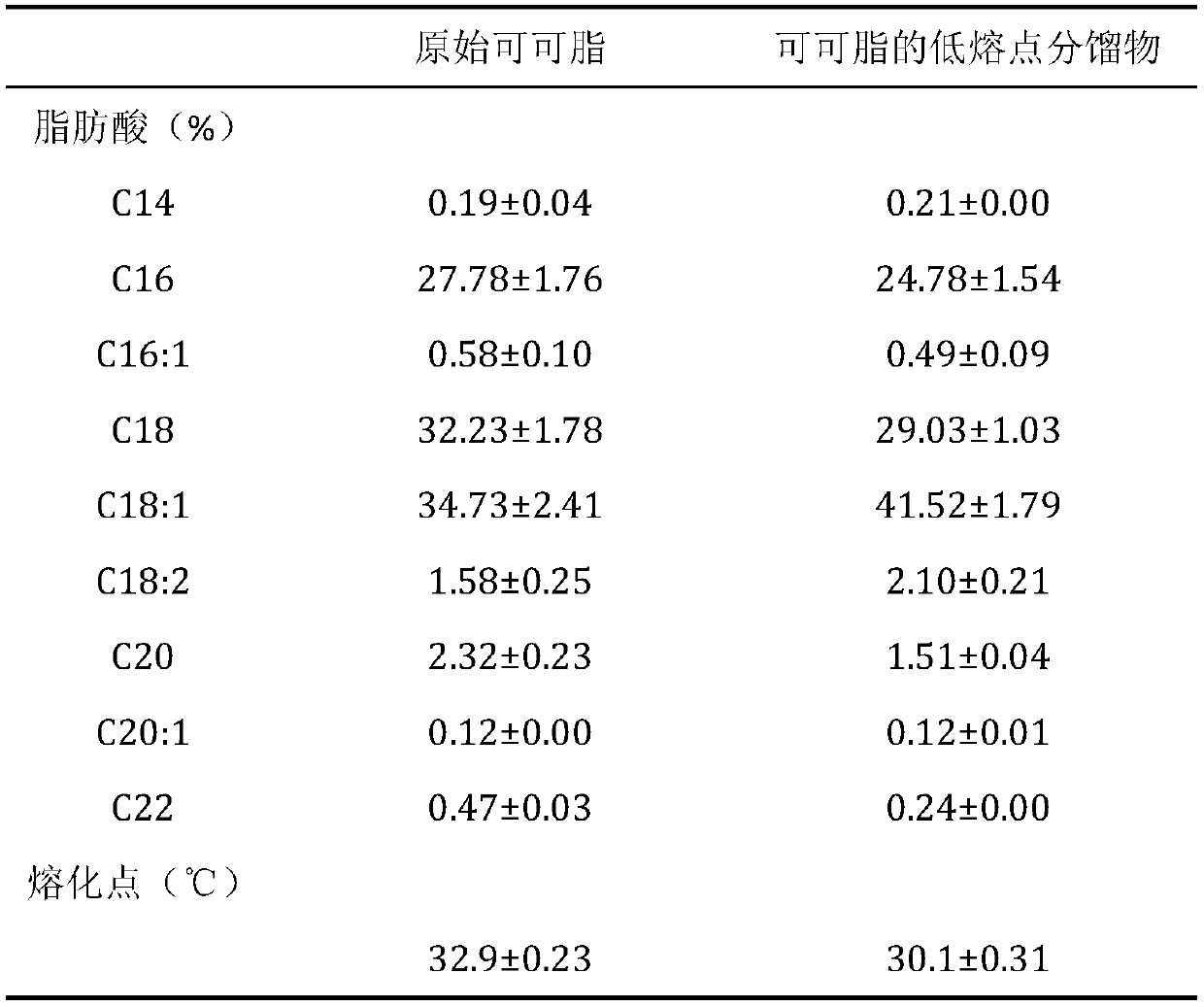

[0041] (1) Put 100g of cocoa butter in a glass beaker and heat at 80°C for 30min. Place the melted cocoa butter in a constant temperature incubator at 24°C. Measure the solid fat content of cocoa butter every half hour. When the solid fat content reached 20%, the cocoa butter was centrifuged for 5 minutes at a speed of 10000 rpm in a centrifuge. Pour off the liquid cocoa butter in the centrifuge tube immediately after centrifugation. The solidified cocoa butter was washed three times with 50 mL of isobutanol. Collect all washes. The solvent of the washing solution was removed by a rotary evaporator at 60°C. The sample after removal of the washing liquid is mixed with the liquid cocoa butter that was previously poured off. This portion of liquid cocoa butter is considered the low melting fraction of cocoa butter. The fatty acid composition and melting point of raw cocoa butter and its low-melting fractions were determined by gas chromatography-mass spectrometry and differ...

Embodiment 3

[0045] (1) Put 100g of cocoa butter in a glass beaker and heat at 80°C for 30min. Place the melted cocoa butter in a constant temperature incubator at 24°C. Measure the solid fat content of cocoa butter every half hour. When the solid fat content reached 20%, the cocoa butter was centrifuged for 5 minutes at a speed of 10000 rpm in a centrifuge. Pour off the liquid cocoa butter in the centrifuge tube immediately after centrifugation. The solidified cocoa butter was washed three times with 50 mL of isobutanol. Collect all washes. The solvent of the washing solution was removed by a rotary evaporator at 60°C. The sample after removal of the washing liquid is mixed with the liquid cocoa butter that was previously poured off. This portion of liquid cocoa butter is considered the low melting fraction of cocoa butter. The fatty acid composition and melting point of raw cocoa butter and its low-melting fractions were determined by gas chromatography-mass spectrometry and differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com