Production process for producing active protein chicken feed from maggots

An active protein and production technology technology, applied in the field of chicken feed production technology, can solve the problems of low bacterial colony content of finished feed and short shelf life of finished feed, so as to reduce disease and enteritis, health care and regulation of intestinal function, stimulation The effect of mucosal immune function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A production process for producing active protein chicken feed with maggots, the steps are as follows:

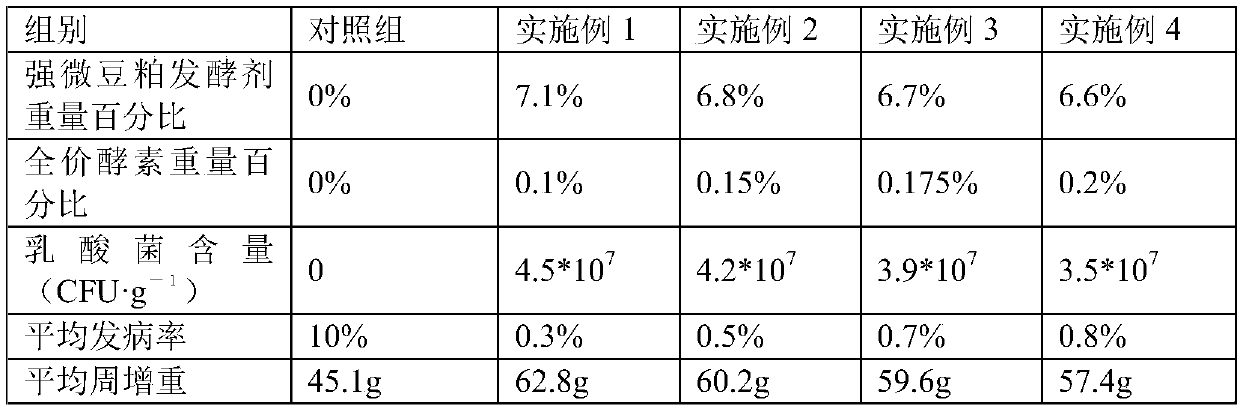

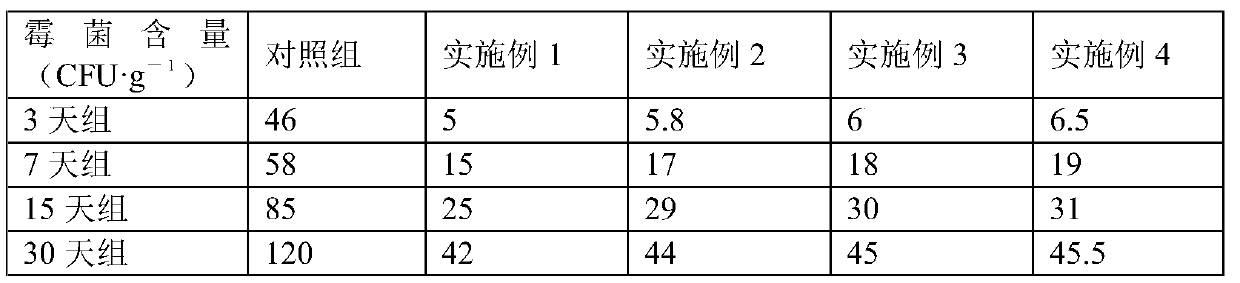

[0016] (1), preparation of fermented soybean meal: the ratio of parts by weight is 2-4:0.001-0.002:1-2 (Example 1 is 2:0.001:1, Example 2 is 3:0.0015:1.5, Example 3 Be 3.5:0.00175:1.75, embodiment 4 is 4:0.002:2) soybean meal, strong micro soybean meal starter and water are 200-300rpm (embodiment 1 is 200rpm, embodiment 2 is 250rpm, embodiment 3 is 275rpm, embodiment 4 is 300rpm) stirrer 30-50min (embodiment 1 is 50min, embodiment 2 is 40min, embodiment 3 is 45min, embodiment 4 is 30min), then sends in fermenter, at temperature For 20-25 ℃ (20 ℃ for embodiment 1, 25 ℃ for embodiment 4) down anaerobic fermentation 6-7 days (7 days for embodiment 1, 6 days for embodiment 4) or 26-30 ℃ (implementation Example 2 is 26 ℃, embodiment 3 is 30 ℃) under anaerobic fermentation 3-4 days (embodiment 2 is 4 days, embodiment 3 is 3 days) (there is obvious alcohol smell), makes de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com